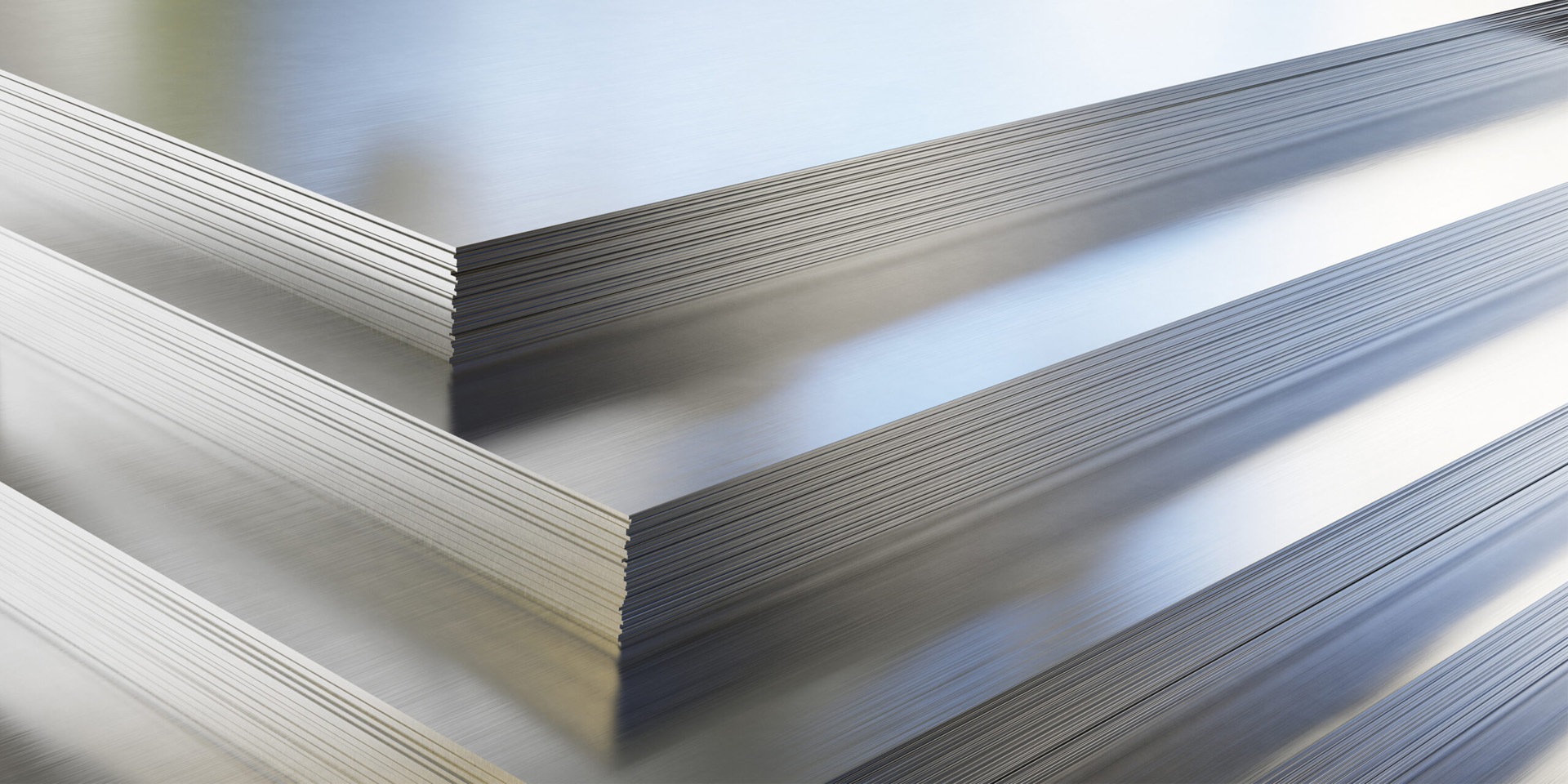

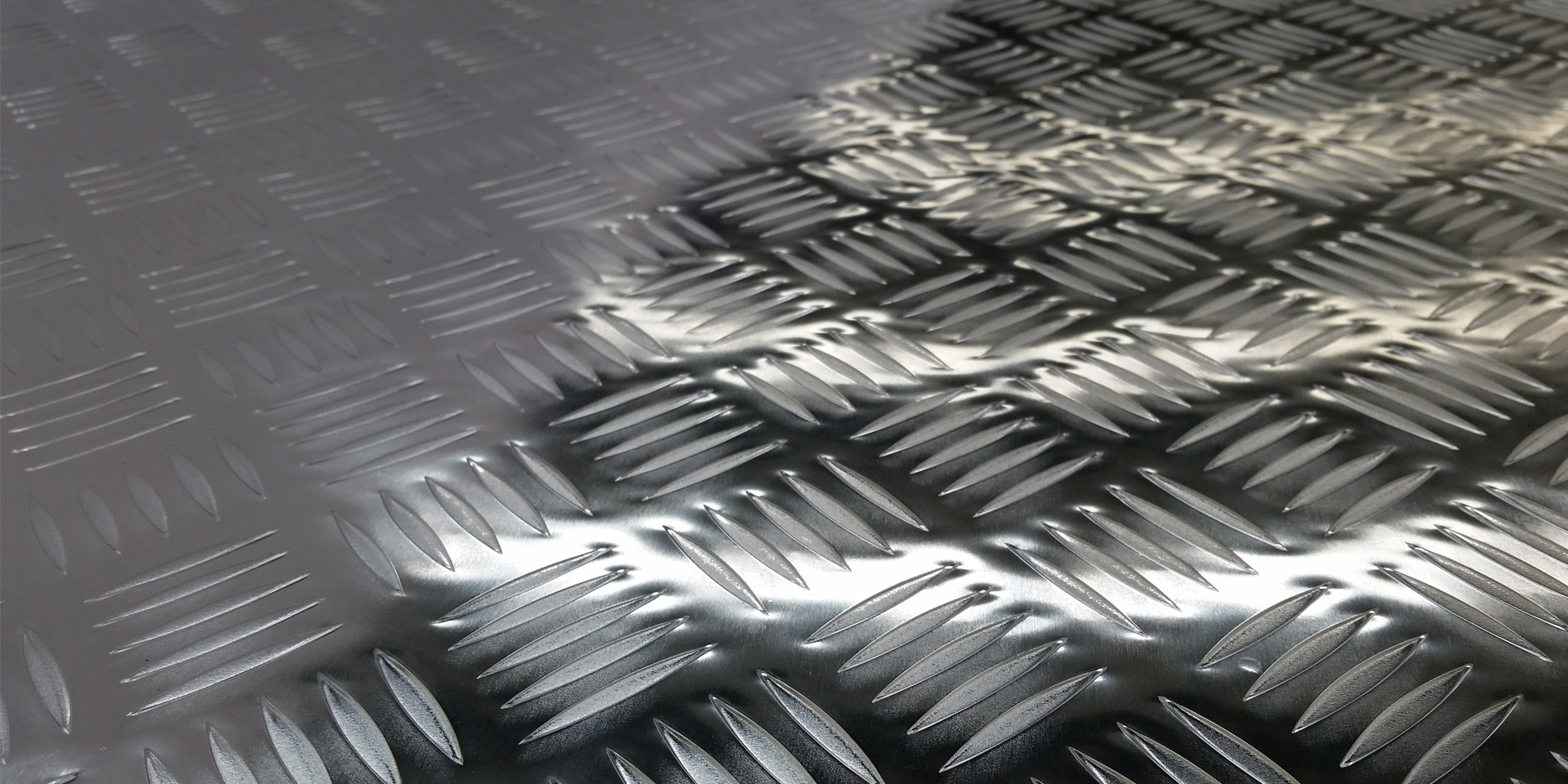

6061 Aluminum Sheet

6061 aluminum sheet is a widely used medium-strength Al-Mg-Si alloy. It is heat-treatable and exhibits excellent corrosion resistance, weldability, and machinability, making it suitable for construction, marine, automotive, and aerospace industries.

MESSAGE

Overview

6061 aluminum sheet is a premium alloy material manufactured via heat treatment and pre-stretching processes. While its strength is not as high as that of 2000-series or 7000-series aluminum alloys, 6061 aluminum alloy is primarily composed of magnesium (Mg) and silicon (Si)—endowing it with superior processability, exceptional weldability and electroplating compatibility, good corrosion resistance, and high toughness. Notably, the dense structure of 6061 aluminum sheet allows it to maintain its shape without deformation post-processing. Additionally, this alloy is easy to polish, can form colored films, and delivers excellent oxidation results. Given these properties, it is clear that 6061 aluminum sheet is an ideal material for producing precision machinery, automotive wheels, 3C products, mobile phone cases, molds, trolley cases, and alloy doors and windows.

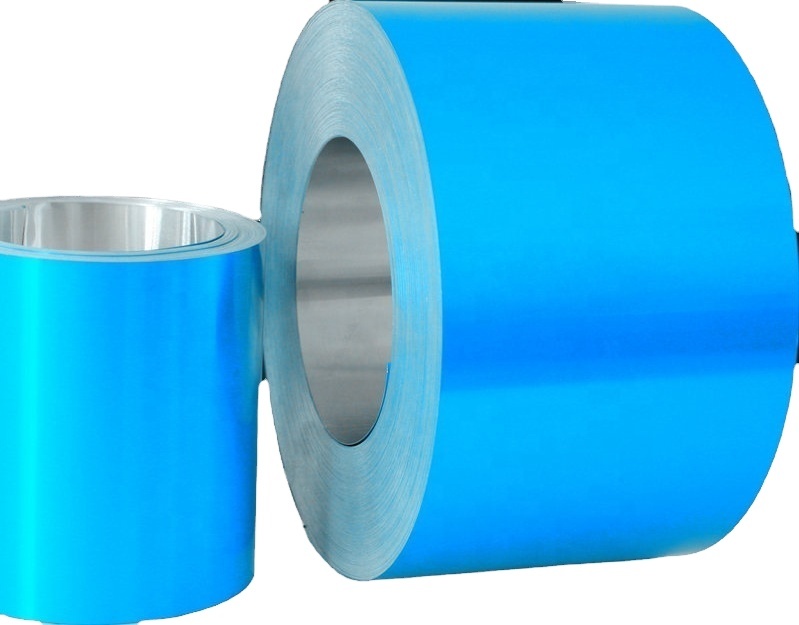

Specification

Alloy: 6061

Temper: O, T4, T6, T651, H112

Thickness: 0.1mm-400mm

Width: 600mm-4300mm

Length: Max 12000mm

Surface Treatment: Anodizing, Coating

Feature

1.Heat-treatable Strengthening: Capable of being strengthened via heat treatment, with T6 temper delivering optimal strength to meet medium-to-high load-bearing requirements of structural components.

2.Balanced Mechanical Performance: Integrates high strength, good toughness, and excellent ductility, avoiding the trade-off between strength and processability common in single-performance alloys.

3.Superior Weldability: Compatible with MIG, TIG, resistance welding, and other methods; welded joints maintain high strength and corrosion resistance without obvious performance degradation.

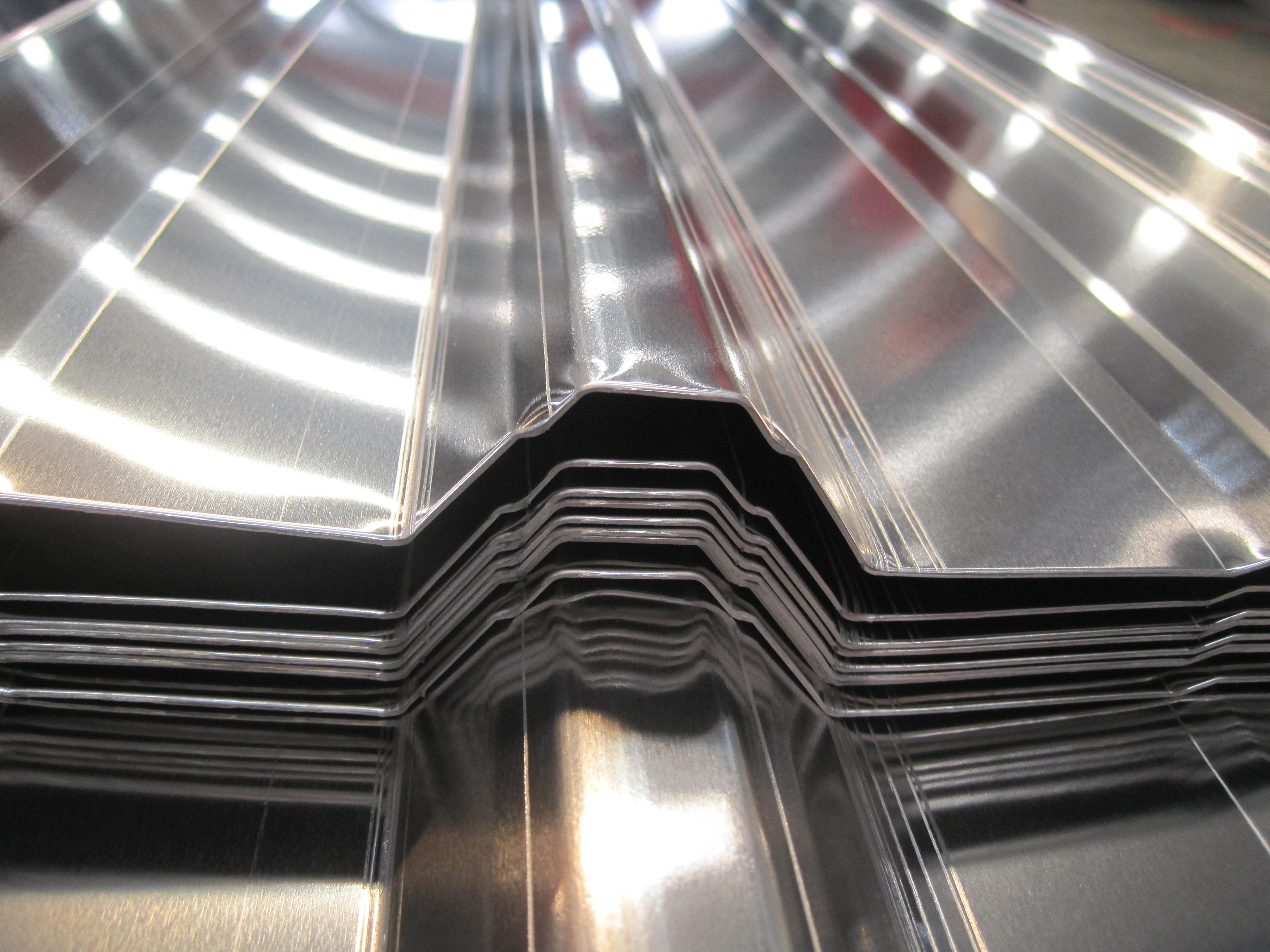

4.Excellent Formability & Machinability: Easy to bend, stamp, roll, and machine into complex shapes; low cutting resistance ensures high processing efficiency and dimensional precision.

5.Reliable Corrosion Resistance: Resists atmospheric corrosion, fresh water erosion, and mild chemical corrosion; anodizing or coating can further enhance resistance to harsh environments (e.g., coastal, industrial).

6.Excellent Oxidation Effect: Easy to form uniform and dense oxide films through anodizing, enabling coloring and enhancing surface hardness and wear resistance.

Application

6061 aluminum plate is widely applied in architecture (curtain walls, frames), transportation (automotive/aviation parts), industrial manufacturing (machinery components), electronics (heat sinks, casings), and high-end products like sports equipment and medical devices.

NEXT

NEXT

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!