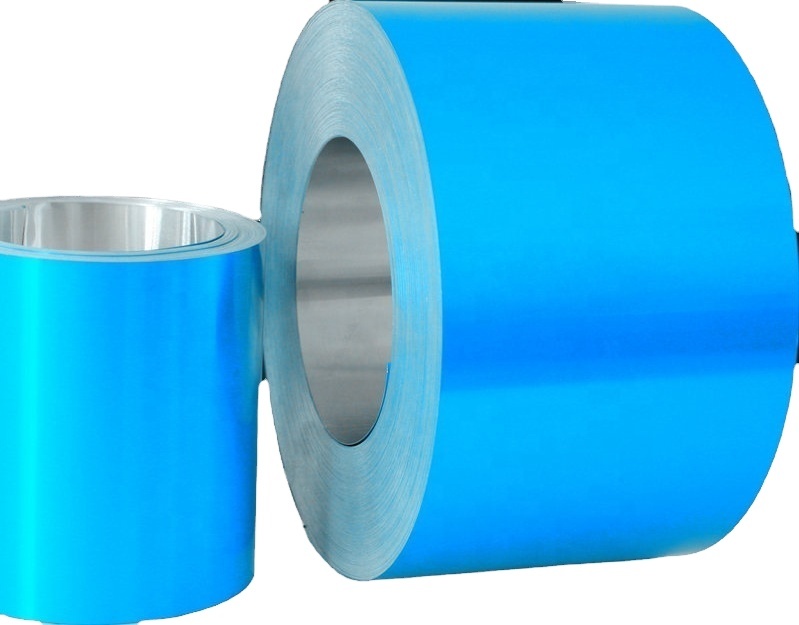

Aluminum Coil for Beverage Bottle Caps

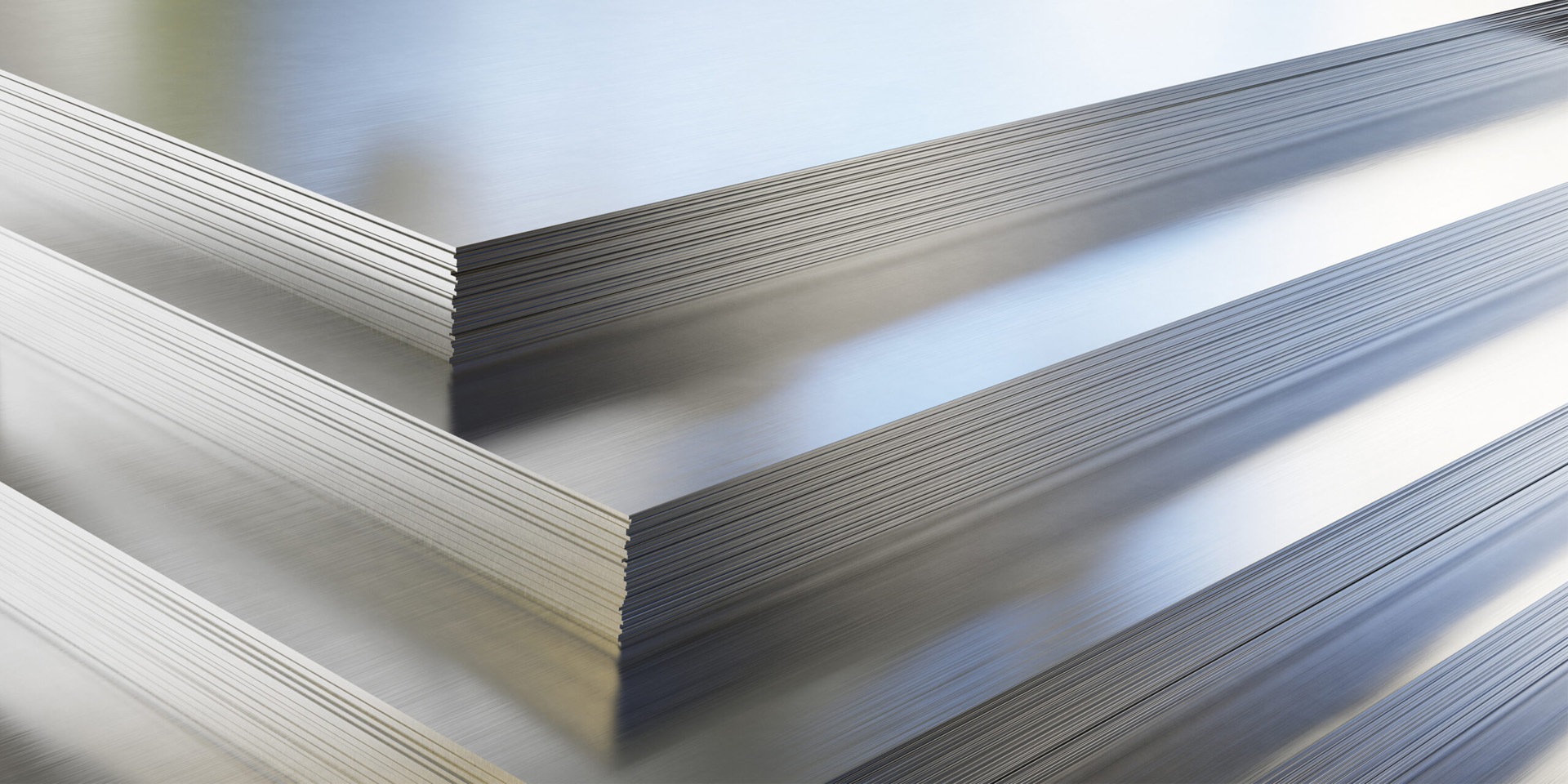

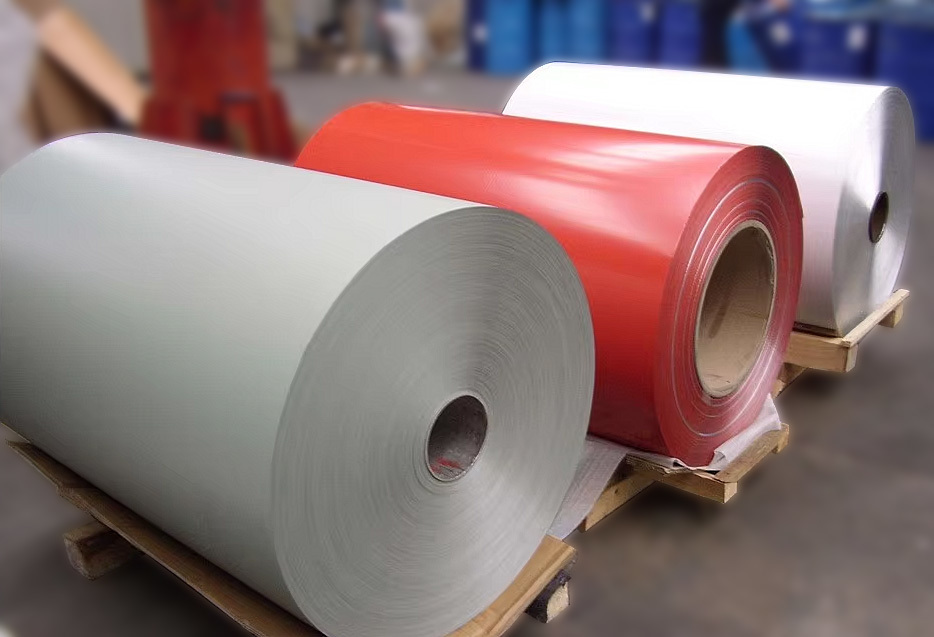

Aluminum coil for beverage bottle caps are high-performance aluminum alloy materials specifically designed for bottle cap manufacturing. Processed through stamping and deep drawing, they are widely used in beverage industries. Key advantages include lightweight, corrosion resistance, strong sealing performance, recyclability, and compliance with food safety standards.

MESSAGE

Overview

Aluminum beverage bottle caps are crafted from high-grade special aluminum alloy materials and are primarily used for packaging wines and beverages (both carbonated and non-carbonated), meeting specialized requirements such as high-temperature sterilization and cooking processes. Currently, approximately 50% of beverage bottle caps in China are made from aluminum materials. Compared to plastic caps, aluminum caps not only offer superior performance but also feature lower costs, zero pollution, and recyclability.

Specification

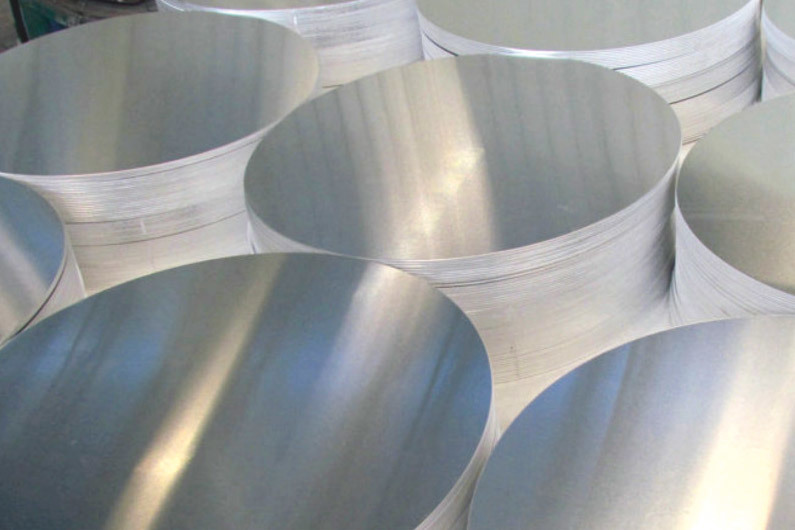

Alloy: 8011

Temper: H13, H14, H16, H18

Thickness: 0.012-0.5mm

Width: 100-1600mm

Feature

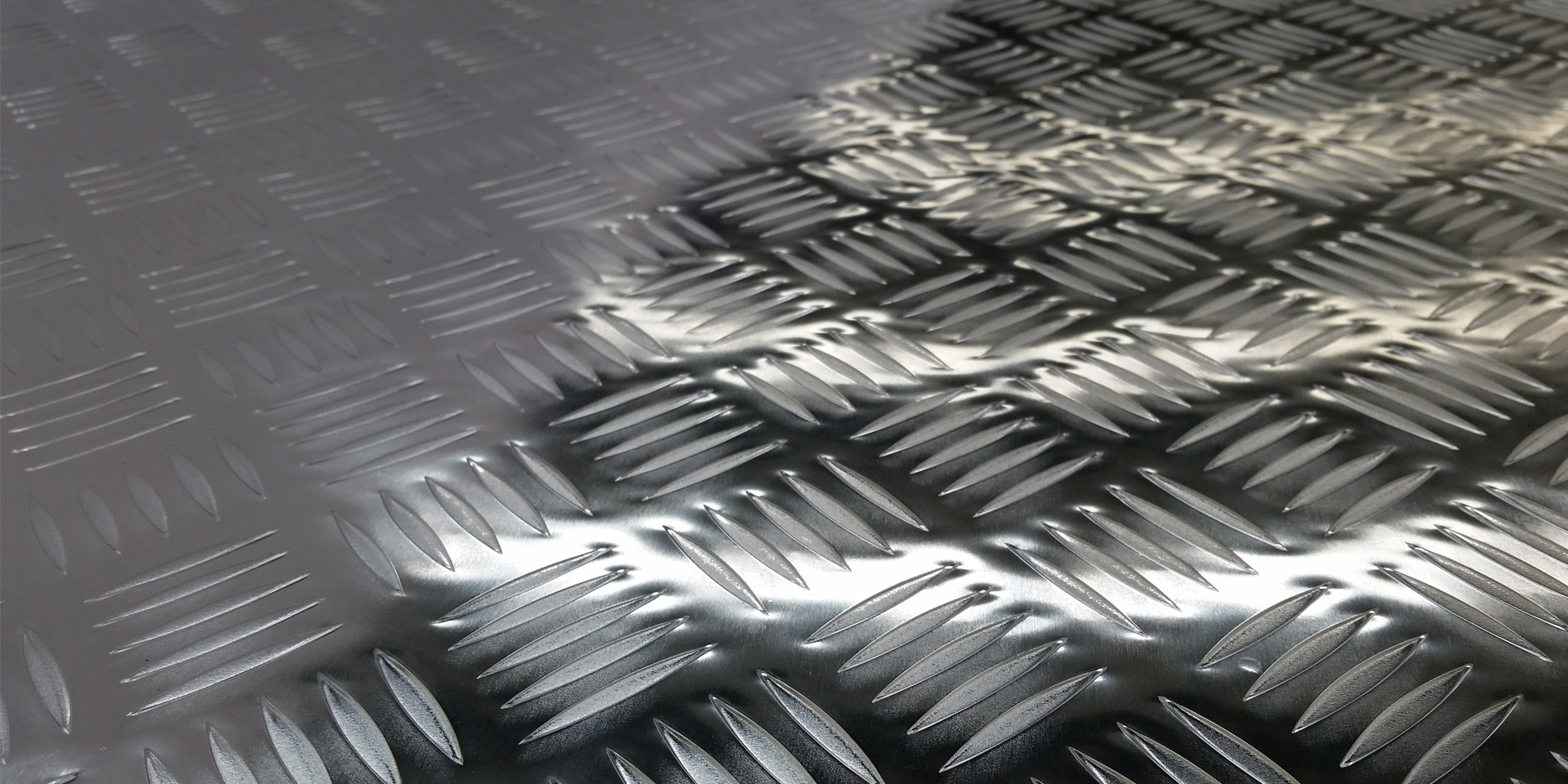

1. Flat and Uniform Surface Texture: The aluminum coil features a smooth and flat texture, with a clean sheet surface and relatively uniform color, delivering excellent visual and tactile quality.

2. Comprehensive Hygiene Compliance: Hygiene and safety are fully guaranteed; the product is free of spots, voids, and other defects, meeting the hygiene requirements for food contact and packaging applications.

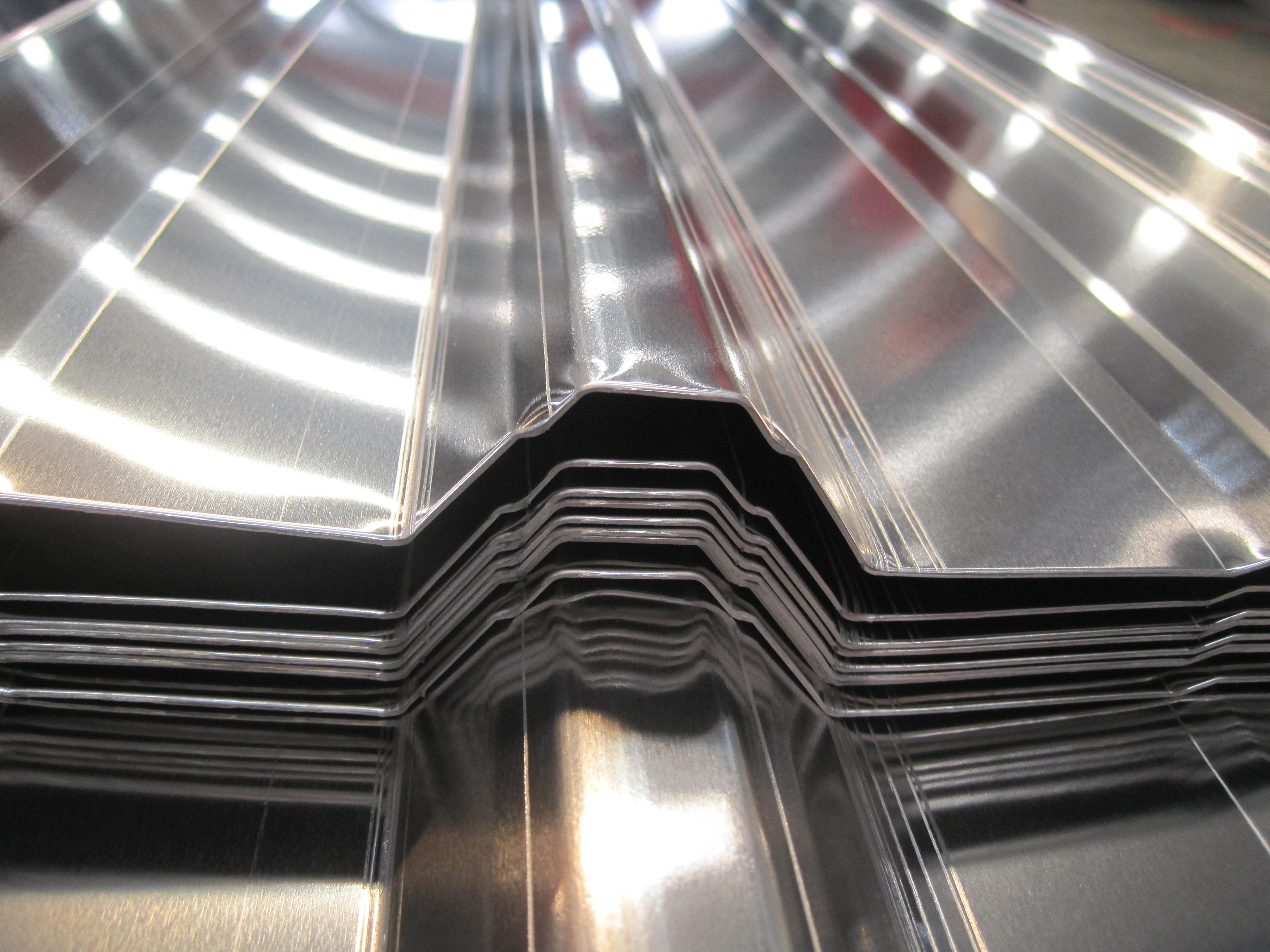

3. Superior Barrier & Protection Performance: It boasts reliable moisture resistance, strong barrier capacity against various media, and excellent light-shielding performance, effectively protecting the contents inside.

4. Outstanding Mechanical Properties: It exhibits excellent and stable mechanical performance, with high blast resistance, as well as strong resistance to puncture and tearing, ensuring long-lasting durability.

5. Prominent Safety & Cleanliness Traits: Non-toxic and odorless, the product is safe and hygienic. After degreasing treatment, it achieves high cleanliness without residual impurities, suitable for high-standard application scenarios.

6. Processing Adaptability & Application Value: Complying with Water Brushing Grade A standards, the product offers a low ear removal rate, high cup convexity, and excellent aluminum coil strength, ensuring good airtightness after compounding. After undergoing processing such as compounding, printing, and gluing, it can be widely used as packaging material across various fields.

Application

PREV

NEXT

PREV

NEXT

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!