Aluminum Sheet for Roofing

In the international building sector, the selection of roofing materials exerts a direct influence on a structure’s durability, upkeep expenses, and eco-friendly performance. Over the past few years, aluminum roofing sheets have gradually become a mainstream substitute for conventional steel roofing, owing to their lightweight property, corrosion resistance, and prolonged service life. Whether applied in residential, commercial, or industrial projects, these sheets are capturing substantial market share and have emerged as a key focus for overseas contractors and property owners.

MESSAGE

Overview

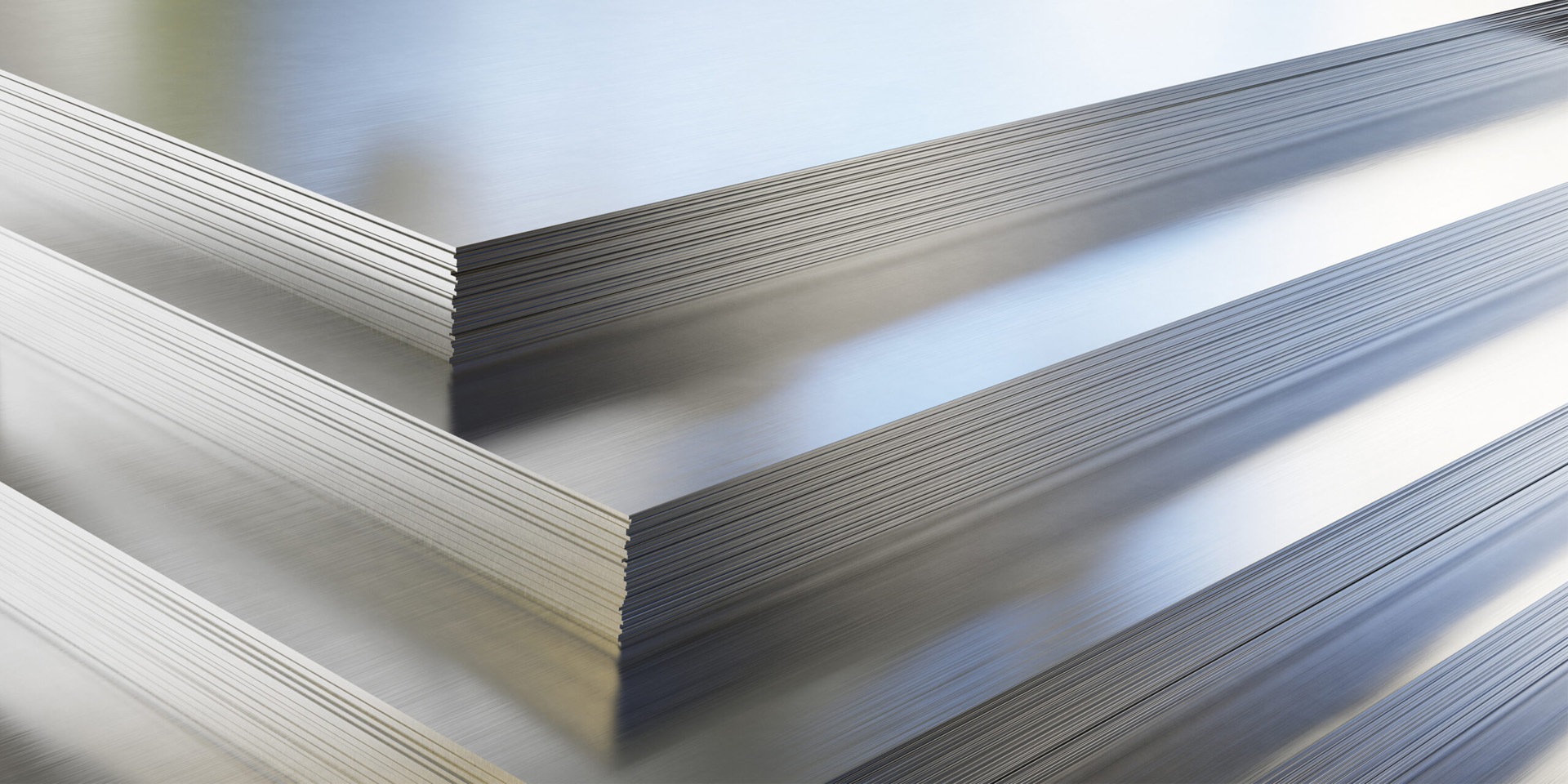

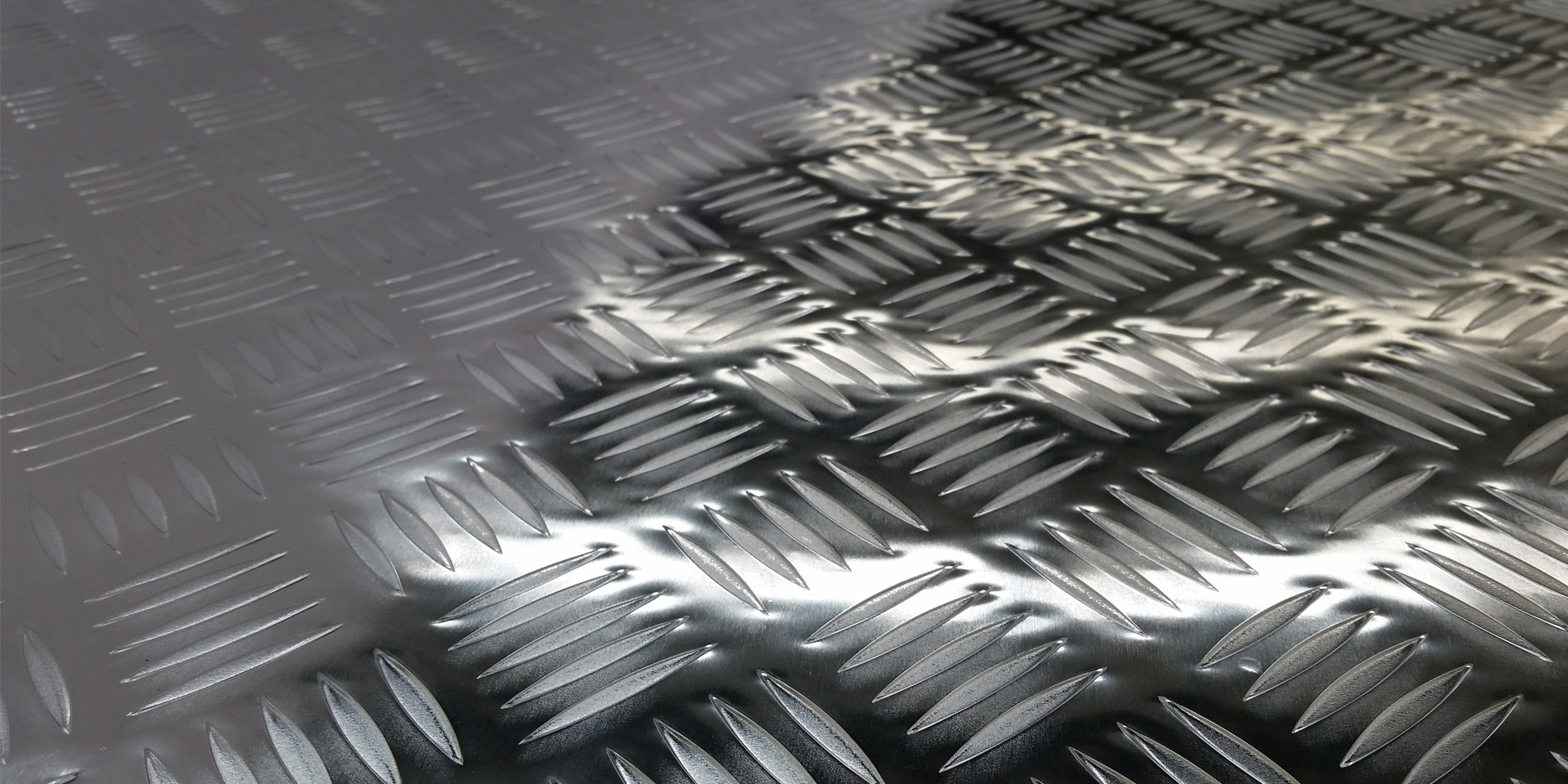

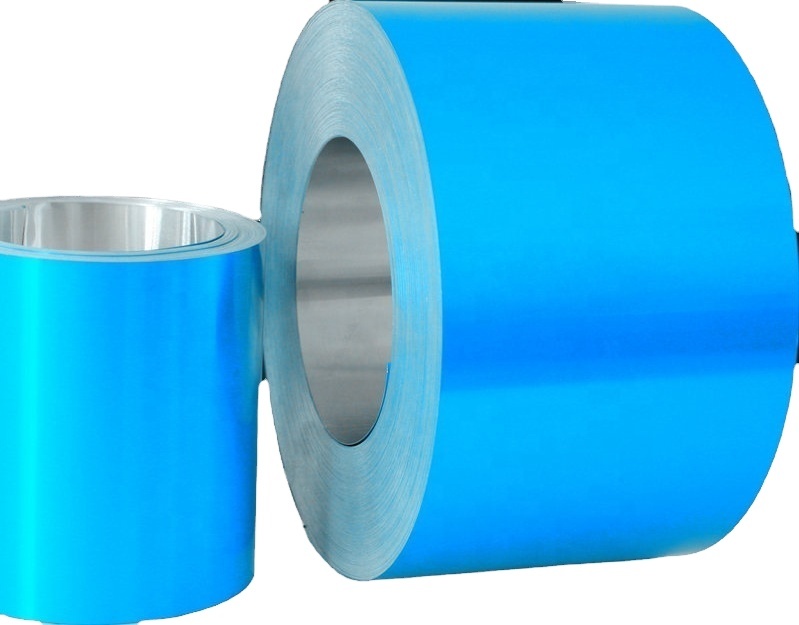

An aluminum sheet for roofing is a lightweight, durable roofing material made from aluminum alloy through processes such as rolling, forming, and surface treatment. Its key advantages include corrosion resistance, lightweight, ease of processing, and environmental friendliness. It is widely used in industrial plants, commercial buildings, residential houses, and temporary structures. Compared to traditional materials, aluminum sheets offer longer service life and lower maintenance costs, making them a preferred choice for modern roofing.

Specification

Alloy: 3003, 3004, 5052, etc

Temper: HO, H12, H14, H16, H18, H22, H24, H26

Thickness: 0.3-1.5mm

Width: 600mm-1200mm

Length: Max 11000mm

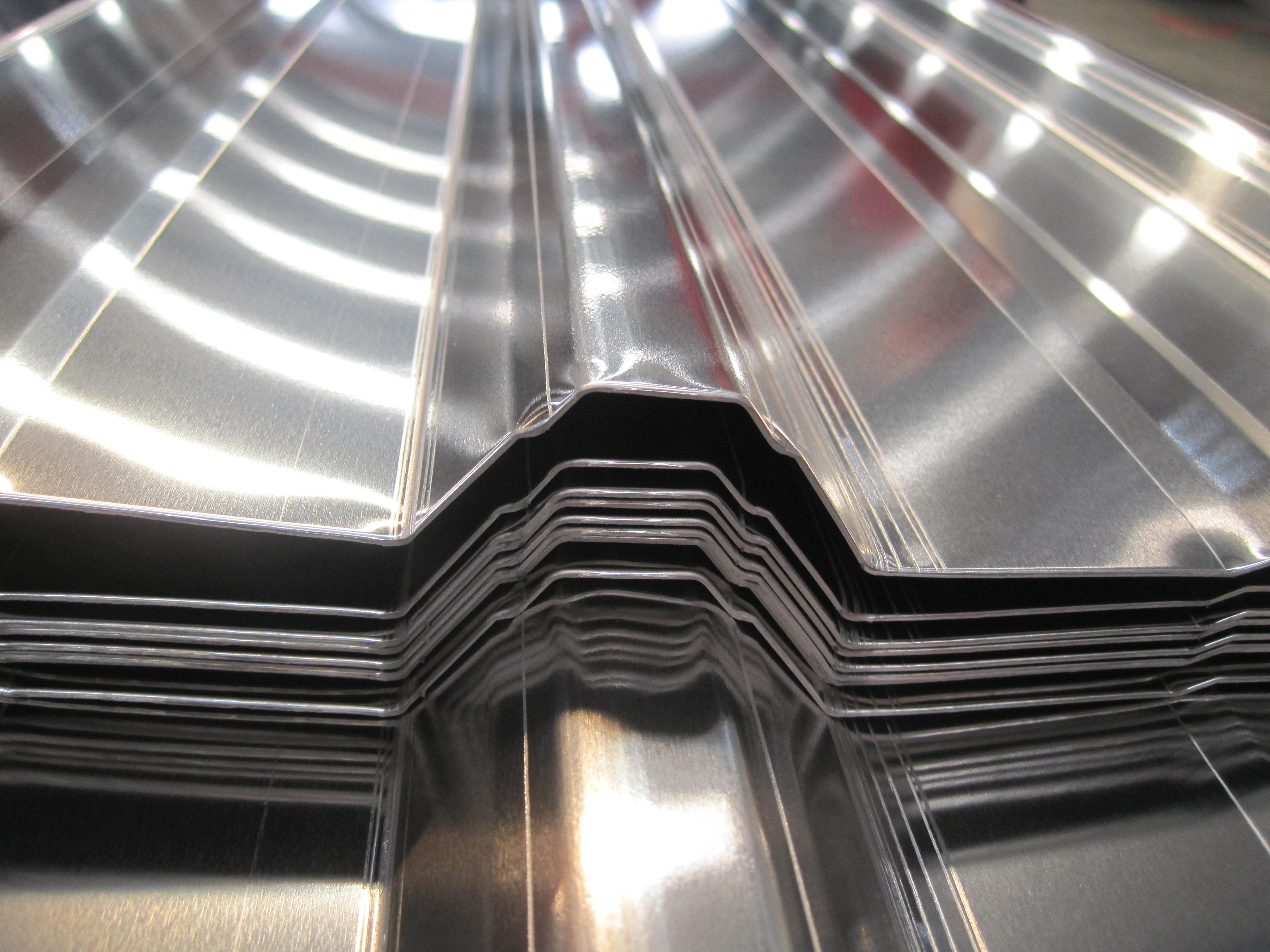

Pattern: 35-125-750,25-210-840,14-63.5-825,35-125-900

Feature

1.Corrosion Resistance: Though steel roofing delivers exceptional strength, extended exposure to moisture, acid rain, or coastal conditions renders it prone to rust and corrosion—requiring regular rust-inhibiting coatings or full replacements. In contrast, aluminum roofing sheets inherently form a protective oxidized film that effectively blocks water and oxygen penetration. Even without extra protective layers, they resist salt spray erosion and acid rain damage, making them perfectly suited for areas with fluctuating climates or high humidity levels. This inherent corrosion resistance substantially lowers long-term maintenance costs for property owners.

2.Lightweight Design: Boasting a density merely one-third of steel’s, aluminum roofing sheets reduce structural load pressures—an advantage particularly valuable for renovating older buildings or implementing weight-restricted architectural designs. Their lightweight property also facilitates transportation and installation processes, cutting down on labor requirements and project timelines. By comparison, steel roofing demands more intricate support frameworks and specialized equipment during the installation phase.

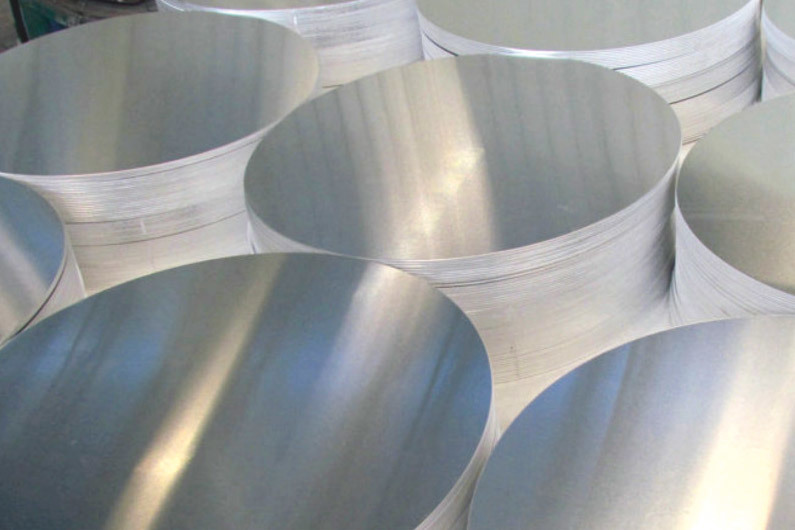

3.Excellent Formability and Processability: Easy to cut, bend, stamp and weld, can be accurately processed into various roofing shapes such as flat panels, corrugated panels, arc panels and special-shaped panels, adapting to the roofing design needs of different architectural styles.

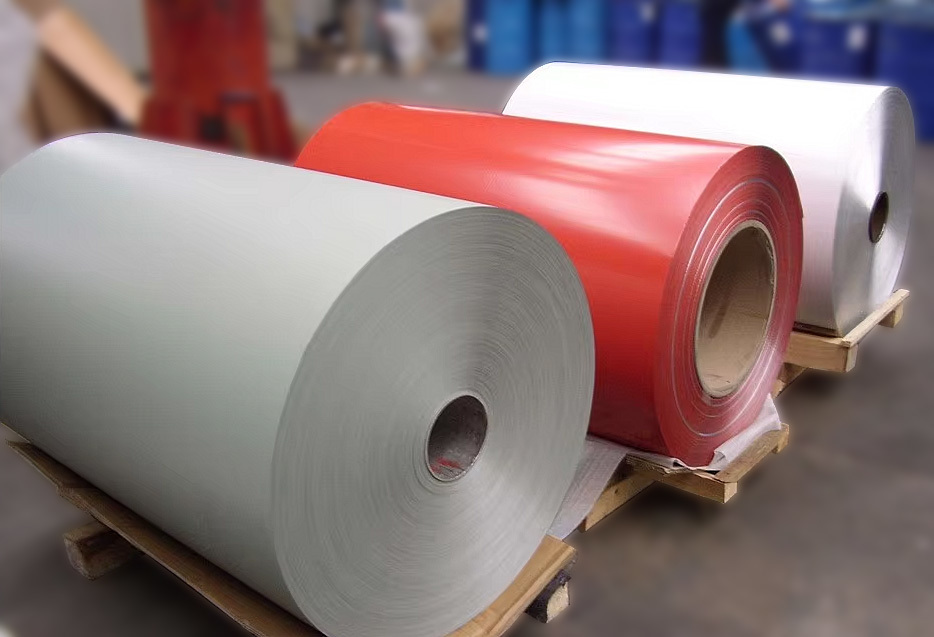

4.Diverse Decorative Effects: Supports various surface effects such as multi-color coating, metallic texture, matte/bright finish, which can realize the style unity of the roof and the building facade, enhancing the overall aesthetic texture of the building.

5.Eco-Friendliness and Sustainability: Aluminum is fully recyclable, with the energy consumed in recycling accounting for just 5% of that needed for primary aluminum production. Selecting aluminum roofing aligns with global green building initiatives while reducing resource wastage. Furthermore, these sheets offer a service life of over 30 years, significantly outperforming the average durability of steel roofing. This extended lifespan further minimizes carbon emissions throughout the product’s lifecycle, enhancing its environmental credentials.

Application

PREV

PREV

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!