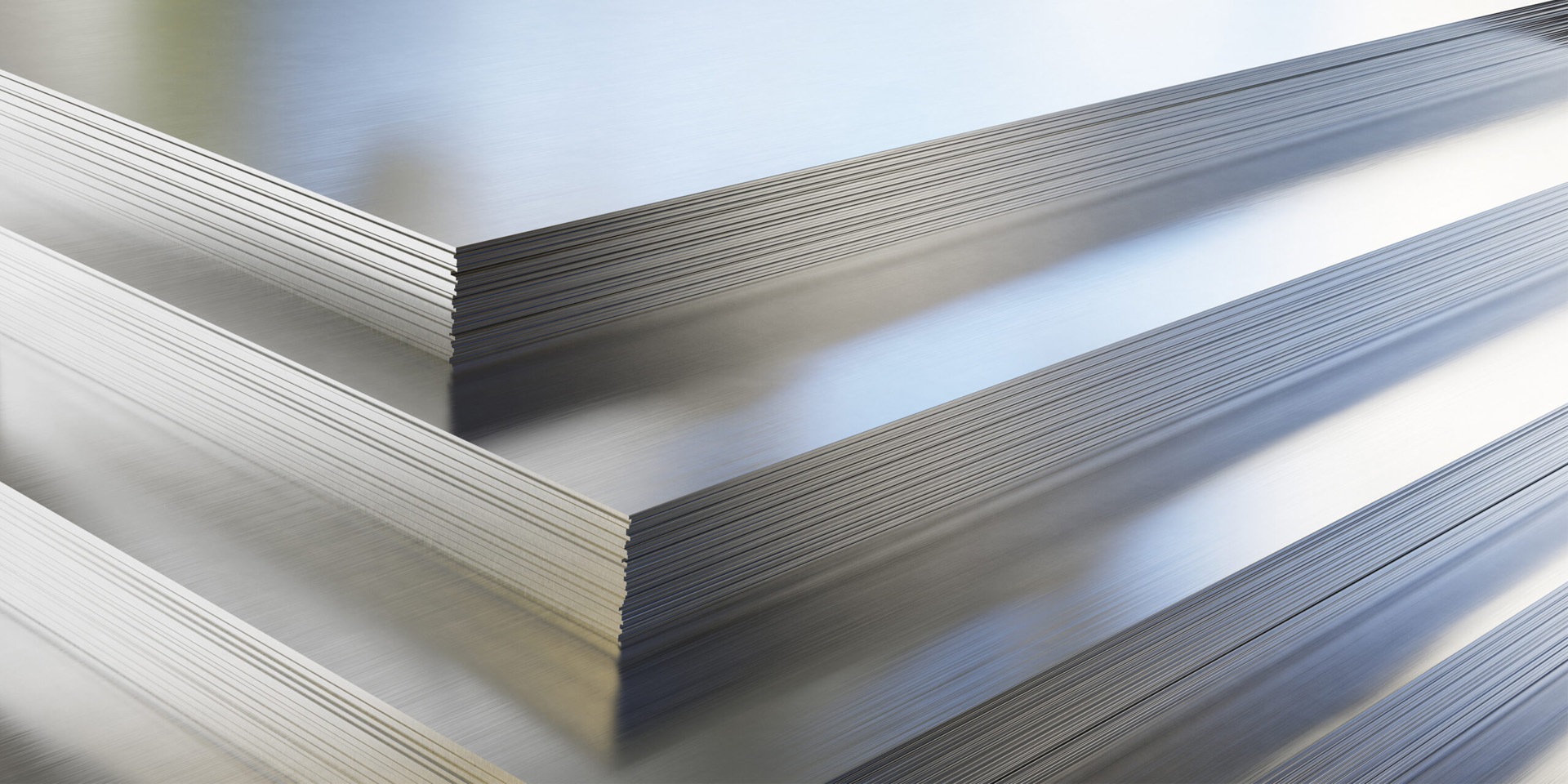

1100 Aluminum Sheet Plate

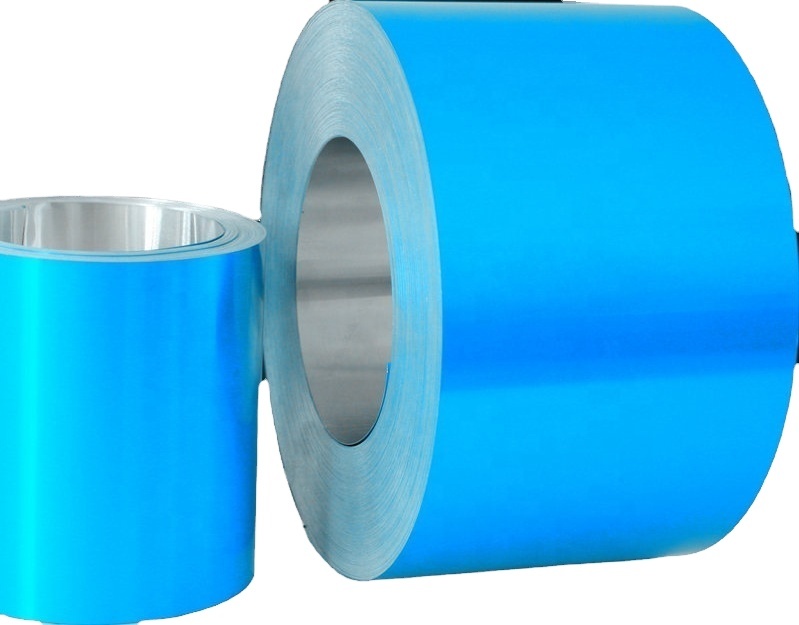

1100 Aluminum Sheet Plate is a kind of pure aluminum sheet product with an aluminum content of not less than 99.00%. It belongs to the 1000 series pure aluminum alloy. As a commonly used pure aluminum material, 1100 aluminum sheet plate has no high strength but outstanding formability, and can be easily cut, bent, stamped, welded, and polished. It is widely used in various fields such as daily necessities, packaging, electronics, construction, and light industry, and is a cost-effective pure aluminum sheet product with a wide range of applications.

MESSAGE

Overview

The 1100 aluminum sheet plate belongs to the industrial pure aluminum series, with an aluminum content of no less than 99.0%. It features excellent ductility, formability, and corrosion resistance. Due to its non-heat-treatable nature, its strength is primarily enhanced through cold working, making it suitable for applications requiring good processability rather than high strength. With a low density (2.7-2.8g/cm³) and superior electrical/thermal conductivity, it is widely used in electronics, architectural decoration, food packaging, and chemical equipment.

Specification

Alloy: 1100

Temper: O, H12, H14, H16, H18, H22, H24, H26, H28, etc

Thickness: 0.1-400mm

Width: 600-4300mm

Length: 600-12000mm

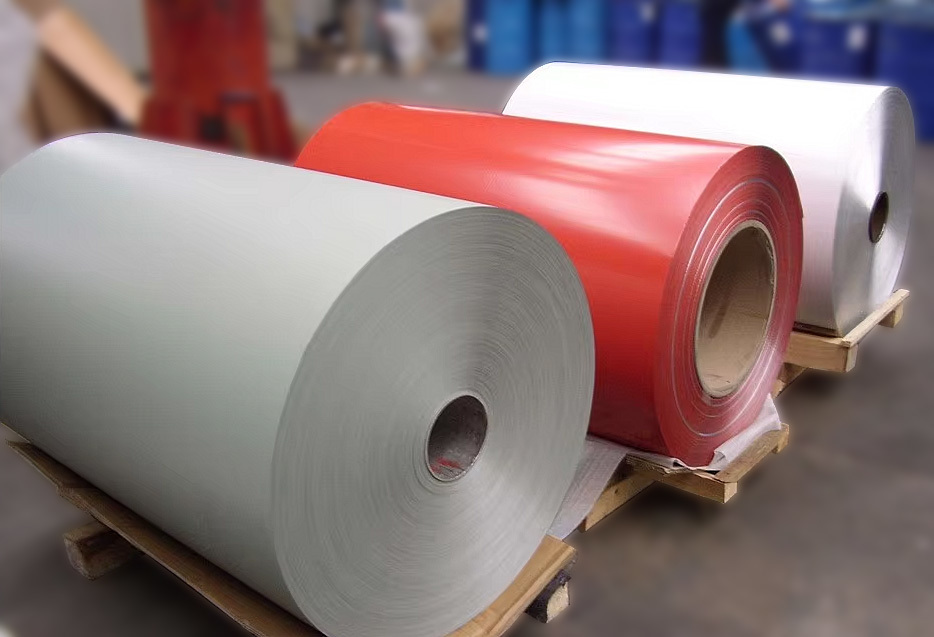

Surface Treatment: Mill Finish, Anodized, Coating

Feature

1.Good Corrosion Resistance: A natural aluminum oxide film is formed on the surface, which can effectively resist the erosion of air, moisture and general weak acids and alkalis. After surface treatment (such as anodizing), the corrosion resistance can be further improved.

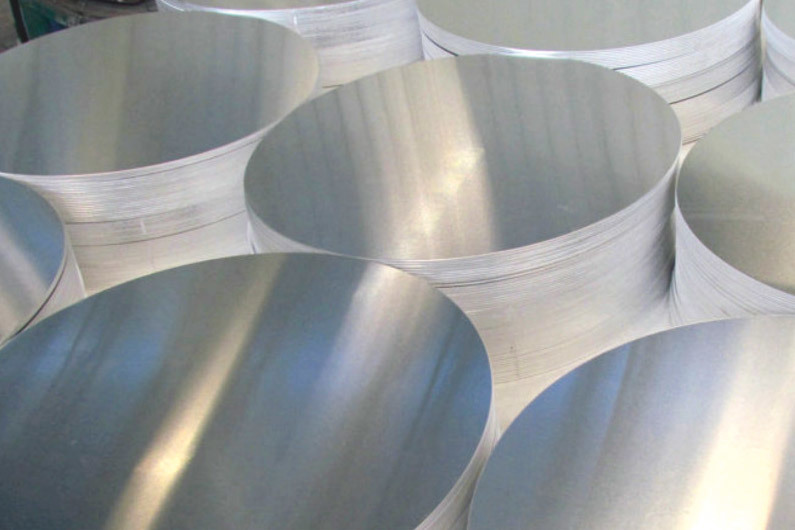

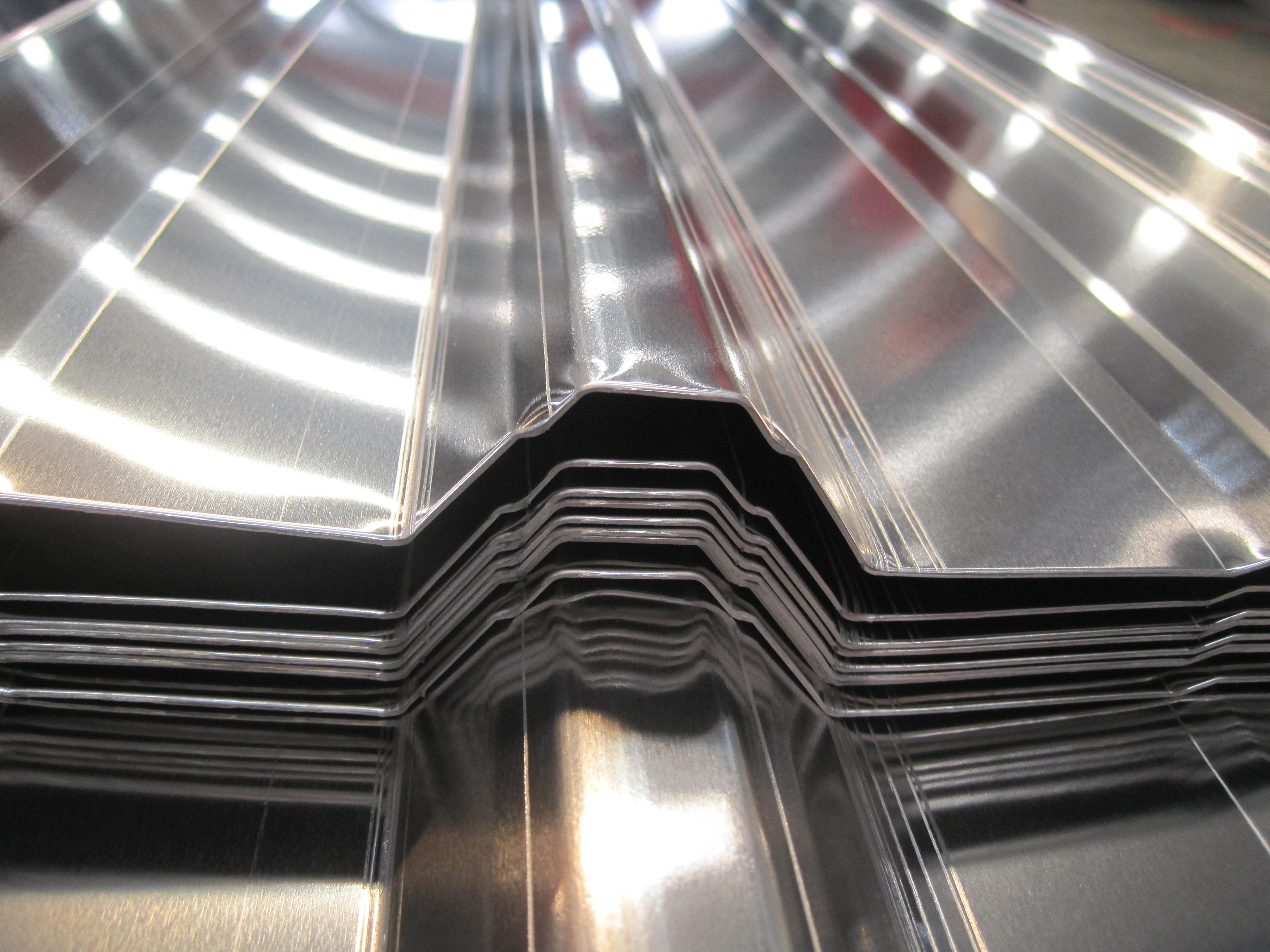

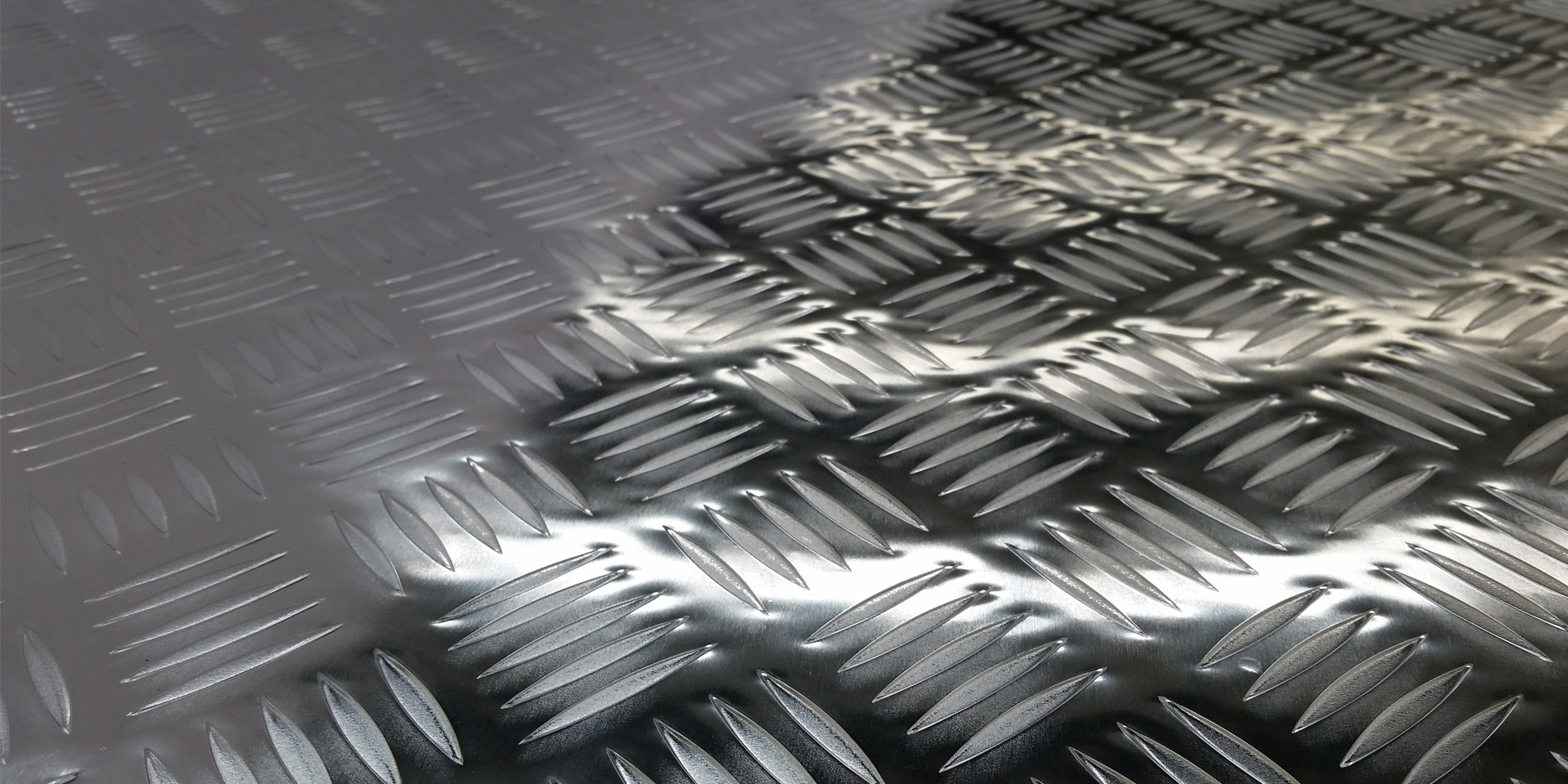

2.Excellent Formability and Processability: It has good ductility and toughness, and can be easily processed by bending, stamping, rolling, welding, polishing and other processes without cracking or deformation. It is suitable for various complex forming and processing requirements.

3.Superior Electrical and Thermal Conductivity: It inherits the excellent electrical and thermal conductivity of pure aluminum, which is better than most alloy aluminum sheets. It is an ideal material for electrical and thermal conduction components.

4.Smooth Surface and Good Aesthetics: After surface finishing, the board surface is smooth, flat, free of defects such as scratches and indentations, and has a natural metallic luster. It can be further processed by coloring and polishing to improve the decorative effect.

5.Cost-Effective: Compared with alloy aluminum sheets, it has the advantages of simple production process and low cost, while meeting the use requirements of most non-high-strength scenarios, with high cost performance and wide applicability.

Application

1100 Aluminum sheet plate is a commonly used grade of aluminum alloy due to its excellent properties. Here are some of the most common products made using 1100 aluminum sheet plate:

1.Food and beverage packaging: Aluminum 1100 sheet is often used in the manufacturing of food and beverage packaging, such as cans and containers, due to its non-toxicity and resistance to corrosion.

2.Heat exchangers: The high thermal conductivity of aluminum 1100 sheet makes it well-suited for use in heat exchangers, which are used in a wide range of industries, including HVAC, automotive, and aerospace.

3.Reflectors and lighting: The high reflectivity of aluminum 1100 sheet makes it a popular choice for use in lighting fixtures and reflectors.

4.Electrical and electronic components: The high conductivity of aluminum 1100 sheet makes it an ideal material for use in electrical and electronic components, such as wires and connectors.

PREV

PREV

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!