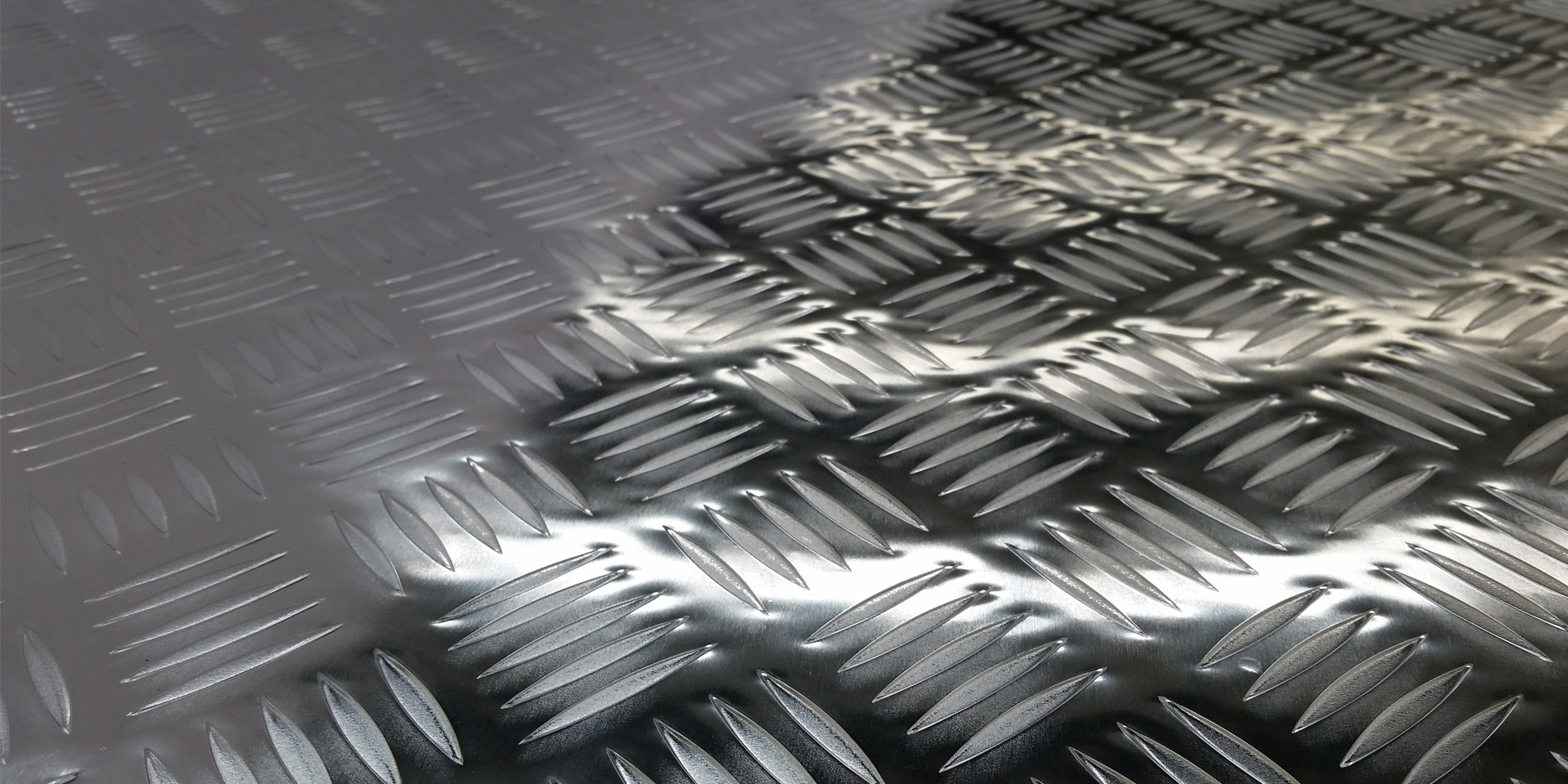

Embossed Aluminium Coil for Pipe Insulation

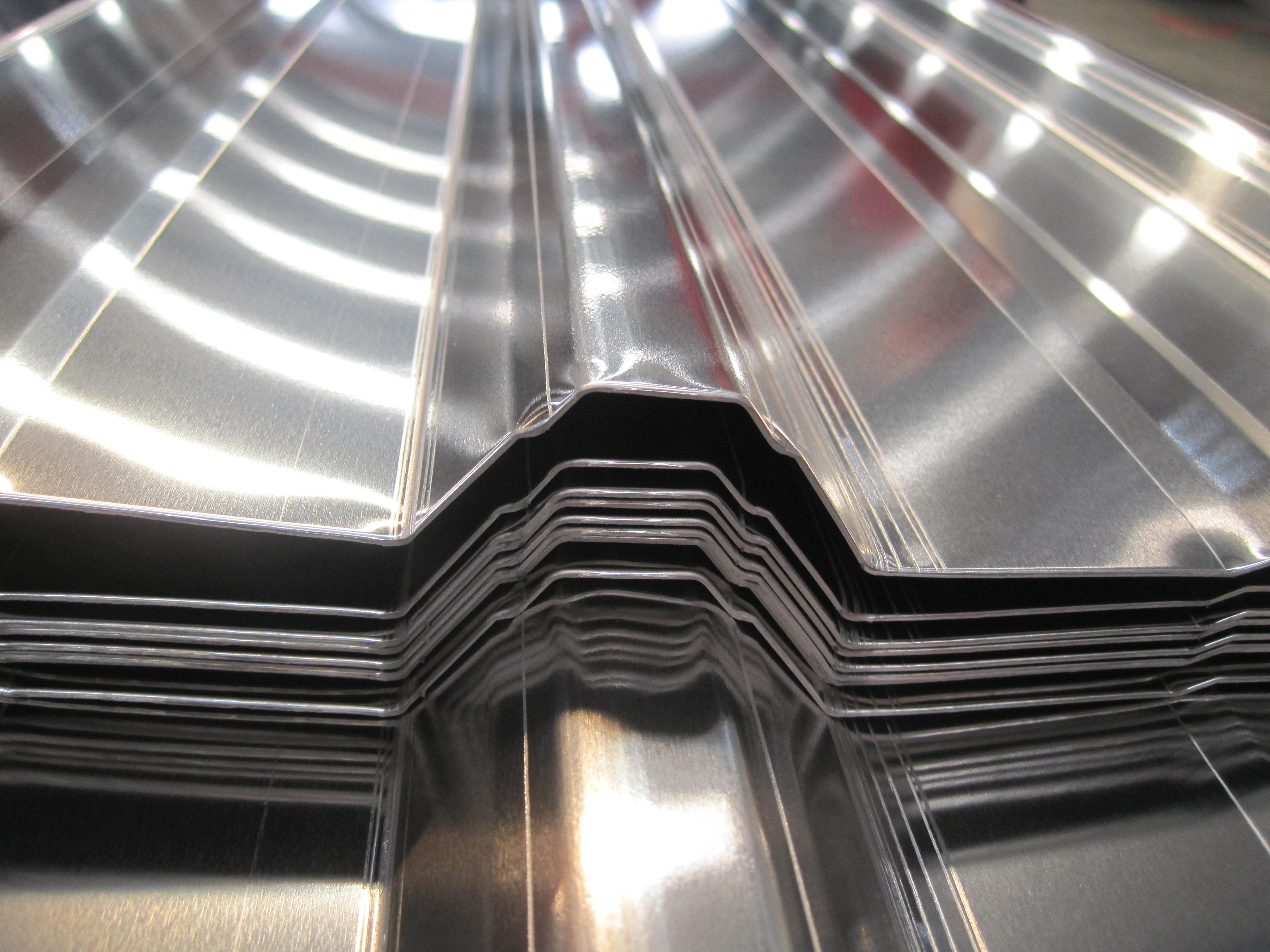

Embossed aluminium coil for pipe insulation is a specialized material designed for thermal insulation and protection of pipelines in industrial and mechanical systems. It is manufactured by processing aluminium sheets with embossed patterns (e.g., orange peel) to enhance surface strength, slip resistance, and thermal performance. The coil is widely used in industries such as oil and gas, petrochemical, HVAC, and power generation to prevent heat loss, corrosion, and physical damage to pipes.

MESSAGE

Overview

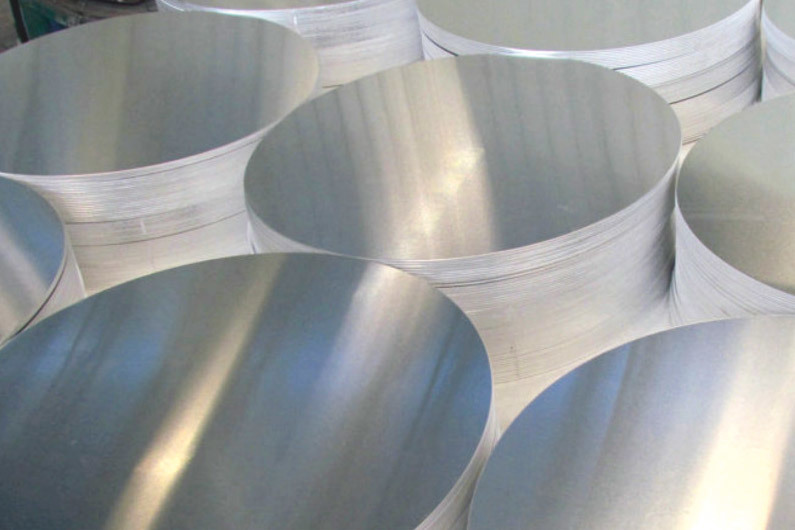

Embossed Aluminium Coil for Pipe Insulation is a professional protective and auxiliary insulation material specially developed for pipeline insulation systems. It takes high-quality aluminum alloy as the base material, and forms regular embossed patterns on the surface through advanced embossing technology, combined with optional surface coating to enhance its protective performance. It is widely used in various industrial, municipal and building pipeline insulation projects, such as heating pipes, air conditioning pipes, chemical pipelines and thermal insulation pipelines.

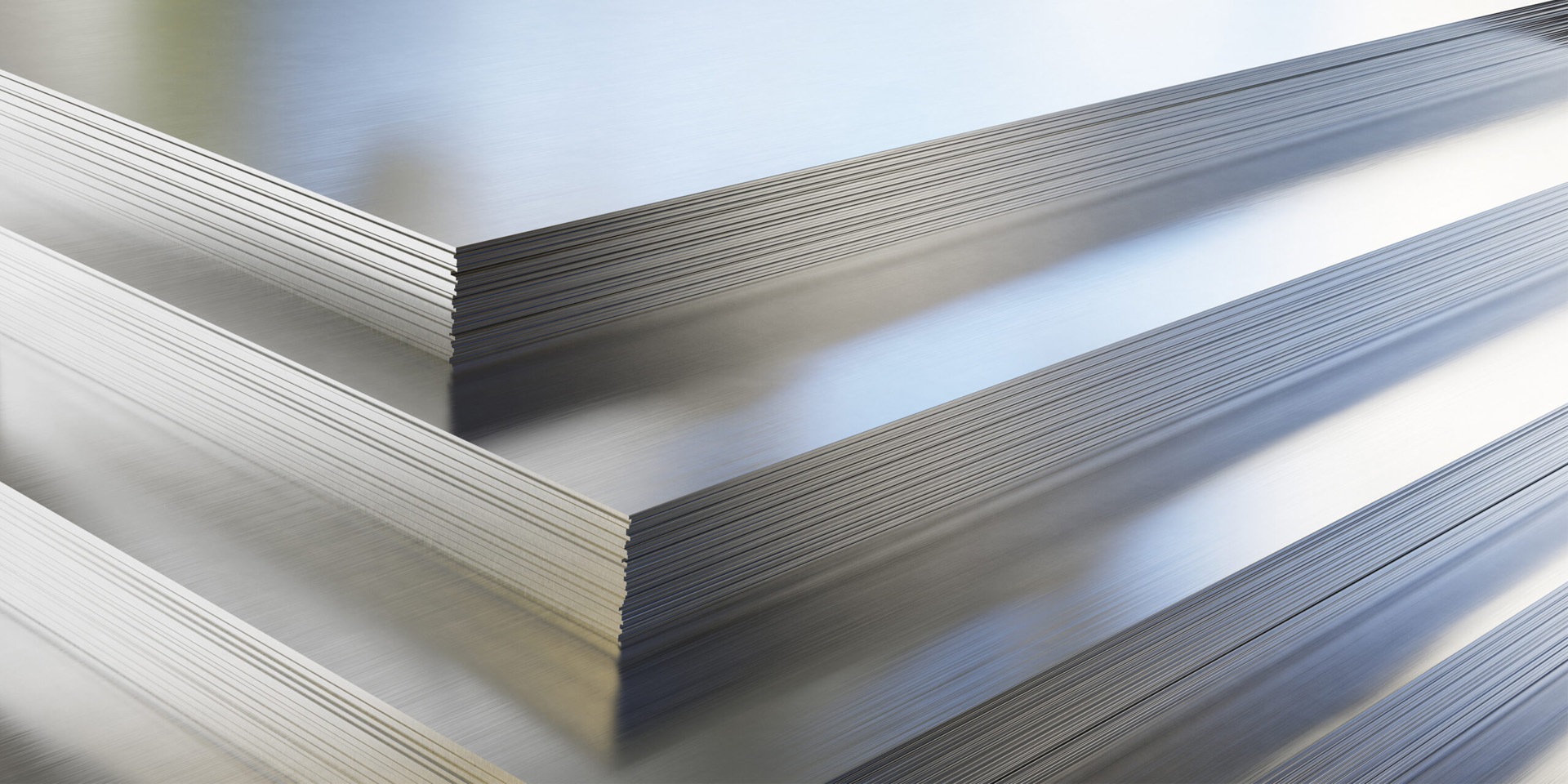

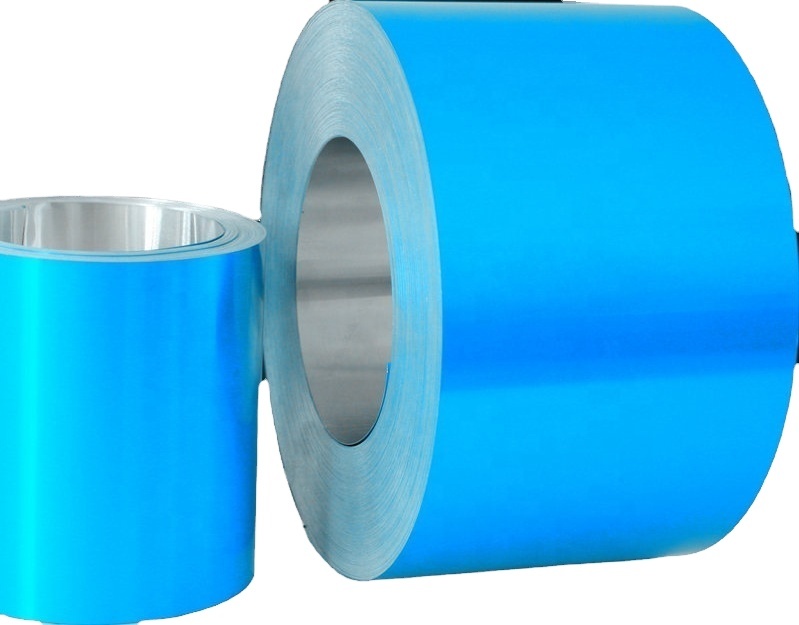

Specification

Alloy: 1060, 3003, 5005, etc

Temper: O, H14, H16, H18, H24, H26, etc

Thickness: 0.2mm–1.5mm

Width: 20mm–1600mm

Embossed Pattern: Diamond, Orange Peel

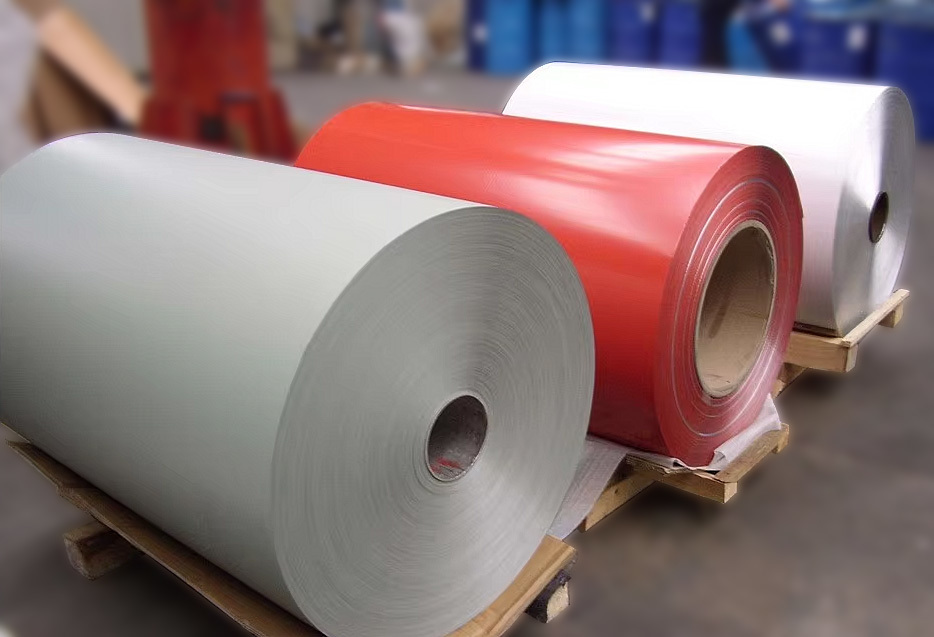

Finish: Plain mill finish or painted

Protective Film: Polysurlyn (PSMB), Kraft, Poly kraft, or Bare

Feature

1.Outstanding Durability & Protective Performance — The embossed pattern greatly enhances the material’s rigidity and impact resistance, effectively protecting the insulation layer from physical damage, foot traffic and equipment collisions, thus prolonging the service life of the entire insulation system.

2.Superior Corrosion Resistance — Aluminum naturally forms a protective oxide film on its surface, which can resist rust and corrosion. This feature is particularly critical for outdoor or humid environments, making the embossed aluminum insulation jacketing a reliable barrier against weather factors and corrosive substances.

3.Improved Thermal Efficiency — By preventing the insulation layer from moisture and damage, the jacketing ensures its stable thermal insulation performance, reducing heat loss or gain, achieving remarkable energy savings and maintaining consistent temperature control in the system.

4.Elegant Aesthetic Appeal — The embossed surface presents a clean, professional and visually pleasing look for insulated pipes and equipment, helping to enhance the overall appearance of the facility.

5.Easy Installation & Maintenance — Thanks to its lightweight property, the aluminum coil is easy to cut and form, simplifying the installation process. After installation, the embossed aluminum insulation jacketing requires little maintenance, usually only regular cleaning.

6.Reliable Fire Safety — Aluminum is a non-combustible material, which adds an extra layer of fire protection to industrial installations, enhancing overall safety.

Application

With its versatile performance and excellent protective features, embossed aluminum coil is ideal for diverse application scenarios across multiple industries:

1.Industrial Plants — Widely applied to insulating pipelines, air ducts and containers that transport hot or cold fluids in factories and manufacturing facilities.

2.HVAC Systems — Offers durable protective effects for air ducts and chilled water pipelines in commercial buildings and large-scale residential complexes.

3.Petrochemical Plants and Refineries — Plays an essential role in protecting the insulation of pipelines and tanks that convey flammable or corrosive chemicals.

4.Power Generation Plants — Utilized in power plants for steam pipelines, turbine components and other high-temperature application scenarios.

5.Food and Beverage Processing Industry — Protects the insulation of pipelines and equipment, helping to maintain hygienic conditions and stable temperature control.

6.Pharmaceutical Industry — Ensures the integrity of insulation in environments that demand strict temperature stability and cleanliness standards.

7.Marine Applications — Applied on ships and offshore platforms, benefiting from its excellent corrosion resistance in saltwater environments.

8.Cryogenic Applications — Safeguards the insulation of equipment handling extremely low temperatures, preventing frost accumulation and moisture intrusion.

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!