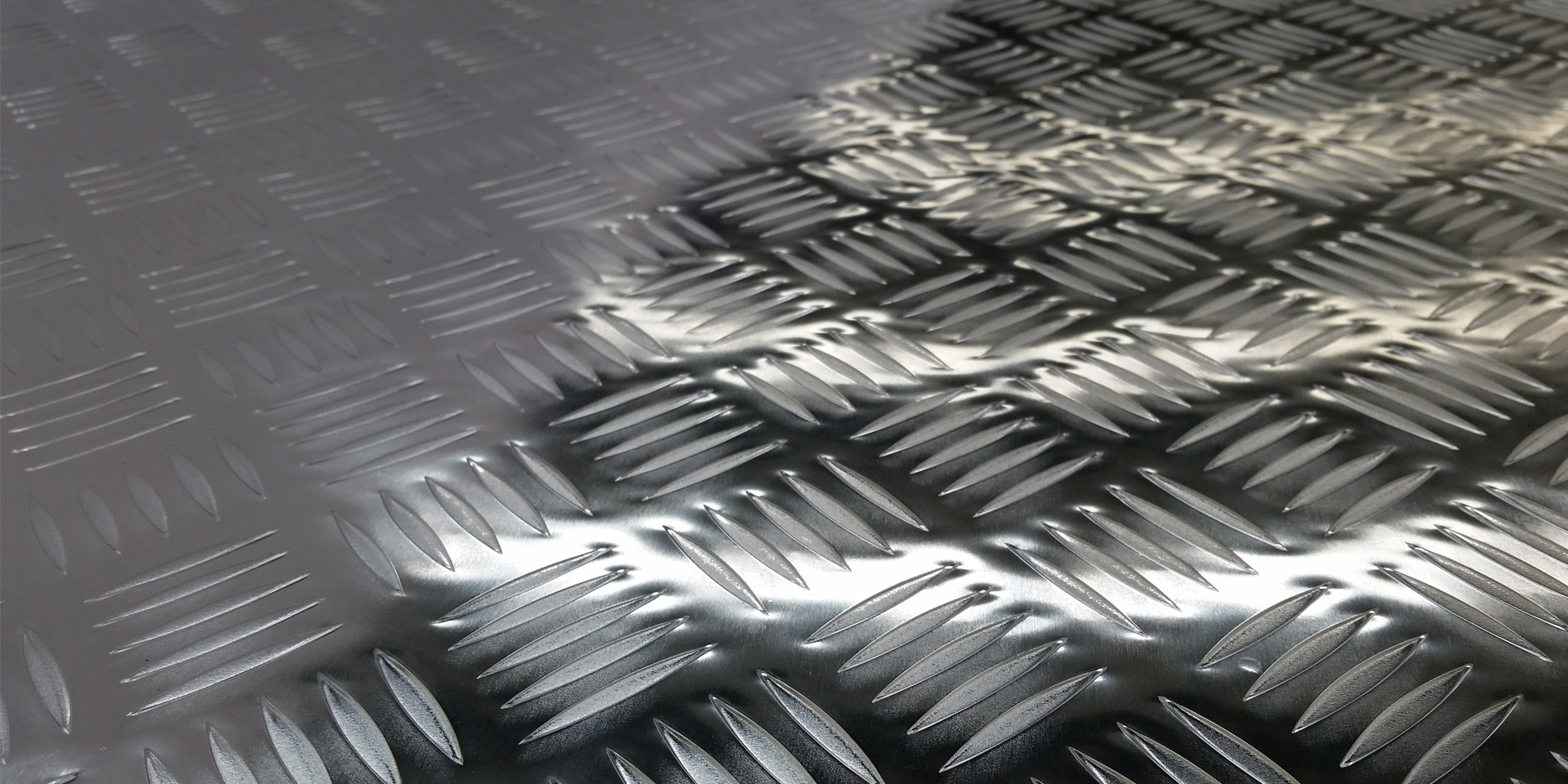

5 Bars Aluminum Tread Plate

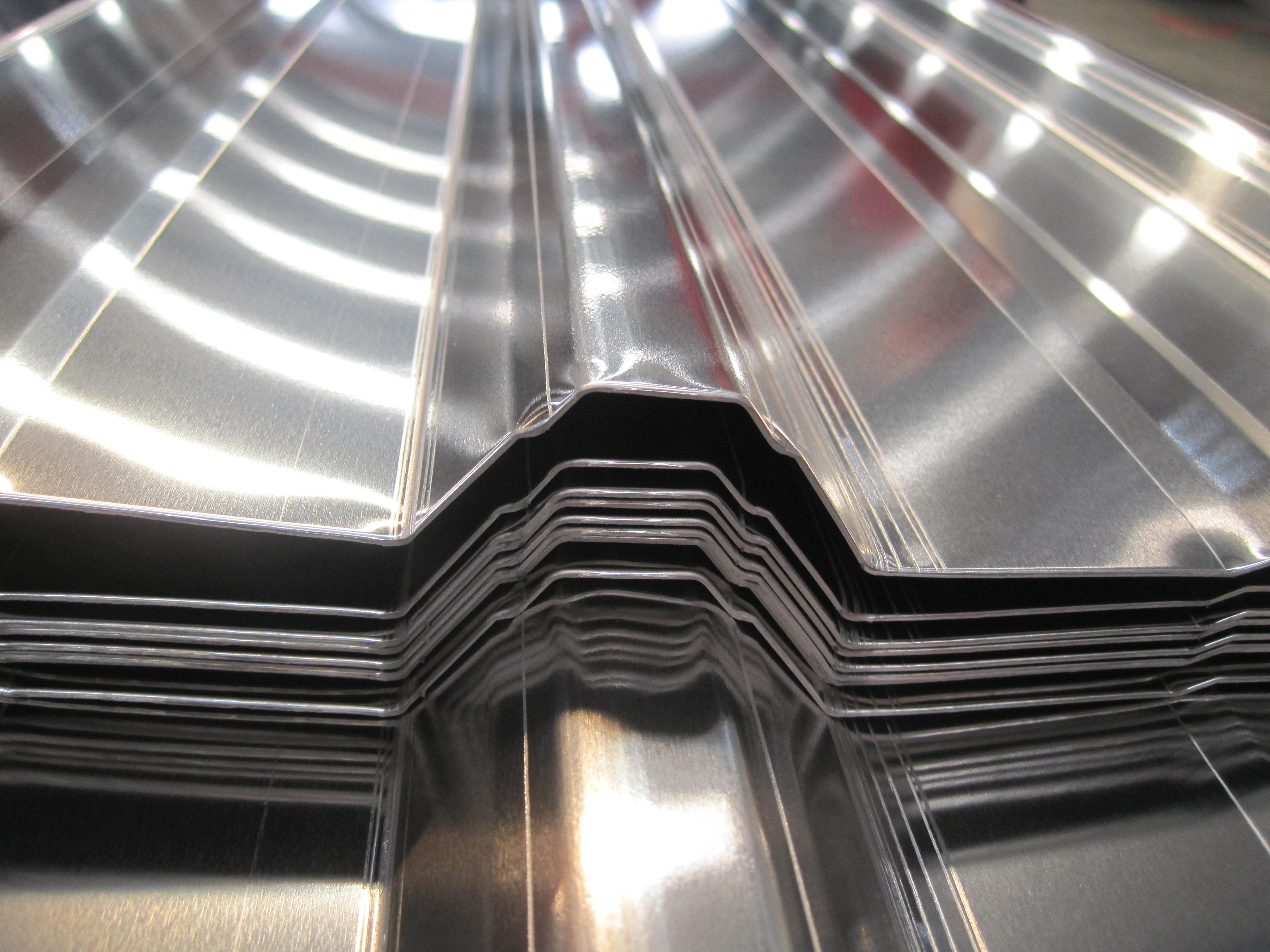

The 5 bars aluminum tread plate is a deep-processed product featuring five parallel raised stripes on the aluminum surface, formed through pressure processing. As a type of aluminum checkered plate, its stripes are arranged at a 60-80° angle, creating a unique anti-slip texture that combines aesthetics with functionality.

MESSAGE

Overview

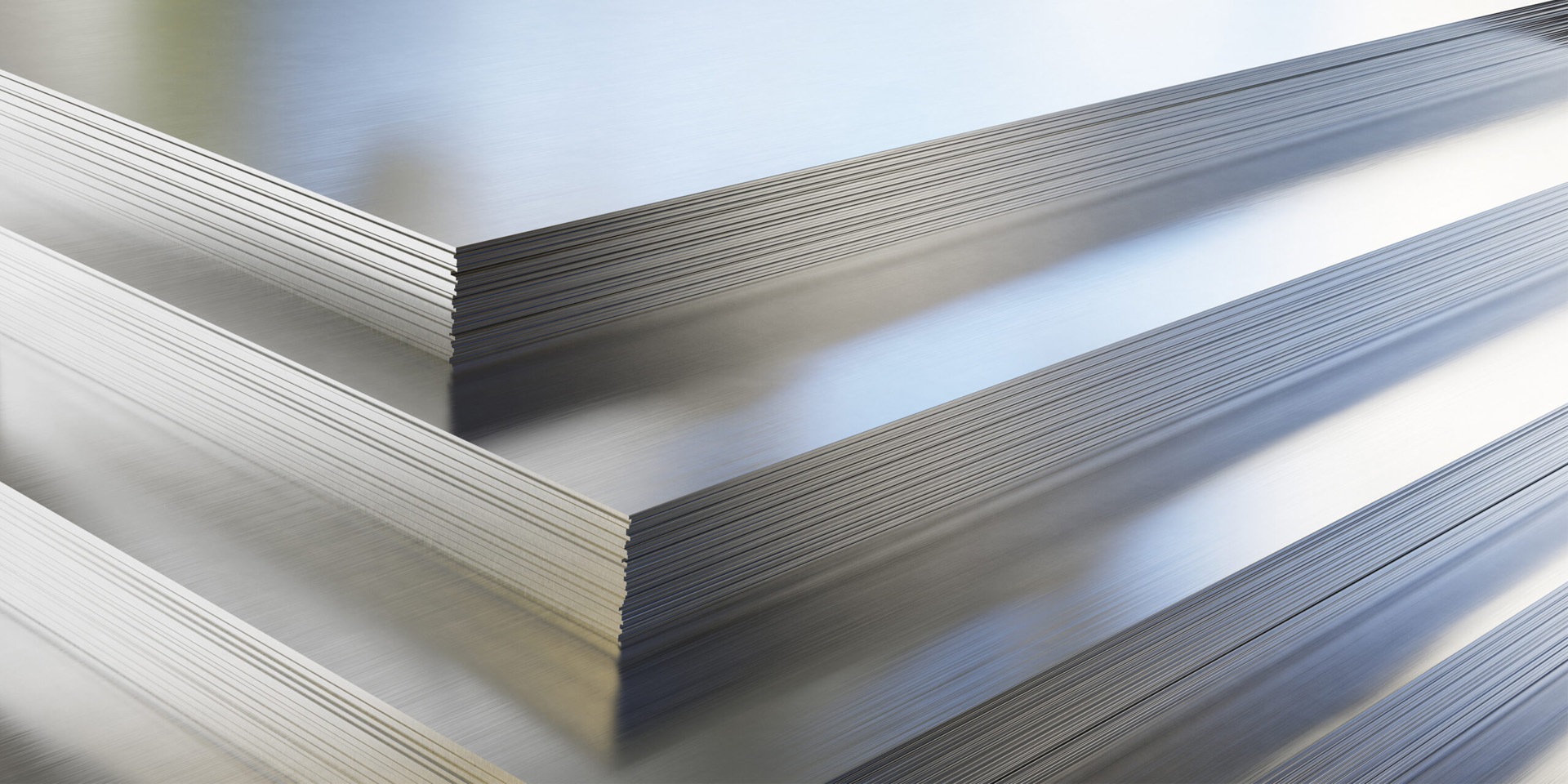

5 bars aluminum tread plate, is a type of tread aluminum sheet characterized by five parallel raised ribs (bars) on its surface, with smooth gaps between the ribs. This pattern is designed to balance anti-slip performance, structural strength, and ease of processing. Commonly made from 1000 series (pure aluminum), 3000 series (Al-Mn alloy), or 5000 series (Al-Mg alloy) aluminum, it offers a favorable strength-to-weight ratio and corrosion resistance. Thickness typically ranges from 1mm to 6mm, making it suitable for both light and medium-load applications across industries.

Common Alloys

1000 Series: 1050, 1060, 1100 (pure aluminum, strong corrosion resistance, low cost).

3000 Series: 3003, 3105 (manganese alloy, higher strength than pure aluminum, rust-resistant).

5000 Series: 5052, 5083, 5754 (aluminum-magnesium alloy, high strength, seawater corrosion-resistant).

6000 Series: 6061 (aluminum-magnesium-silicon alloy, heat-treatable for enhanced properties).

| Item | 5 Bars Aluminum Tread Plate |

| Alloy | 1100,1050,1060,3003,3105,5052,5754,5083,5086,6061,6063,6082 |

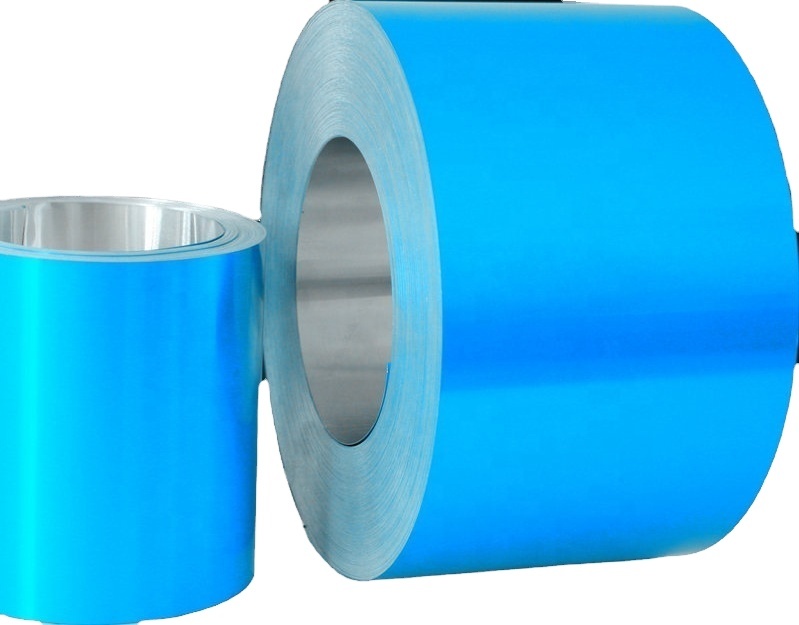

| Temper | HO,H12,H14,H16,H22,H24,H26,H32, H36,etc |

| Thickness | 1mm-6mm |

| Width | 1000mm-2200mm |

| Length | 1000mm-6000mm |

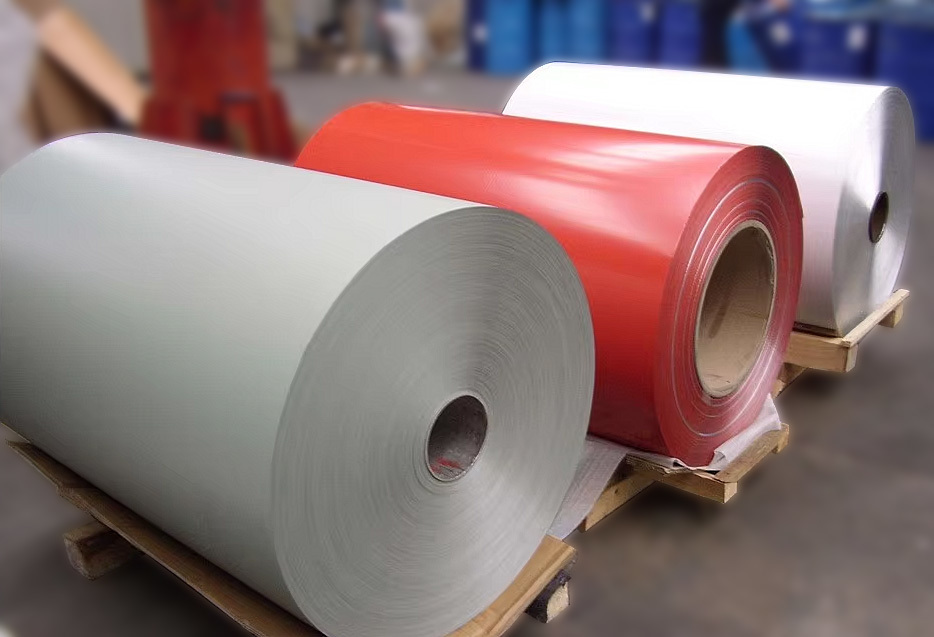

| Surface | Mirror Finish 5 Bars,Plain 5 Bars |

| Pattern | Small/Big 5 bars |

Feature

1.Superior Anti-Slip Performance

The five-bar texture significantly enhances surface friction, making it ideal for wet, oily, or high-load environments, outperforming two-bar or diamond patterns in slip resistance.

2.High Strength-to-Weight Ratio

Aluminum-magnesium alloys (e.g., 5052, 5083) offer high specific strength, weighing only 1/3 of steel, making them ideal for weight-sensitive yet load-bearing applications.

3.Corrosion Resistance

The natural oxide layer on 5000 series alloys resists seawater, acids, and alkalis, making them suitable for harsh marine and chemical environments.

4.Excellent Processability

It can be cold-rolled, hot-rolled, stamped, or bent, with customizable thickness (1-6mm), width (1000-2200mm), and length.

5.Aesthetic Appeal & Durability

Surfaces can be matte, glossy, anodized, or painted, ensuring long-term durability without deformation or fading.

Application

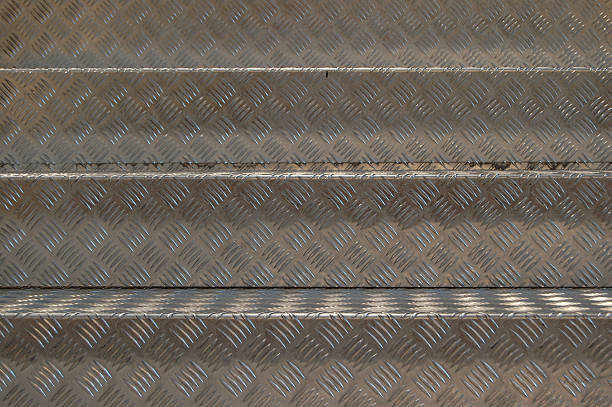

1.Transportation: Vehicle steps, bus floors, truck beds, ship decks, subway stairs, aircraft cabin floors.

2.Architecture: Curtain walls, ceilings, non-slip corridors, stair treads, decorative panels.

3.Industry: Cold storage floors, grain storage ventilation, explosion-proof enclosures, machinery platforms, automation equipment bases.

4.Special Environments: Offshore platforms, chemical plants, fire truck equipment areas.

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!