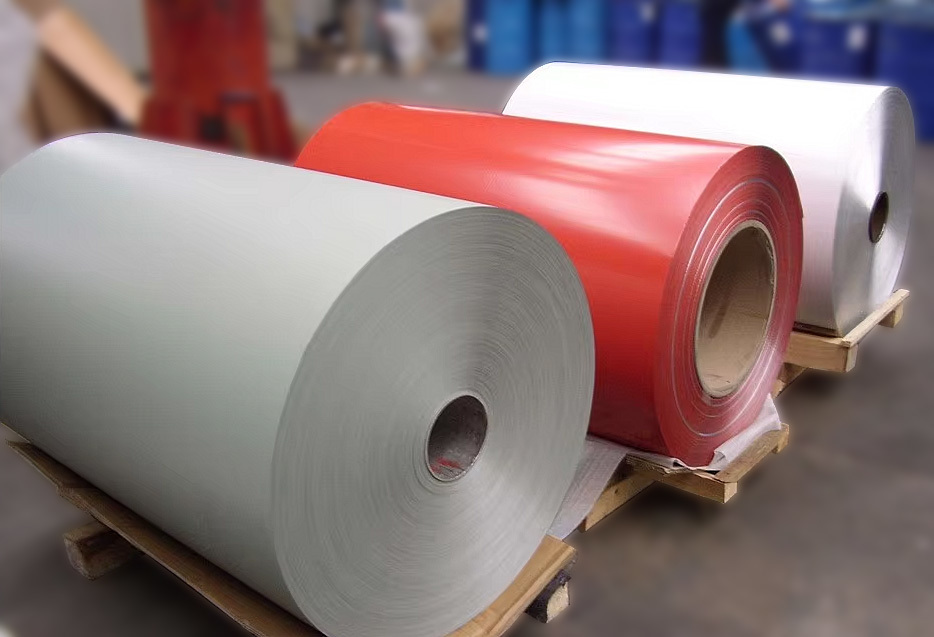

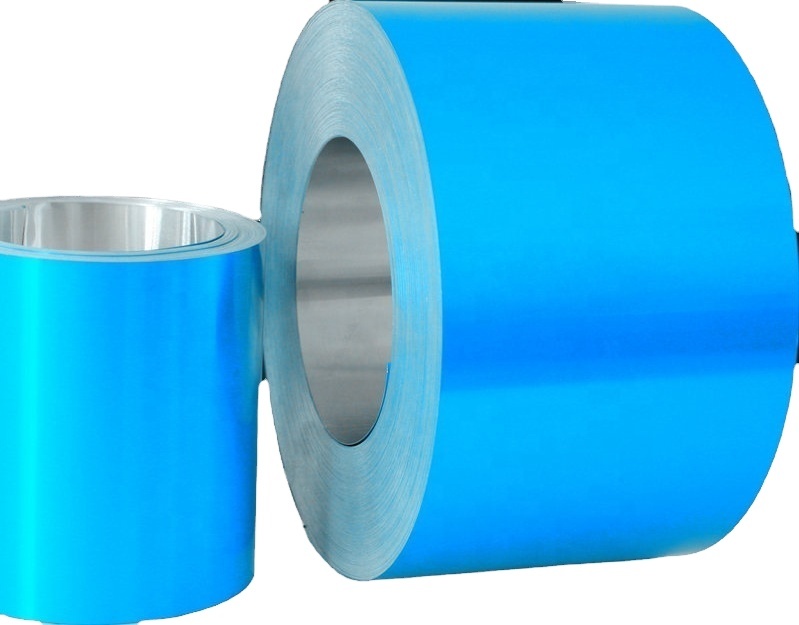

3003 Aluminum Coil

3003 aluminum coil is an aluminum alloy with manganese as the main alloying element, which cannot be strengthened by heat treatment. High plasticity, good welding performance, higher strength than 1-series pure aluminum, stronger corrosion resistance, similar to 1-series aluminum alloy. Because 3003 aluminum coil has impact resistance and is not easy to break and leak, it can be used as a better material for power battery shell materials. In daily life, our common wine bottle caps, beverage bottle caps, cosmetic caps, etc. can be made of 3003 aluminum coils.

MESSAGE

Overview

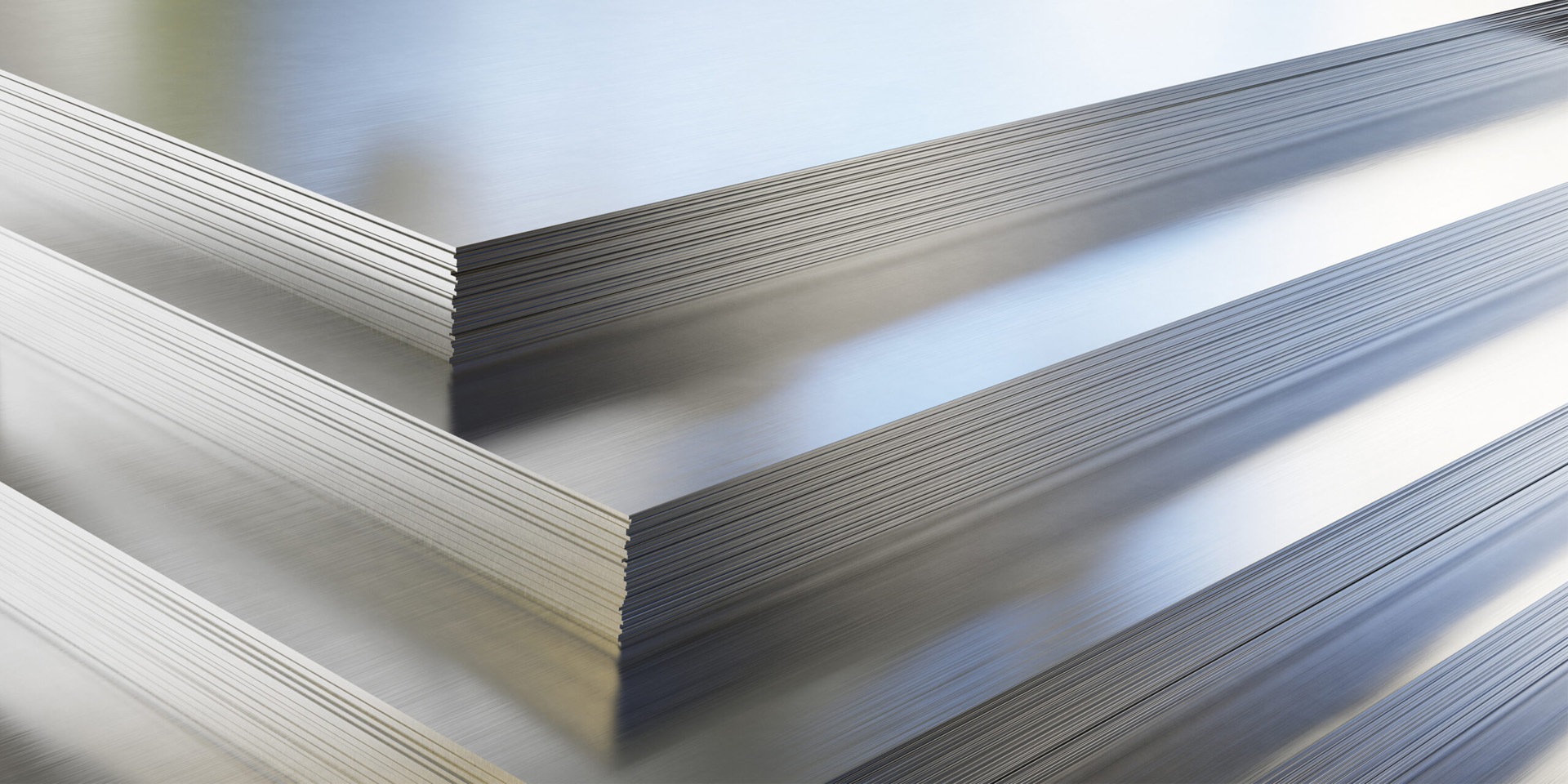

3003 aluminum coil is an alloy product from the 3000 series aluminum-manganese alloy family. It is formed by adding manganese (Mn) as the main alloying element to pure aluminum, typically containing 1.0-1.5% manganese. This alloy strikes a balance between strength, corrosion resistance, and workability, making it one of the most widely used non-heat-treatable aluminum alloys in industrial applications.

Specification

Alloy: 3003 aluminum coil

Temper: O,H14,H16,H18,H22,H24,H26,H28

Thickness: 0.2mm-8mm

Width: Max 2650mm

Feature

1.Corrosion Resistance

Excellent resistance to atmospheric, freshwater, seawater, food, organic acids, gasoline, and neutral inorganic salt solutions.

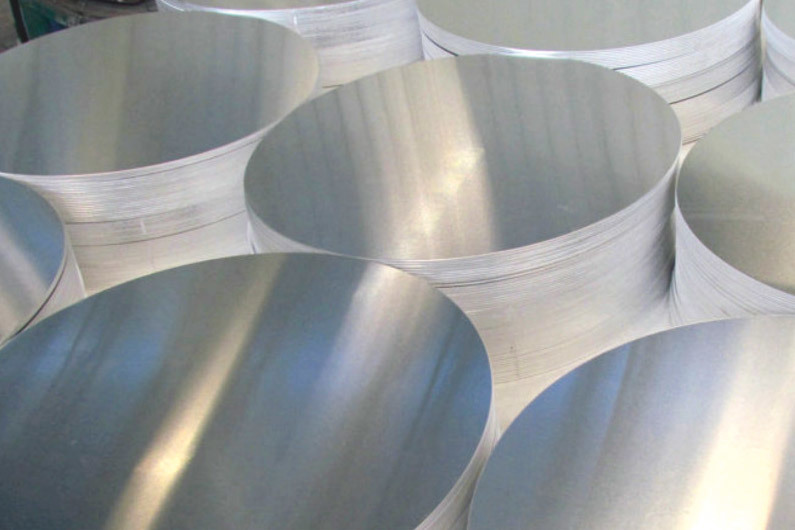

2.Formability & Workability

High plasticity in annealed state; retains good plasticity during semi-cold work hardening.

3.Weldability

Compatible with TIG, MIG, and spot welding without significant post-weld strength loss.

4.Strength

Approximately 20% stronger than 1100-series pure aluminum while maintaining low density (~2.73 g/cm³).

5.Non-Heat Treatable

Strengthened via cold working only (e.g., rolling, drawing).

6.Surface Finish

Supports anodizing, painting, and coating for enhanced aesthetics or corrosion protection.

7.Impact Resistance

Resistant to breakage and leakage under impact, making it suitable for pressure vessels and battery shells.

Common uses

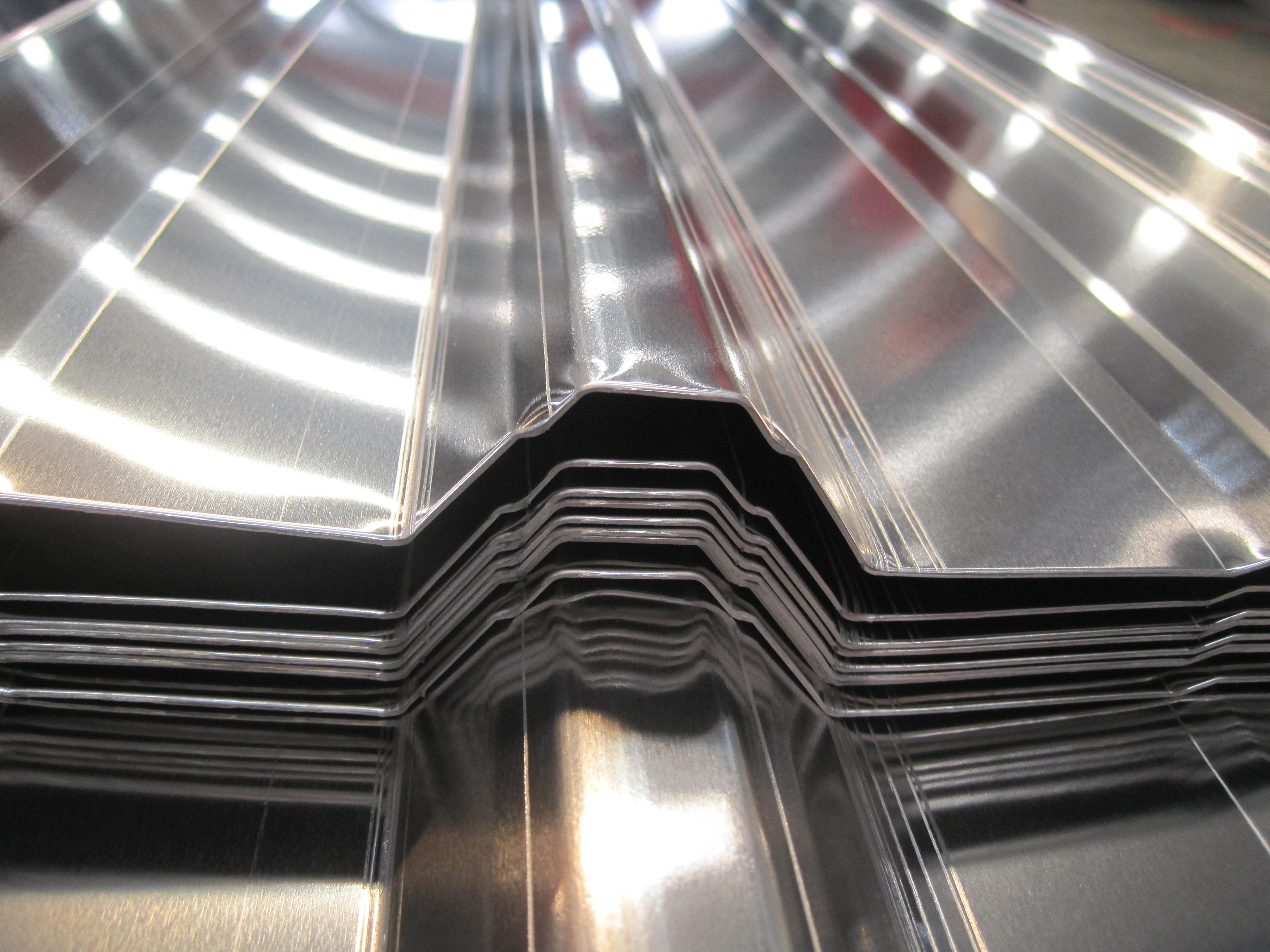

1.Construction:Used for roofing, curtain walls, gutters, shutters, and other architectural decorative components, leveraging its corrosion resistance and aesthetics.

2.Packaging:Manufacturing food cans, pharmaceutical packaging foils, beverage bottle caps, etc., meeting hygiene standards with good formability.

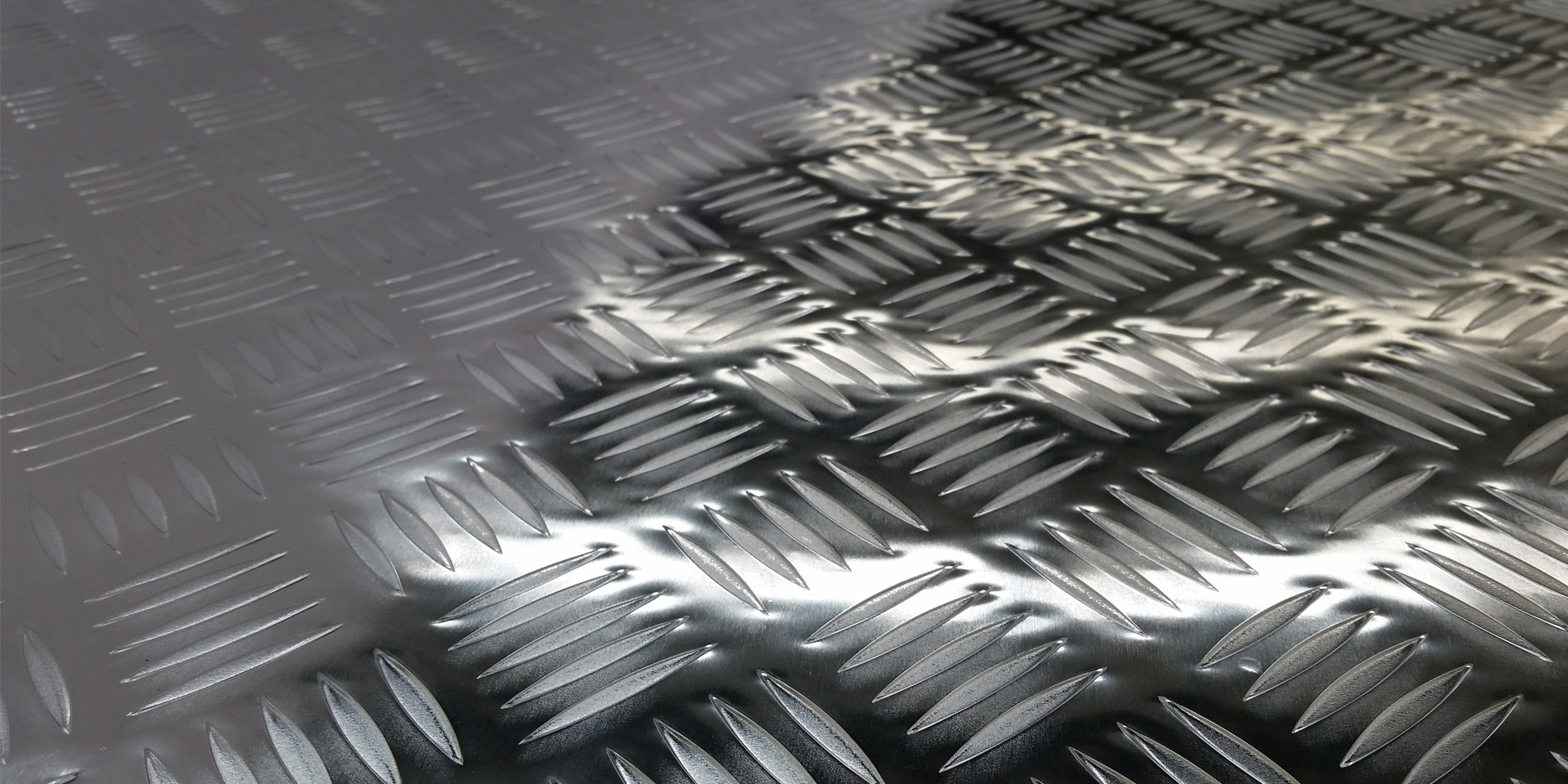

3.Transportation:Automotive fuel tanks, radiators, body panels, truck floors, and lightweight structural components for trains and ships.

4.Electronics & Electrical:Electrical enclosures, cable trays, heat sinks, utilizing its conductivity and heat dissipation.

5.Daily Utilities:Kitchenware, furniture decorative strips, luggage frames, balancing strength and corrosion resistance.

PREV

NEXT

PREV

NEXT

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!