Aluminum for Transformer

Aluminum for transformers are utilized in transformers within the field of electrical engineering and power distribution. This includes applications in power plants and substations, local distribution networks, wind power facilities, industrial plants, as well as in power adaptors for electronic devices.

MESSAGE

Overview

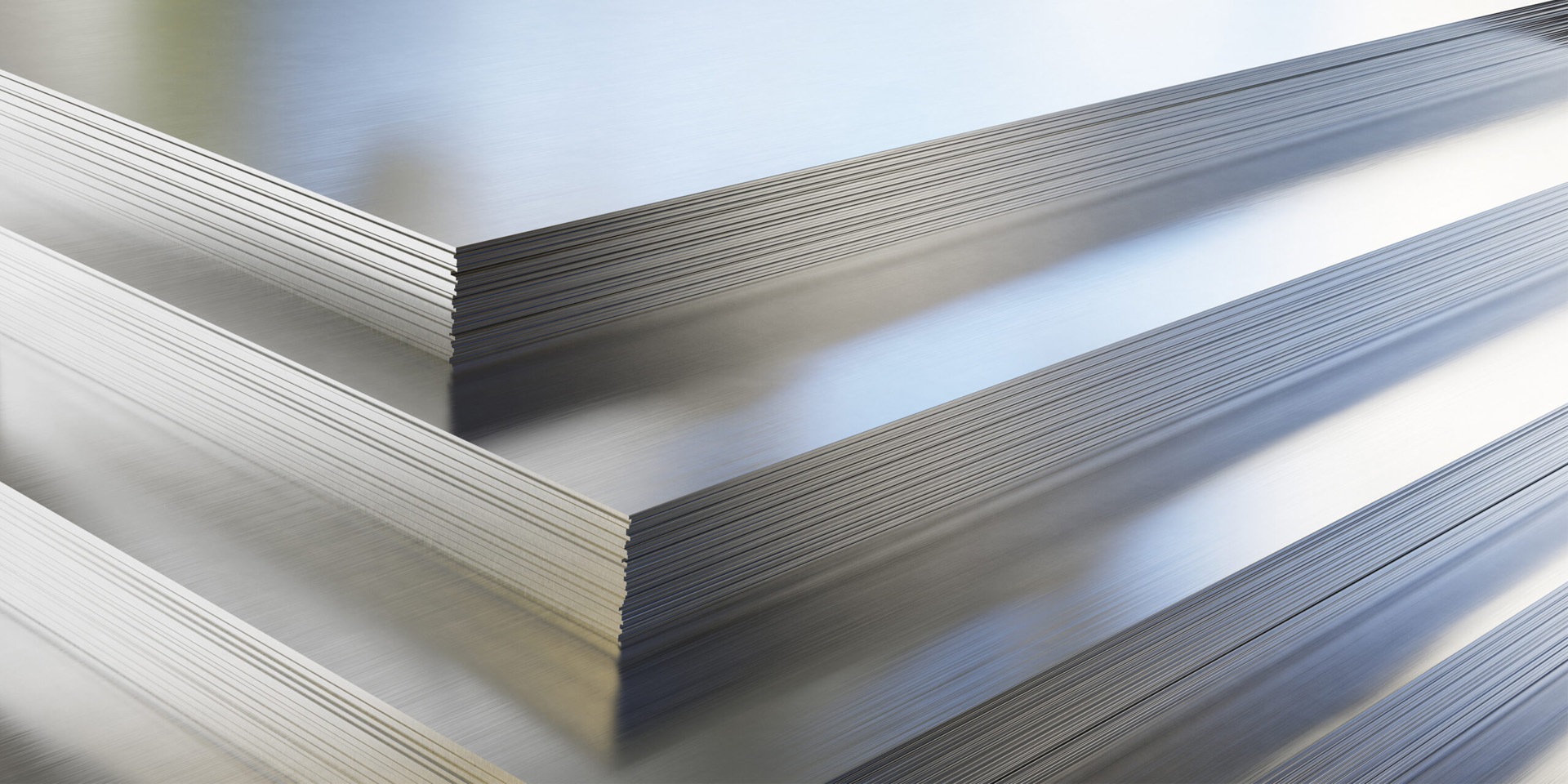

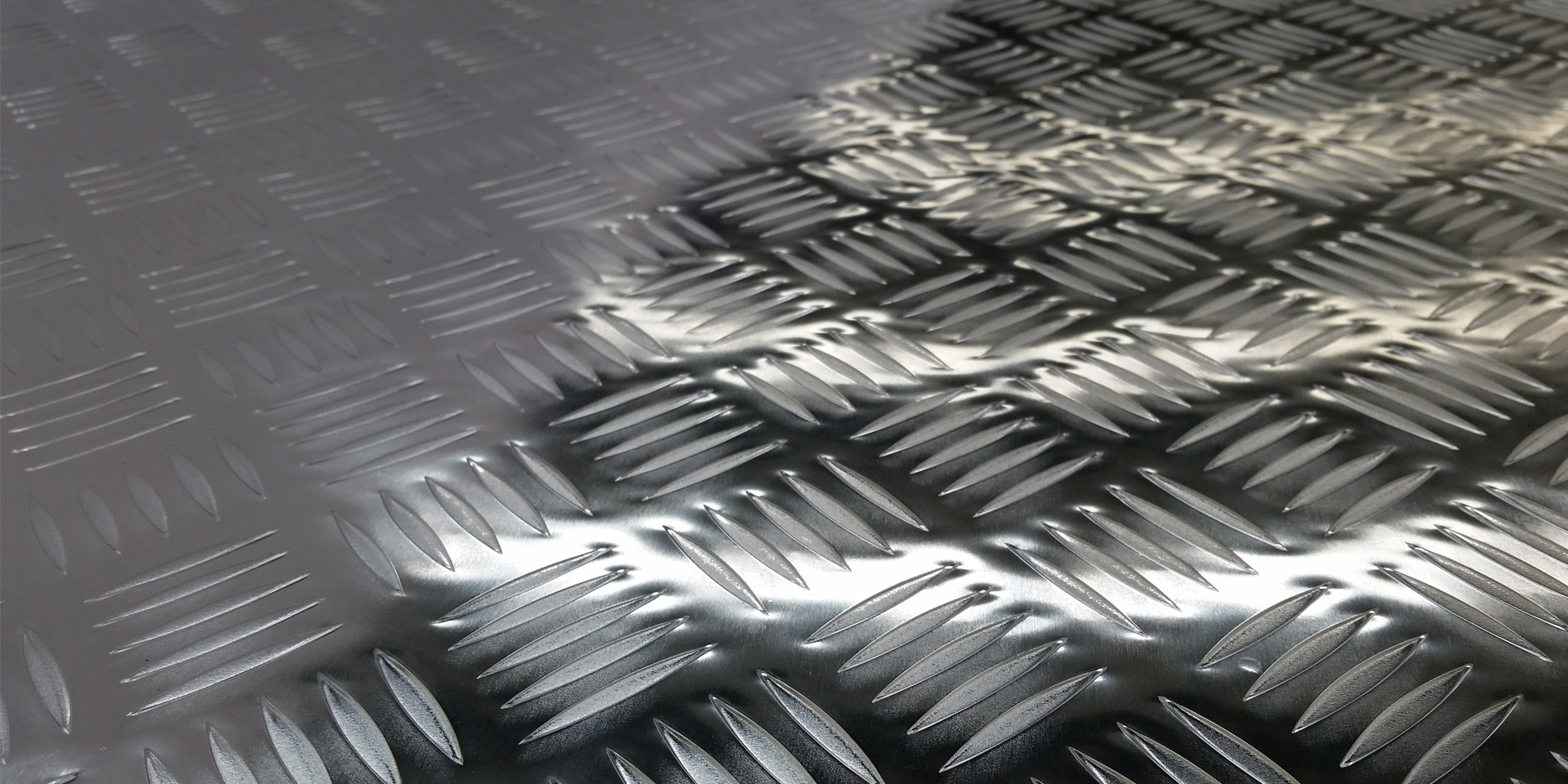

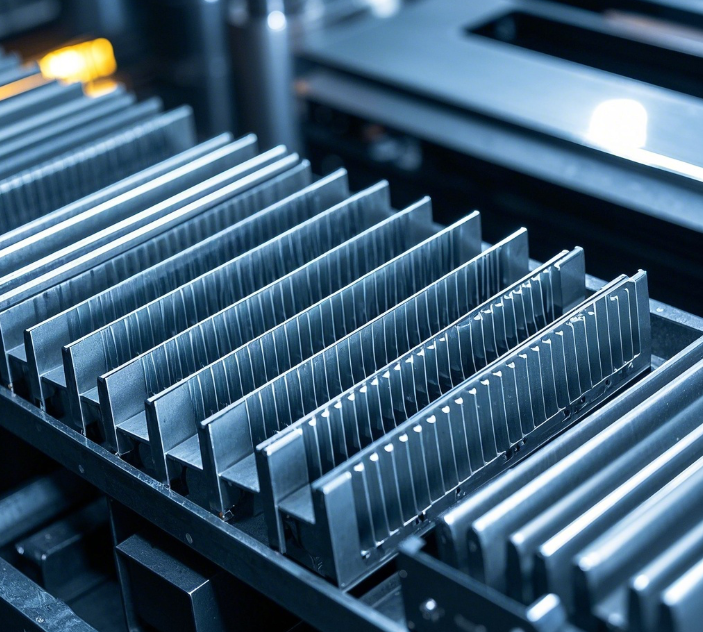

Aluminium, as the core material for transformers, is widely used for conductive windings, core structures, heat sinks and enclosures. Its lightweight and low-cost characteristics significantly reduce equipment weight and manufacturing costs, while maintaining excellent conductivity and corrosion resistance.

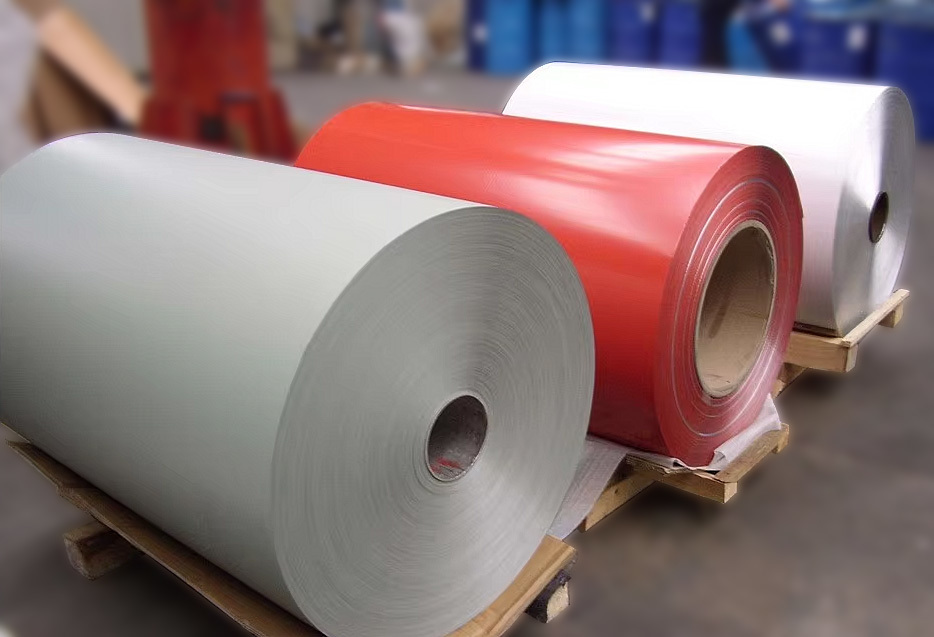

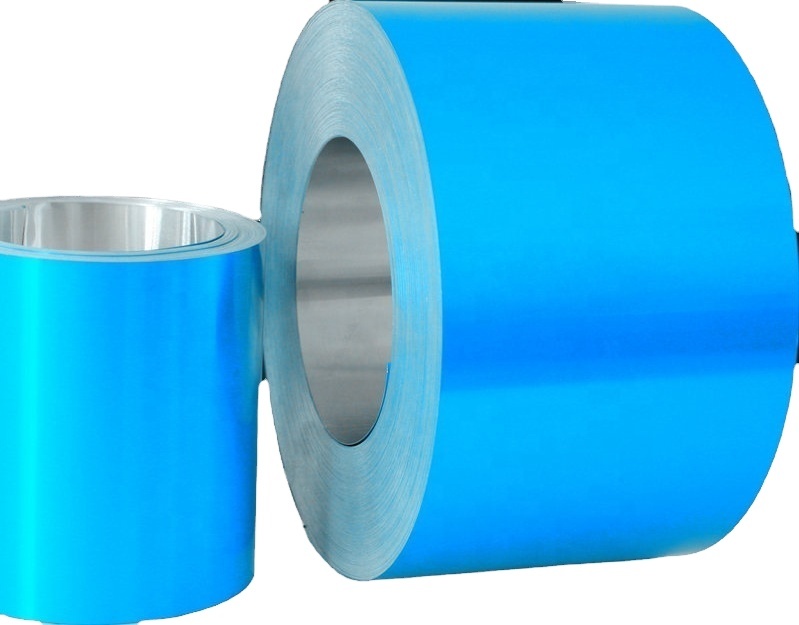

Alloy | 1100,1050,1060,1080,1350 |

Temper | HO,H12,H14,H16,H18 |

Thickness | 0.2mm-7mm |

Max Width | 2650mm |

Feature

1.Balance of conductivity and economy:Aluminium's slightly lower conductivity than copper, but at only about 1/3 the cost of copper, and its low density (about 1/3 that of copper), significantly reduces transformer weight and manufacturing costs, making it particularly suitable for weight-sensitive scenarios.

2.Corrosion resistance and stability:Aluminium surface is easy to form dense alumina film, can effectively resist moisture, oxidation and other environmental erosion, extend the service life of the transformer, especially suitable for outdoor or corrosive working conditions.

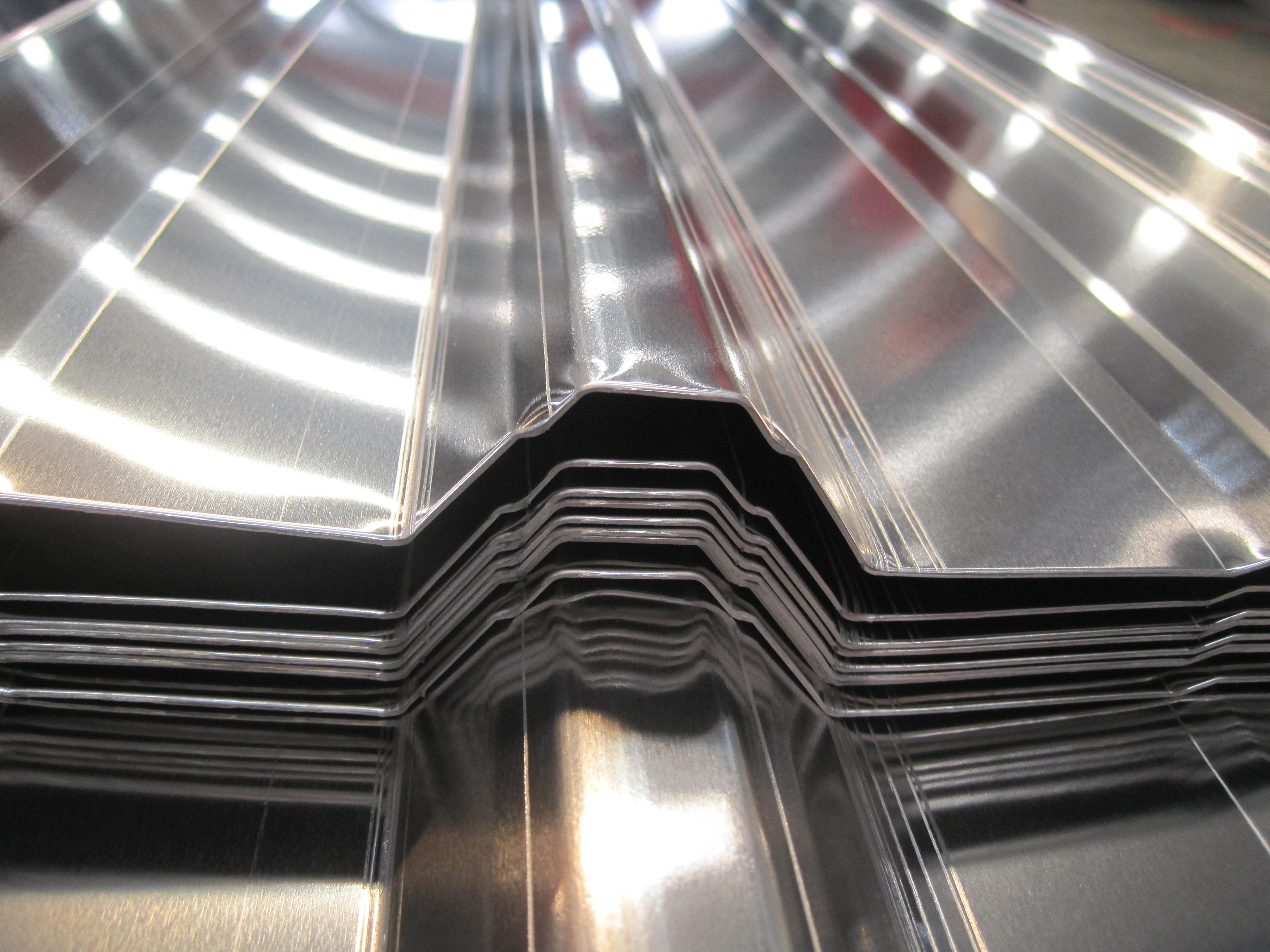

3.Mechanical performance suitability:Aluminium has good ductility and flexibility, easy to process into winding wire, while its lower density can reduce the overall weight of the transformer, enhance the convenience of transport and installation.

Common uses

To make protective and supporting parts such as resistance-winding materials, radiators, heat sinks, cooling pipes, housings, and brackets.

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!