20

2025

-

05

A Full Analysis of Different Aluminium Types and Their Functional Applications

Author:

Introduce the types of aluminium and their diverse applications.

Aluminium is an incredibly versatile material, renowned for its ability to endure significant wear and tear and its capacity for near-infinite recycling. Nevertheless, it comes in various types, each tailored for specific applications, which can sometimes make choosing the right one for your needs a bit challenging. But fear not, we're here to simplify things for you.

In this blog post, we'll delve into the different aluminium grades and their applications. But first, let's understand how aluminium grades are classified.

Each aluminium grade is distinguished by its primary alloying element and is assigned a four-digit number. The first digit indicates the element, while the subsequent digits denote either the minimum aluminium content or specific modifications to the alloy, depending on the series.

This classification system is known as the International Alloy Designation System.

1000 Series Aluminium

Features:

Less strong compared to some other grades.

Well-suited for processes like spinning, welding, or hard forming.

High corrosion resistance.

Good thermal and electrical conductivity.

Applications: Commonly used in food processing, packaging, and electrical transmission.

2000 Series Aluminium – Copper Alloys

With copper as its primary element, 2000 series aluminium is the metal of choice for many high-tolerance industries.

Features:

Lower corrosion resistance relative to other alloys, but can be improved via coating/treatment.

Easy to machine/work with.

Impressive strength-to-weight ratio.

Applications: Common in aerospace and similar industries.

3000 Series Aluminium – Manganese Alloys

3000 series aluminium is one of the most versatile alloys, with manganese as its base metal, and is used in a wide range of products.

Features:

Well-suited for general applications.

Good corrosion resistance.

Highly workable and easily welded.

Moderate strength compared to other alloys.

High-quality surface finish.

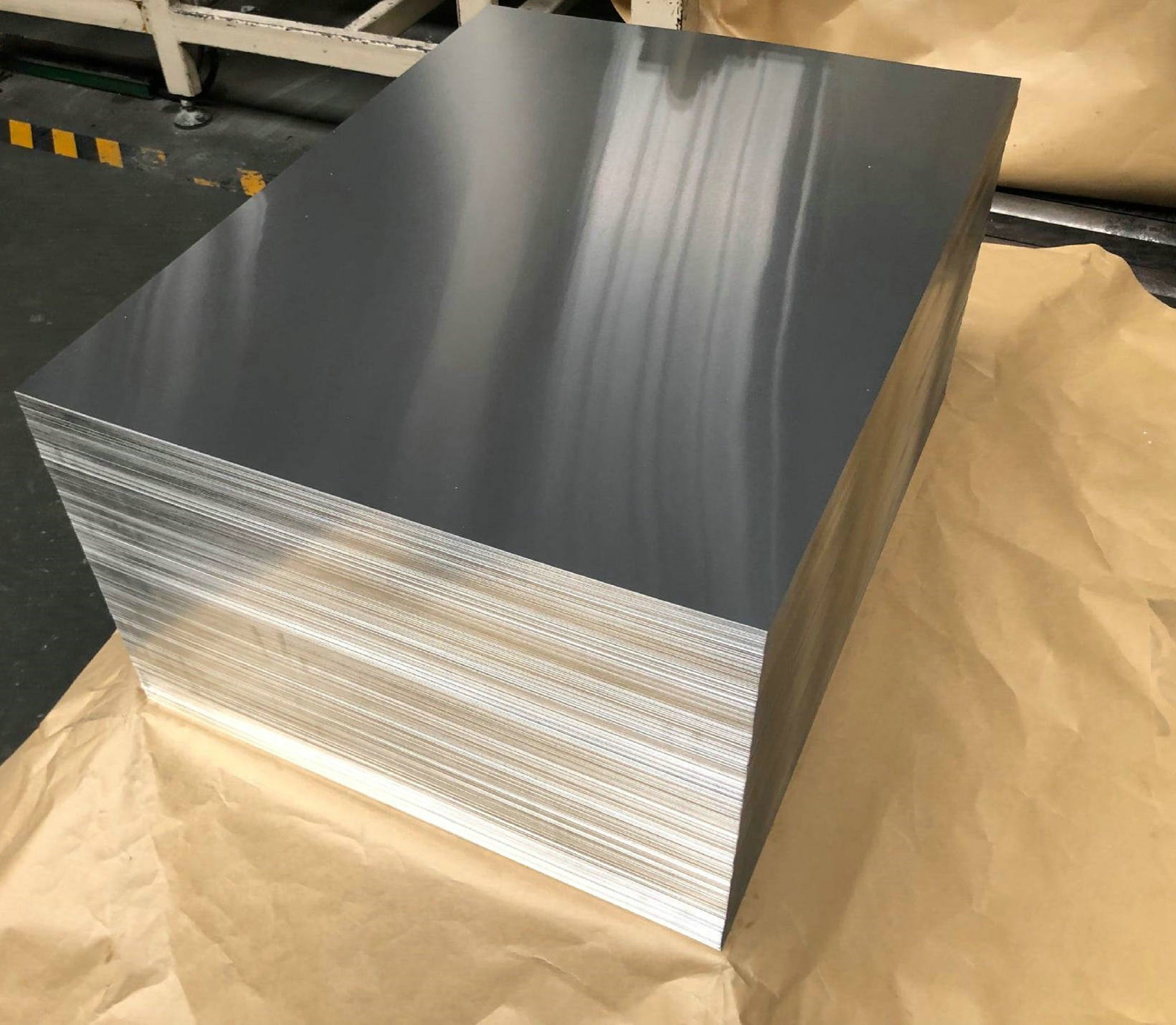

Applications: Found in everyday items like cookware, storage containers, signs, and sheet metals.

4000 Series Aluminium – Silicon Alloys

This silicon-based alloy is a popular choice in the automotive industry.

Features:

Some 4000 series alloys have a lower melting point, making them ideal for welding.

Others are heat-treated and used to build forged engine components due to their high wear resistance.

Offers a very smooth surface finish.

Good thermal and electrical conductivity.

Strong corrosion resistance.

Applications: Automotive manufacturing.

5000 Series Aluminium – Magnesium Alloys

5000 series aluminium uses magnesium as its base, often including other elements like chromium.

Features:

Incredibly corrosion-resistant.

Commonly used in marine applications like boat hulls.

Suitable for high-pressure scenarios, such as storage tanks, pressure valves, and cryogenic tanks.

Formable, weldable, and workable.

Applications: Marine engineering and high-pressure equipment manufacturing.

6000 Series Aluminium – Magnesium and Silicon Alloys

These alloys combine magnesium and silicon with aluminium, belonging to a highly versatile alloy series.

Features:

Above-average strength and good corrosion resistance.

Good machinability.

Respond well to heat treatment.

Highly versatile and widely used.

Weldable and workable.

Applications: Various structural components.

7000 Series Aluminium – Zinc and Magnesium Alloys

7000 series aluminium alloys zinc with magnesium to create an alloy used in high-tolerance and everyday applications.

Features:

Extremely strong, harder than some steels.

Highly stress-resistant.

Commonly used in aerospace, as well as daily products like sports equipment and car components.

Good weldability.

Relatively poor corrosion resistance.

Applications: Aerospace, sports equipment, and automotive manufacturing.

8000 Series Aluminium – Other Elements

This series of aluminium alloys is composed of various other elements like iron and lithium.

Features:

Often designed for specific applications (e.g., engineering and aerospace).

Share some common characteristics with the 1000 series, such as high strength and formability.

Applications: Specific engineering and aerospace industries.

the types of aluminium,the applications of various aluminum alloys

2025-03-17

Why 5052 Aluminum Is Ideal for Fuel Tanks?

2025-05-27