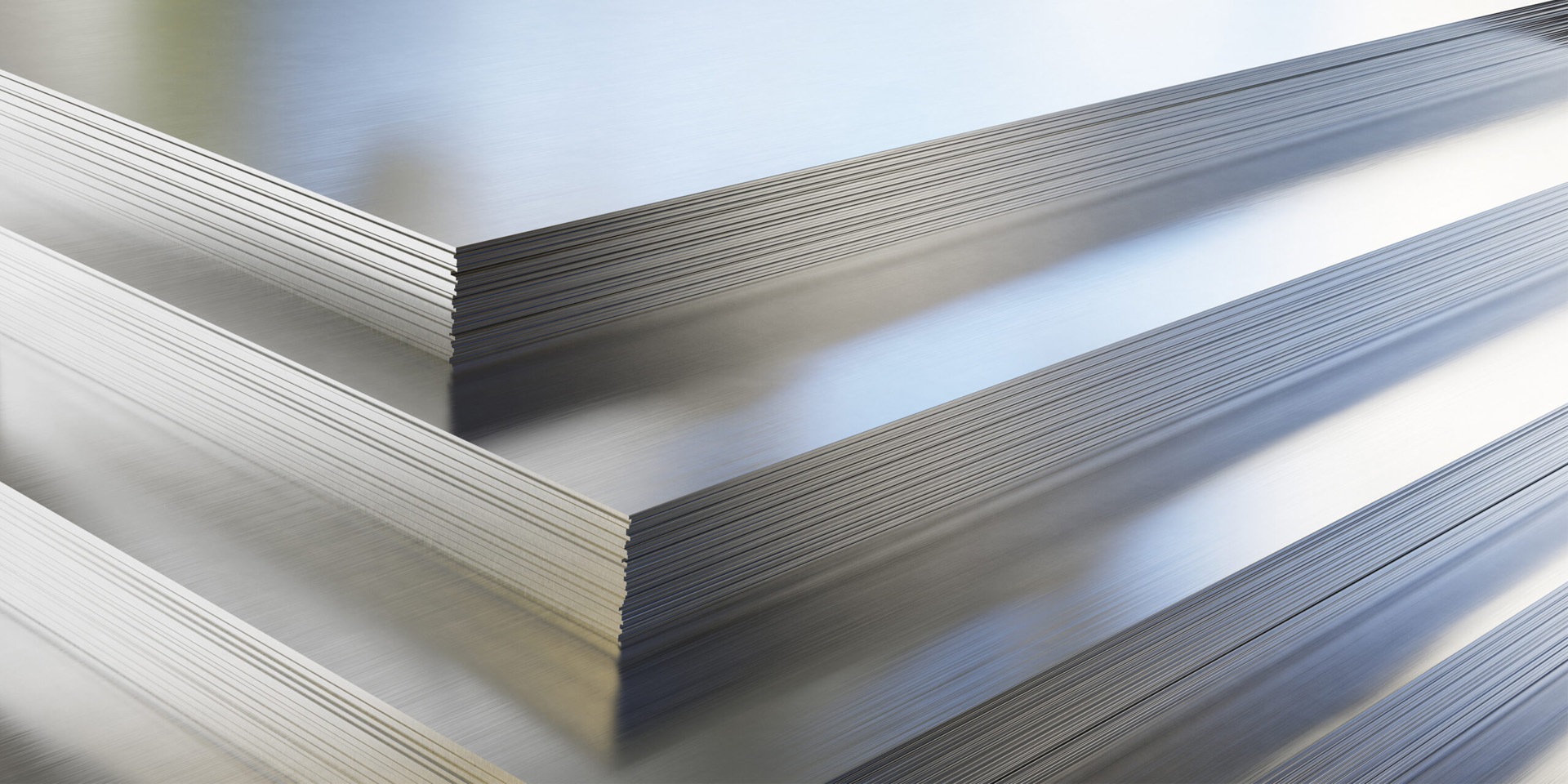

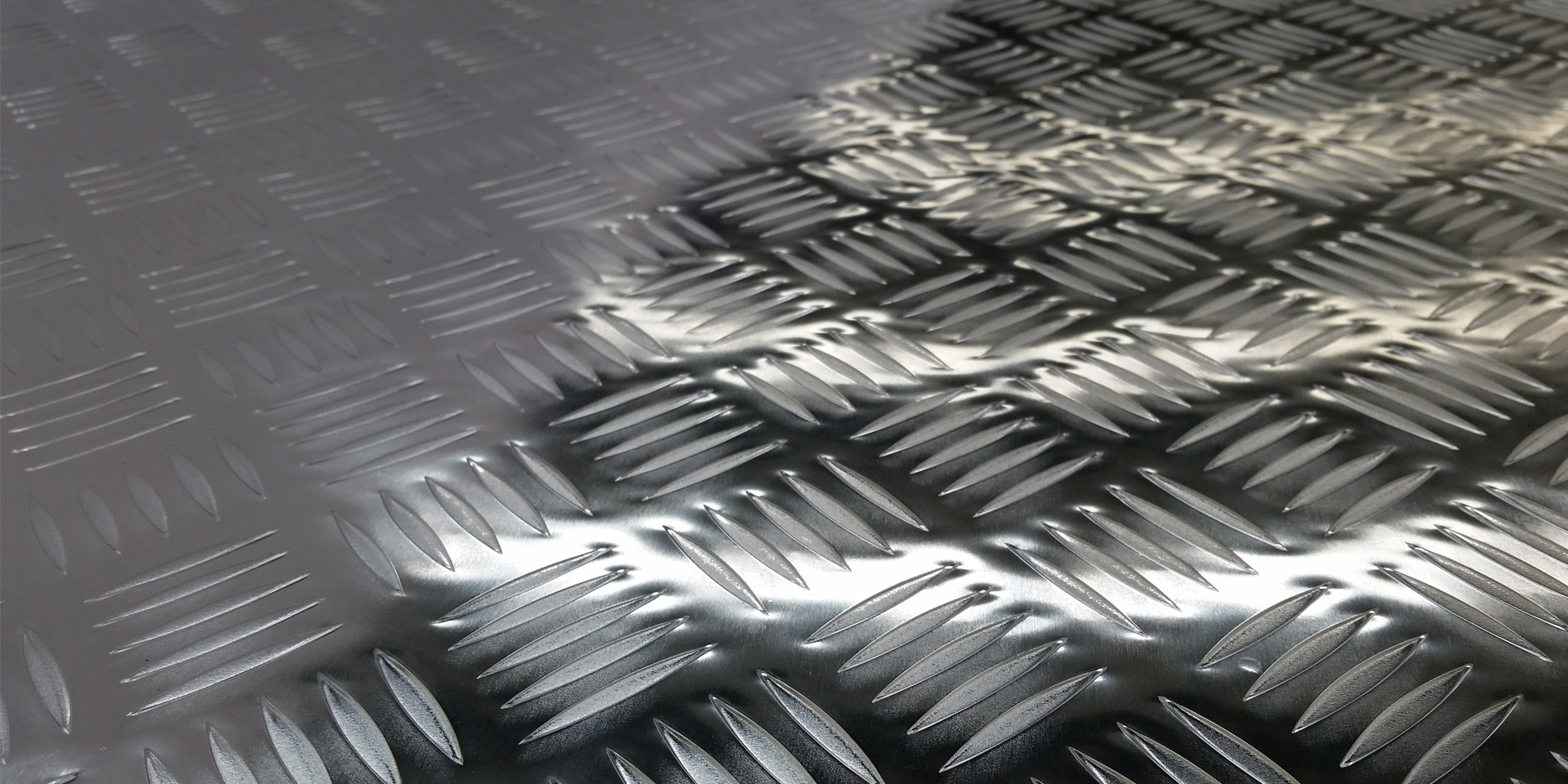

Brushed Aluminium Sheet

Brushed aluminum plate is manufactured by repeatedly scraping lines onto the aluminum plate with sandpaper. The process mainly consists of three parts: degreasing, sanding machine treatment, and water washing. During the aluminum brushing process, a special film technology applied after anodizing forms a film layer containing metal components on the surface of the aluminum plate, clearly revealing each fine silk mark, thereby creating a fine matte, silky luster on the metal surface. Brushed aluminum sheets and coils are widely used in building curtain walls, roofs, interior and exterior decoration, fine doors and windows, signage, lighting covers, brushed aluminum casings for household appliances, and common electronic product casings.

MESSAGE

Overview

Brushed aluminum refers to aluminum sheets or coils that have been treated using a specialized brushing process, creating fine and uniform linear textures on the surface. The brushing process can produce various texture effects, such as straight lines, random lines, snowflake patterns, long lines, or short lines, with the surface appearing matte or semi-gloss. During the mechanical brushing process, a high-speed rotating brush (or grinding wheel) creates relative friction with the aluminum surface, causing micro plastic deformation of the surface, which results in continuous linear patterns. This process not only enhances the appearance but also improves scratch resistance, fingerprint resistance, and anti-glare properties to some extent.

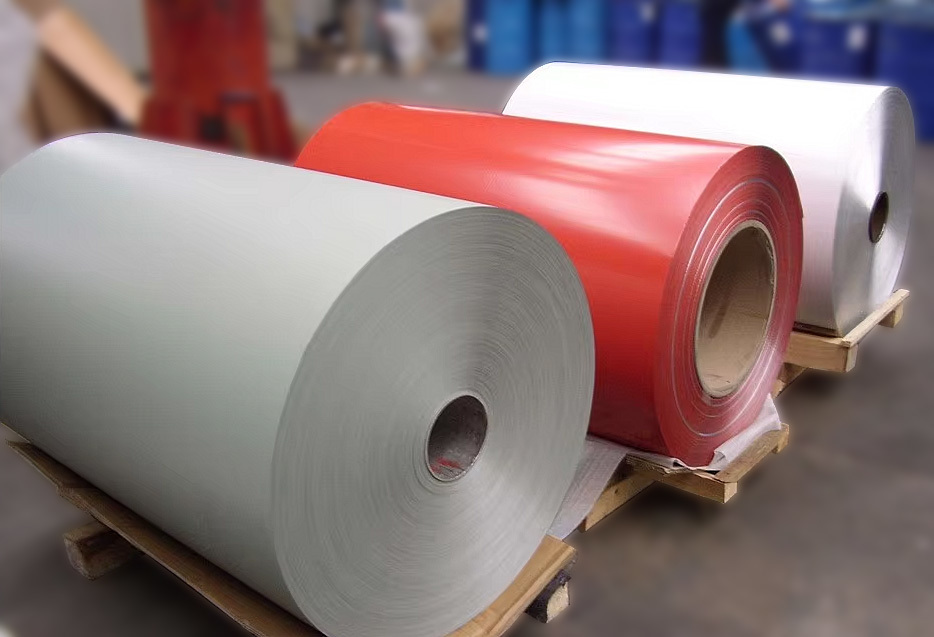

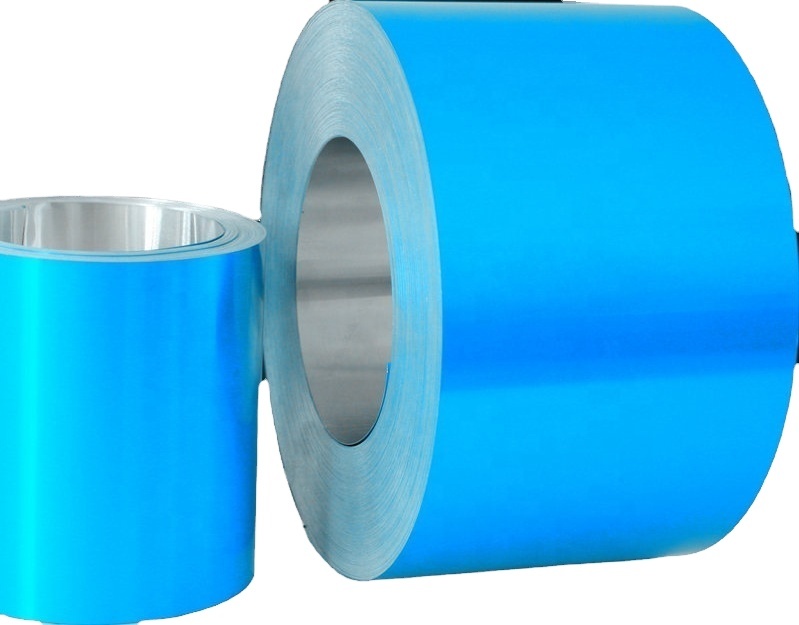

| Alloy | 1050,1100,3003,5052 |

| Temper | H14, H16, H18, H18,H24, H32, H34 |

| Thickness | 0.05mm-5mm |

| Width | 30mm-1600mm |

| Coating | PE or PVDF |

| Color | RAL Color, Silver, Golden, Bronze, Black, Pink, Red, Green |

Feature

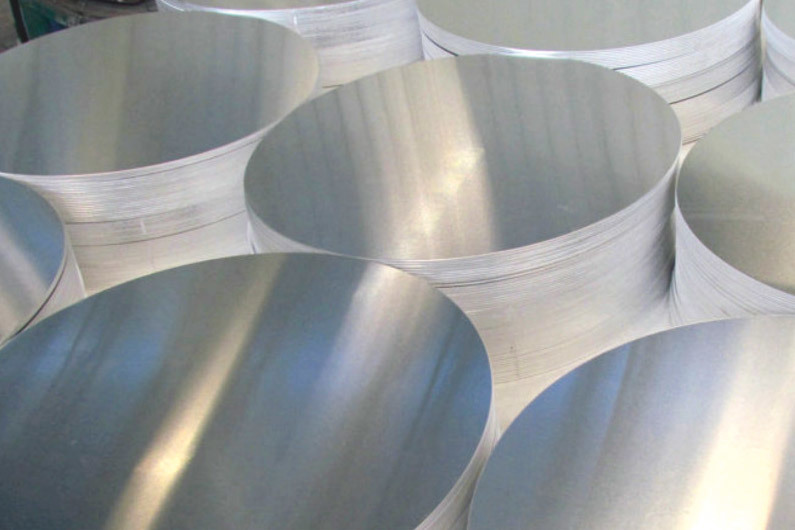

1.Surface treatment and texture diversity: The surface treatment of brushed aluminum includes processes such as anodizing and spraying, which give it a unique texture and color.

2.Physical and chemical properties: Brushed aluminum is characterized by its color stability and corrosion resistance, meaning it will not discolor even after long-term exposure outdoors. Its surface hardness reaches gemstone level, offering good scratch resistance, strong decorative qualities, and a modern metallic feel, enhancing the product’s grade.

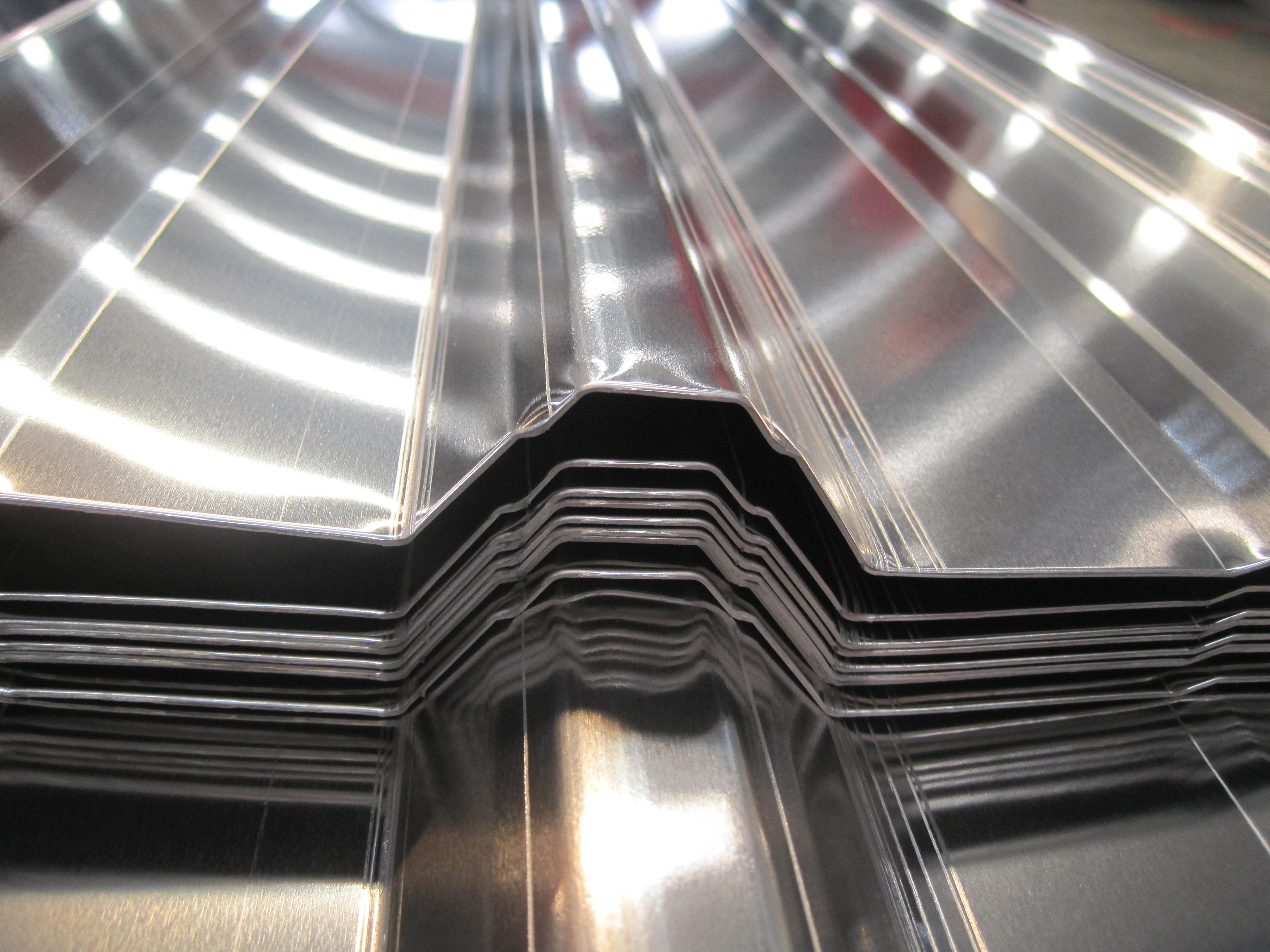

3.Wide application fields: Brushed aluminum panels are widely used in lighting reflectors, decorative lighting fixtures, solar collector reflective materials, interior building decoration, exterior wall decoration, household appliance panels, electronic product housings, furniture and kitchens, automotive interior and exterior decorations, signage, luggage, jewelry boxes, and more.

4.Environmental friendliness and sustainability: Brushed aluminum panels are recyclable materials that do not cause environmental pollution during production and use, aligning with the concept of green building. Their lightweight and easy installation characteristics also help reduce energy consumption in buildings.

Application

Brushed aluminum sheet and coil are widely used in building curtain walls, roofs, interior and exterior decoration, fine doors and windows, signs, lighting covers, brushed aluminum housings of household appliances, and common electronic product housings.

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!