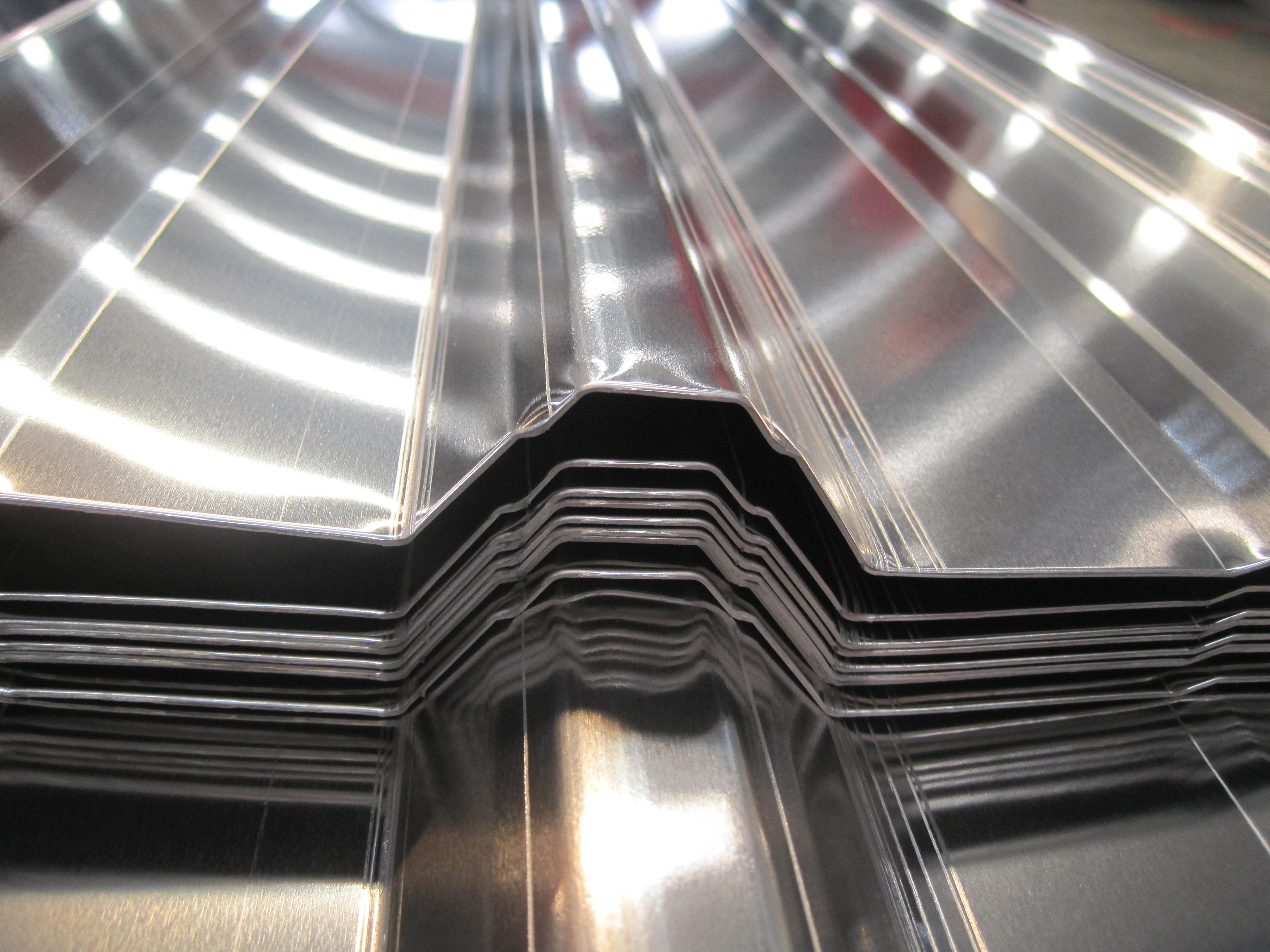

Aluminium Coil for Roofing

Aluminum coils have found widespread applications in the roofing field as an essential building material. With the development of the construction industry and the increasing requirements for building material performance, the advantages of aluminum coils in roofing applications have gradually become prominent.

MESSAGE

Overview

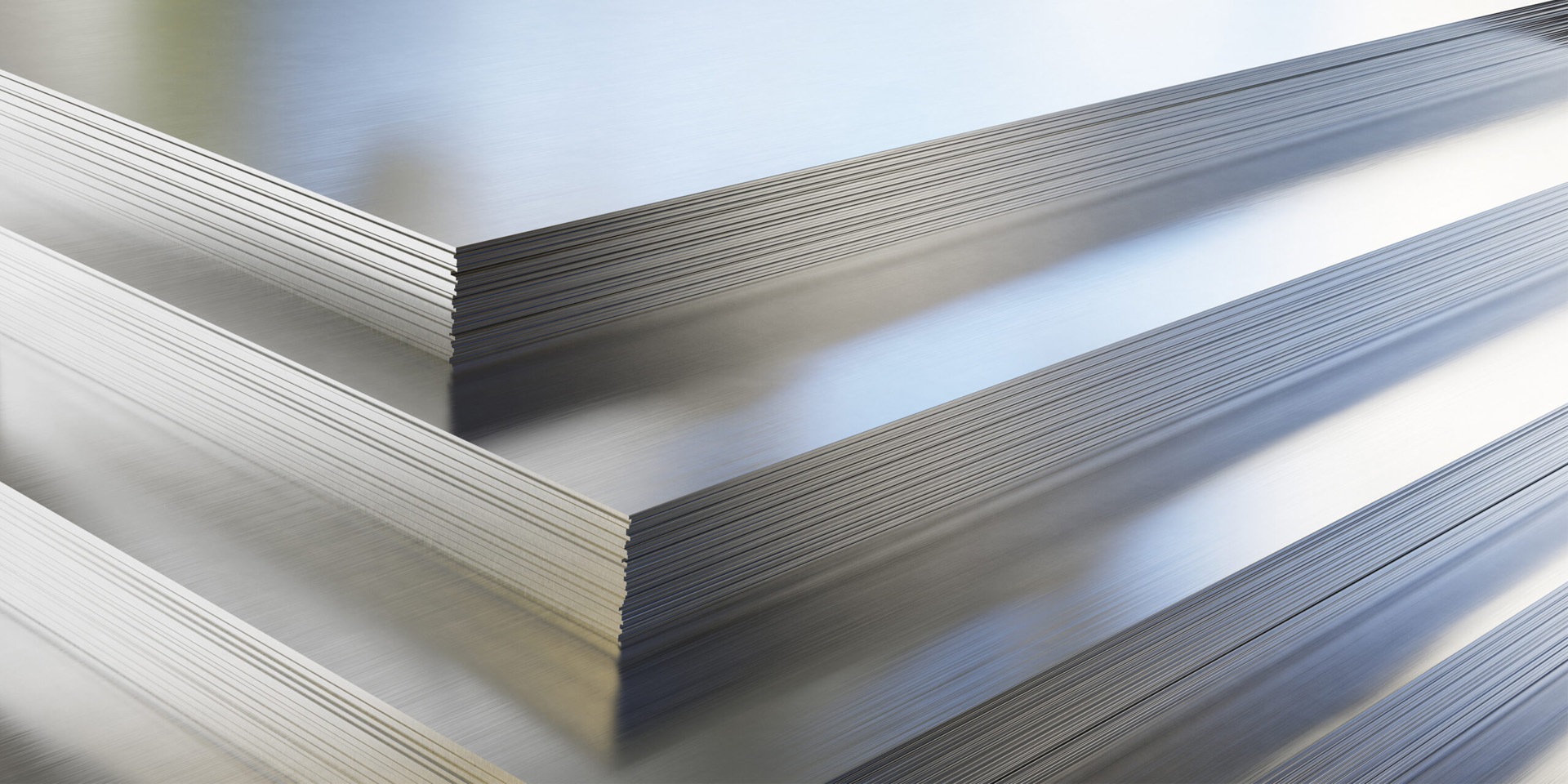

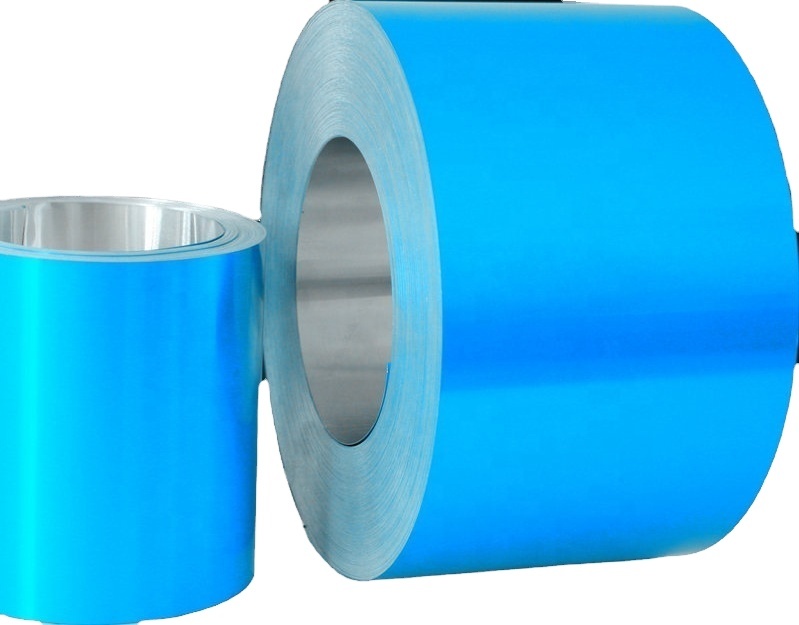

Aluminum coil for roofing is a high-performance building material widely used in modern construction. It is made from aluminum alloy (commonly 3000 series, such as 3003 and 3004) and coated with protective and decorative layers (e.g., PE, PVDF, or polyester paint). This material is lightweight, corrosion-resistant, and aesthetically versatile, making it ideal for roofing, cladding, and other architectural applications.

Feature

1.Lightweight and Durable

1)Aluminum coils are significantly lighter than steel, reducing structural load and installation costs.

2)High strength-to-weight ratio ensures long-term durability.

2.Excellent Corrosion Resistance

1)The aluminum surface forms a natural oxide layer, protecting against rust and environmental degradation.

2)Coatings (e.g., PVDF) enhance resistance to UV rays, chemicals, and extreme weather.

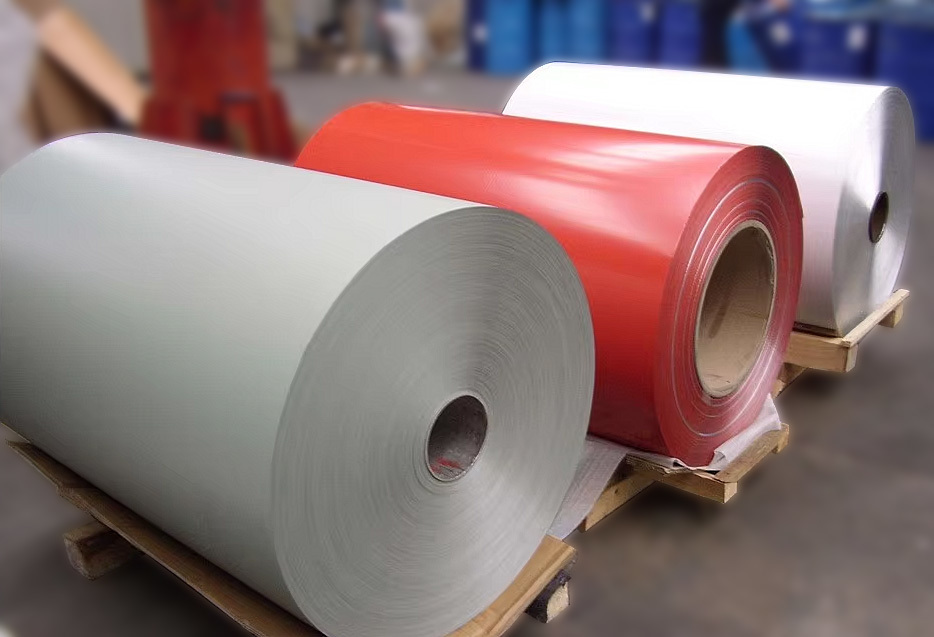

3.Aesthetic Versatility

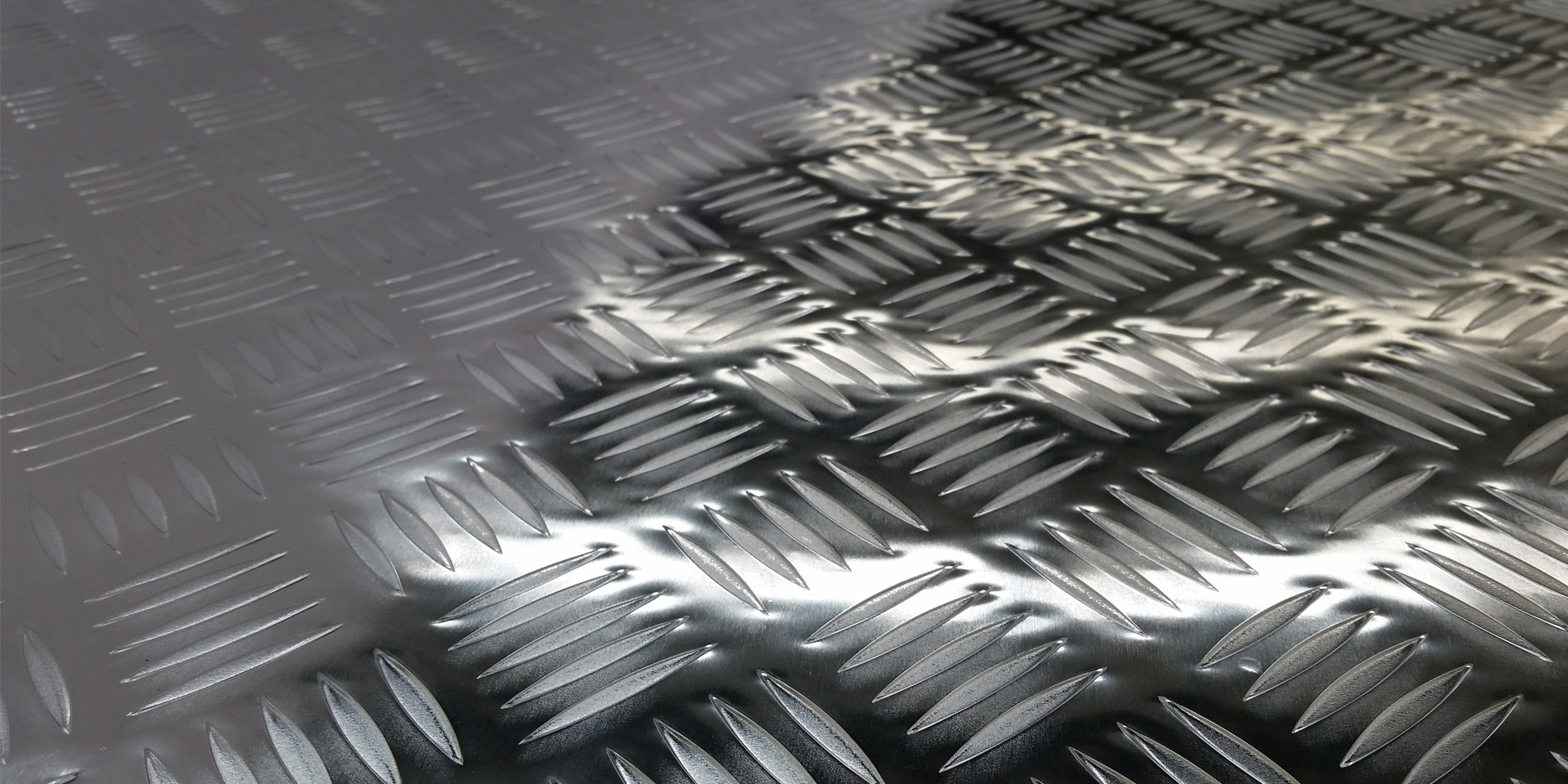

1)Available in a wide range of colors, finishes (e.g., matte, glossy, embossed), and textures.

2)Customizable to match architectural designs.

4.Weather Resistance

1) Withstands harsh weather conditions, including rain, snow, and high temperatures.

2)Low thermal expansion coefficient reduces warping or cracking.

5.Environmentally Friendly

1)100% recyclable, aligning with sustainable construction practices.

2)Energy-efficient coatings reflect sunlight, reducing cooling costs.

6.Easy Installation and Maintenance

1)Flexible and easy to cut, bend, and shape on-site.

2)Low maintenance requirements due to corrosion and weather resistance.

NEXT

NEXT

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!