08

2025

-

07

Aluminium Sheets: Properties, Selection Considerations, and Diverse Industrial Applications

Author:

Introducing aluminium sheets' properties and diverse industrial applications.

Properties of Aluminium Sheets

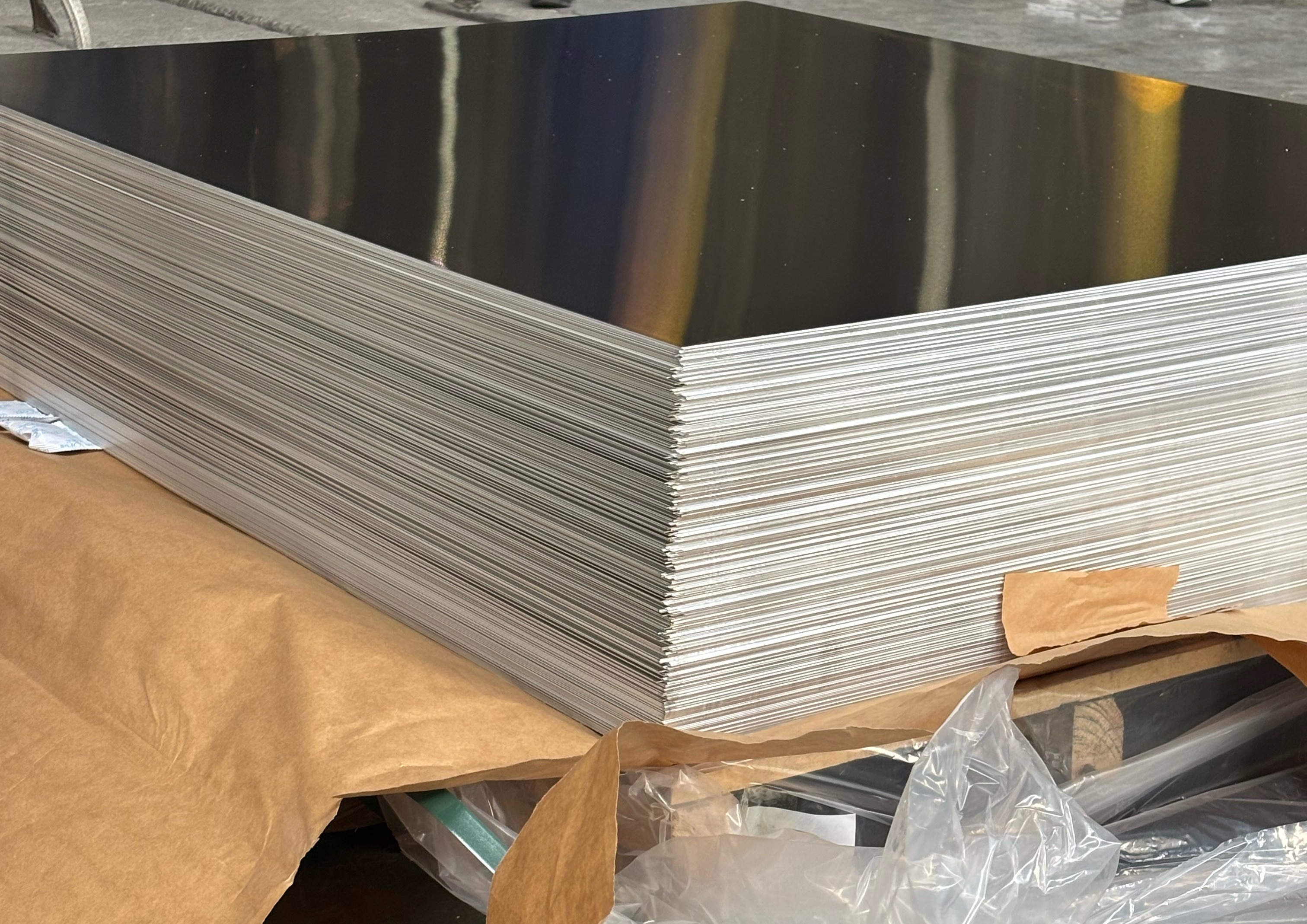

Aluminium sheets, also referred to as aluminium plates, are fabricated by pressing and then rolling the metal under high pressure into panel form. These sheets are typically manufactured to be exceptionally thin and lightweight, yet they retain sufficient sturdiness to offer remarkable versatility for a wide range of applications.

Here are some of their key properties:

Lightweight: Aluminium has a volume that is approximately one-third the mass of steel, making it an ideal choice for applications where weight reduction is crucial.

High Strength: They possess sufficient strength to be utilized in various building and structural projects.

Corrosion Resistance: Aluminium sheets demonstrate excellent resistance to corrosion in outdoor and moisture-laden environments, ensuring longevity and durability.

Easy Formability: With a relatively low melting point, aluminium sheets are easy to form into desired shapes, facilitating their use in diverse manufacturing processes.

Food-Grade Suitability: They are suitable for food-grade applications, including direct contact packaging, due to their non-reactive nature.

Impermeability: Even at extremely lightweight foil thicknesses, aluminium sheets are completely impermeable to smells and flavors, maintaining the integrity of the packaged contents.

Fireproof: Aluminium sheets are fireproof and will not burn, except in very thin films, ensuring safety in various applications.

Non-Toxic Melting: When melted, aluminium sheets do not release toxic gases, making them environmentally friendly.

High Reflectivity: Their impressive reflective properties for both heat and light make aluminium sheets suitable for use in energy-efficient heating and lighting systems.

Excellent Conductivity: Aluminium sheets exhibit excellent conductive properties for heat and electricity, approximately double that of copper, facilitating efficient energy transfer.

Recyclability: They are easily recyclable with low loss rates during the breakdown process, contributing to sustainable manufacturing practices.

Longevity and Low Maintenance: Aluminium sheets are long-lasting and require minimal maintenance, reducing replacement rates and lowering environmental impact.

Versatile Sizes and Thicknesses: They are available in a practically unlimited range of thicknesses and sheet sizes, catering to various application requirements.

Selection Considerations for Aluminium Sheets

When selecting an aluminium sheet for your project, several factors need to be considered:

Overall Surface Area: Determine the required surface area to ensure the sheet meets the project's dimensional requirements.

Metal Finishes: Explore the various metal finishes available to enhance the aesthetic appeal and functionality of the aluminium sheet. For instance, anodized aluminium offers better corrosion protection and a more visually pleasing appearance.

Thickness: Choose the appropriate thickness based on the specific demands of the job, considering factors such as structural integrity and weight constraints.

Diverse Industrial Applications of Aluminium Sheets

Due to their unique properties and versatility, aluminium sheets find applications across several industries:

Roofing: Aluminium roofing sheets are a popular choice for larger panels due to their lightweight yet sturdy construction and excellent anti-corrosion properties.

Artistic Ceilings: Dibond or composite aluminium sheets are frequently used as interior ceiling panels or large tiles, creating highly decorative yet durable design features.

Balconies: Aluminium balcony railings and balustrades are common, thanks to their lightweight yet rigid construction and weatherproof nature.

Drinks Cans and Food Industry Containers: Aluminium sheets are widely used in the production of drinks cans and other food industry containers due to their non-reactive, non-tainting, and impermeable qualities, as well as their lightweight nature for economical shipping. Reusable aluminium beer kegs are a prime example of this application.

Cladding and Fascia Panels: Aluminium composite sheeting is a leading choice for exterior cladding, internal insulation, and other panel applications in industrial, commercial, or domestic buildings and installations. Its resistance to the elements, lightweight nature, robustness, and ease of coloring make it an ideal material for these purposes.

Cranes, Trusses, Supports, and Lifting Gear: The use of lightweight materials like aluminium sheets in the lifting industry, such as on extension forks and boom lifts, can increase productivity and reduce energy costs.

Lamp Reflectors: The impressive reflective properties of aluminium sheets for both heat and light make them an ideal product for use in a wide range of commercial or domestic aluminium reflector lamps.

Shelters: Aluminium panels are widely used in the UK and elsewhere to construct lightweight yet incredibly durable covered shelters and outdoor walkways for public areas, workplaces, and more.

Caravans: Aluminium sheets are heavily relied upon for storage and accommodation applications in caravans due to their lightweight and durable nature.

Vehicle Bodies: Aluminium sheets are widely used for the bodies of cars and other vehicles, replacing steel in modern car manufacturing due to their lightweight properties. This helps reduce the overall weight of the vehicle, improving fuel efficiency and performance.

Appliances: Due to their lightweight and structural strength, aluminium sheets are a popular choice for a range of home appliances, including dryers, washing machines, and fridges. They are also widely used in electrical appliances such as laptops and phones.

In conclusion, aluminium sheets are a user-friendly sheet metal with high formability, easily cut to size for diverse applications, and perfect for a variety of projects, whether in manufacturing or DIY settings.

PREV

PREV

2025-03-17

Aluminium Sheets: Properties, Selection Considerations, and Diverse Industrial Applications

2025-07-08