28

2025

-

10

Classification of Aluminum Checker Plates

Author:

Introduction to the classification of aluminum checker plates from pattern type to alloy grade

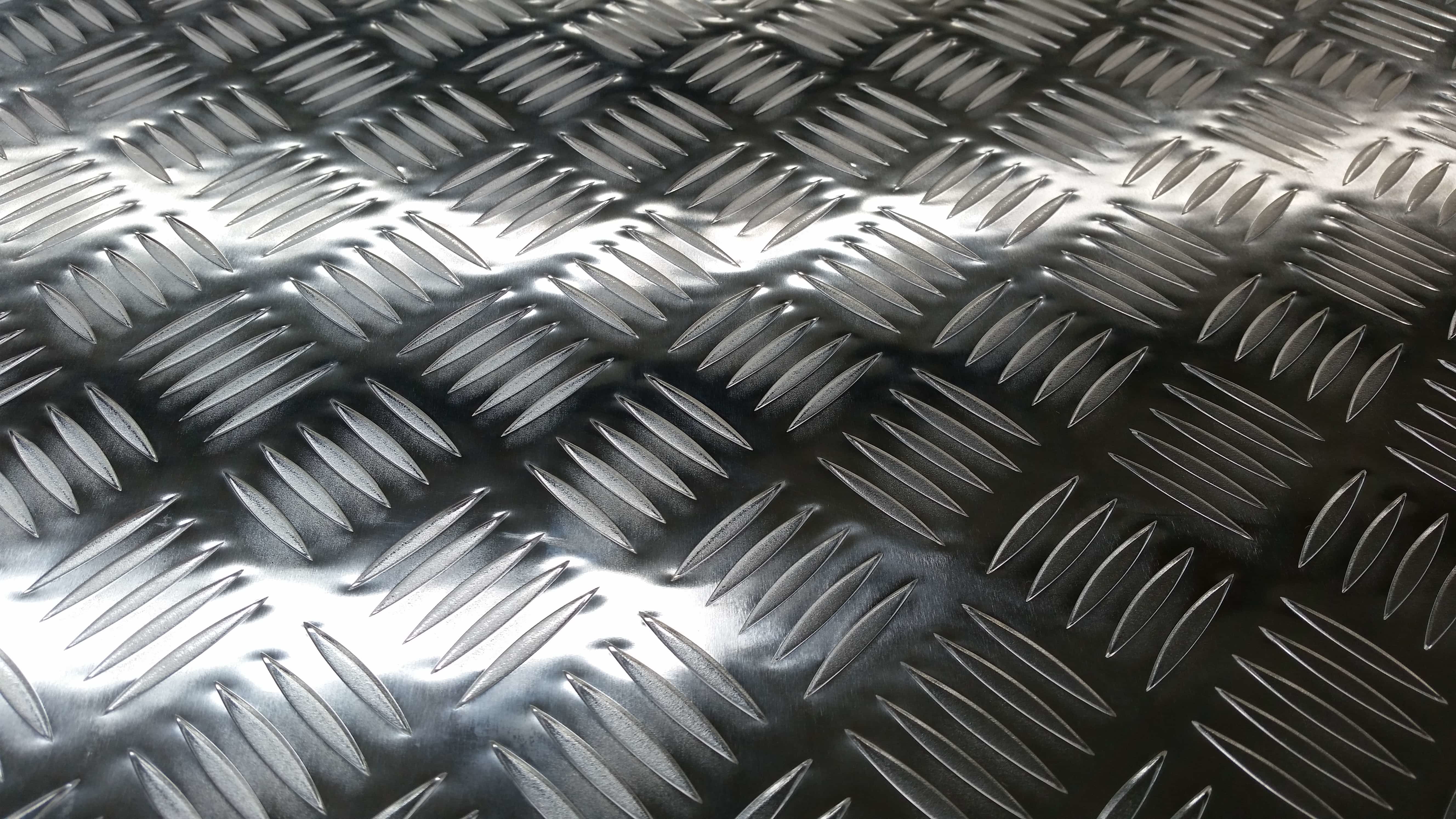

Aluminum checker plates, also referred to as anti-slip aluminum plates or aluminum tread plates, are characterized by various embossed patterns on their surface that deliver anti-slip functionality. Beyond their aesthetic appeal, these plates boast high-strength reinforcement, excellent flexibility, and the capacity to endure significant bending without fracturing. This makes them ideal for applications in the transportation and architectural decoration sectors.

Common Pattern Types of Aluminum Checker Plates

Aluminum checker plates are categorized into multiple types based on their surface patterns, including one-bar, two-bar, three-bar, and five-bar designs—all primarily engineered for anti-slip purposes. Among these, one-bar and five-bar aluminum checker plates are the most widely utilized.

One-Bar Patterned Aluminum Checker Plate: This variant features a single raised bar pattern, also known as a diamond aluminum checker plate, which creates a simple yet highly effective anti-slip surface.

Five-Bar Patterned Aluminum Checker Plate: This type consists of five parallel bars. Each pattern forms a 60-80 degree angle with its adjacent bars, providing exceptional anti-slip performance. It is extensively employed in building platforms and flooring designs.

Alloy Grades for Aluminum Checker Plates

Aluminum checker plates are mainly manufactured using 1-series, 3-series, and 5-series aluminum alloys:

1060 Aluminum Checker Plate: Renowned for its cost-effectiveness, it is suitable for common environments such as cold storage facilities and flooring applications.

3003 Aluminum Checker Plate: As a representative of the 3-series, this type offers higher strength than 1-series alloys but exhibits lower hardness and corrosion resistance compared to 5-series alloys. It is typically used in trucks and cold storage units.

5052 and 5083 Aluminum Checker Plates: These 5-series representatives deliver outstanding overall performance, including high hardness and superior corrosion resistance. This makes them well-suited for high-moisture environments like ships and vehicle compartments.

Currently, we supply anti-slip aluminum checker plates in a variety of materials, including 1100, 1050, 1060, 3003, 3004, 5005, 5052, 5083, 5754, and 6061. Custom non-standard materials are also available upon request. The surface of our anti-slip aluminum plates can undergo anodization or PE/PVDF coating treatment, significantly prolonging their service life in outdoor settings.

Our Advantages in Supplying Aluminum Checker Plates

Superior Surface Quality: Our aluminum checker plates feature a high-brightness surface. The entire production process is fully automated, ensuring no surface scratches or oil stains.

Protective Packaging: Aluminum checker plates are separated by paper sheets or covered with plastic protective films during packaging, guaranteeing the surface remains in optimal condition.

Flexible Sizing Options: ExceedMetal maintains stock of anti-slip aluminum tread plates in standard sizes, including 1220x2440mm and 1500x3000mm. Custom non-standard sizes can be cut and supplied to meet specific needs.

Cost-Effective and Efficient: We offer high-quality products at competitive prices, coupled with fast delivery times.

If you require anti-slip aluminum plates or aluminum checker plates, please contact us as soon as possible with your specific requirements and specifications!

aluminum checker plate,aluminum tread plate,aluminum chequered plate

2025-03-17

Classification of Aluminum Checker Plates

2025-10-28