18

2025

-

11

How to Cut Aluminum Sheets

Author:

Introduces several cutting methods for aluminum sheets

Aluminum is derived from bauxite, a mineral found in tropical and subtropical regions worldwide—including Australia, China, and Guinea. As the third most abundant element on Earth, it accounts for 8% of the planet’s crust. Boasting an impressive strength-to-weight ratio, aluminum is lightweight yet robust, and highly recyclable. When alloyed with other metals, it can be tailored to suit diverse applications, making it an incredibly versatile material.

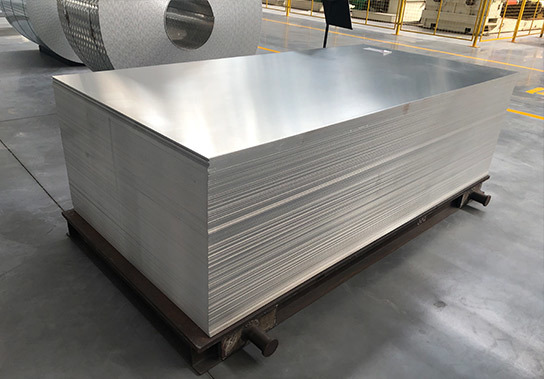

Once rolled into sheets (also referred to as aluminum plates), this material serves numerous purposes. The cutting and shaping methods vary depending on the desired final result. Aluminum sheets come in different thicknesses, determined by their intended use. They are widely utilized in the food and beverage industry for cookware and packaging, as well as in the automotive and construction sectors. Even small components of aluminum sheets are integrated into computer manufacturing.

Methods for Cutting Aluminum Sheets

There are multiple ways to cut aluminum sheets.

Safety First

Prior to cutting any metal sheet, safety must be a top priority. Anyone performing the cutting or present near the work area must wear appropriate Personal Protective Equipment (PPE), including:

Goggles, safety glasses with side shields, or a welder’s helmet

Leather gloves

Long-sleeved shirts and full-length trousers

Reinforced steel-toe boots

A hard hat

Tin Snips

Tin snips function much like a standard pair of scissors. Available in various sizes, they offer excellent maneuverability, allowing for easy cutting of curves, circles, or irregular angles. These tools can handle aluminum sheets up to approximately 1.4mm in thickness. Thanks to the precise control they provide, tin snips are the optimal choice for cutting thinner aluminum sheets with accuracy.

Angle Grinder

Angle grinders are available in corded or battery-powered models. They operate using a small rotating disk or wheel, typically spinning at 8000–11000 RPM, enabling effortless cutting, grinding, and polishing. The size and thickness of the disk should be selected based on the gauge of the aluminum being cut.

Circular Saw

Though primarily designed for cutting wood, a circular saw can slice through aluminum sheets effortlessly when fitted with the right blade. Carbide-tipped blades are recommended to achieve a smooth finish.

Band Saw

Similar to a circular saw, a band saw can cut through thicker aluminum sheets. However, it also requires the correct blade attachment for metal cutting and is not ideal for thinner sheets. Both circular and band saws can deliver relatively smooth cuts, depending on the blade used. Band saws are capable of cutting curves and shapes, though the quality of these cuts relies on the operator’s skill in keeping the saw and sheet stable for a clean finish.

Jigsaw

Like a band saw, a jigsaw can cut curves and shapes, but it also demands significant skill to maintain stability between the saw and the sheet for precise, clean cuts. Carbide-tipped blades are necessary, and lubricating the blade will ensure the smoothest possible cut.

Plasma Cutter

This tool uses an electric arc to cut through metal. While it is a costly piece of equipment, it is an excellent option for more precise cuts and complex shapes.

Oxy-Acetylene Torch

This tool generates a heated flame by burning a mixture of oxygen and acetylene, which can cut through thicker metal pieces that many other tools struggle with. It is a highly specialized piece of equipment and should only be operated by skilled welders or professionals.

Water Jet Cutter

This process involves a machine with a cutting head that emits a high-pressure water jet powerful enough to slice through the targeted material. To cut aluminum, an abrasive substance is added to the water, allowing it to penetrate the metal more quickly and easily. This method produces an extremely smooth, clean finish and is suitable for complex designs and precision cuts. It is also an environmentally friendly technique, as the water is continuously recycled, and it can handle thicker aluminum sheets—even blocks.

Hydraulic Guillotines

Hydraulic guillotines feature two blades for cutting aluminum sheets: one fixed beneath the sheet and the other moving downward to make the cut. They are available in various sizes to accommodate sheets of all dimensions.

Purchasing Aluminum Sheets

ExceedMetal is one of China’s leading aluminum suppliers. We provide aluminum sheets to a broad range of industries and offer an extensive selection of other aluminum products in addition to aluminum plates. Our product line includes various sizes and thicknesses, all manufactured, packaged, and shipped directly from our factory.

Contact us today to learn more about how we can meet all your aluminum sheet needs.

How to Cut Aluminum Sheets,Aluminum Sheet,Cut Aluminum Sheets

2025-03-17