16

2025

-

12

Which Industries Are Most Dependent on Plain Aluminum Sheets?

Author:

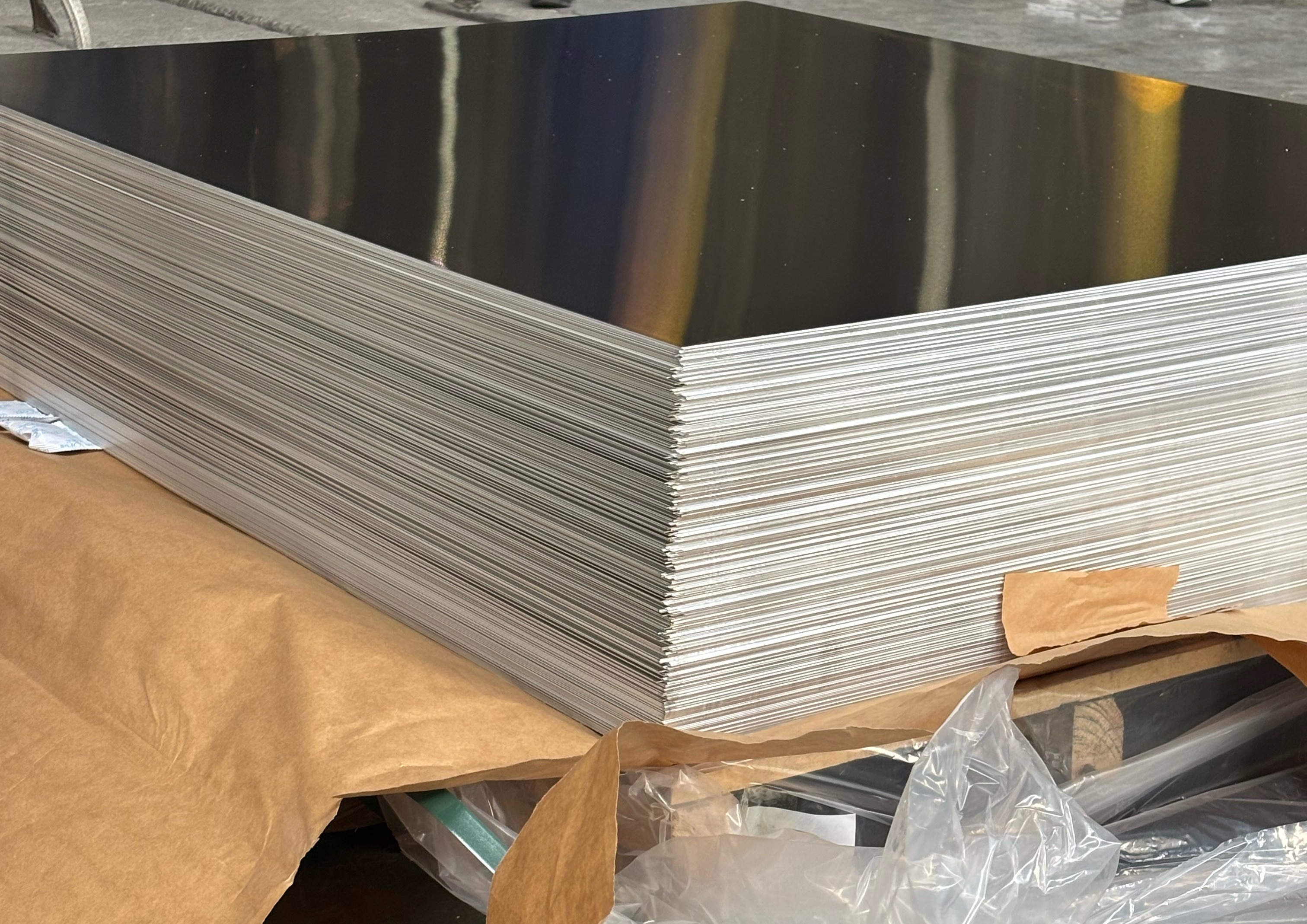

In the global industrial materials market, plain aluminum sheets have evolved into an indispensable foundational material across numerous industries, thanks to their lightweight property, corrosion resistance, and superior workability. Ranging from high-end manufacturing to daily consumer goods, their application scope keeps expanding, fueling substantial growth in market demand and industrial dependence. This article delves into the five core industries that rely most heavily on plain aluminum sheets and examines how this material is upgrading global supply chains.

Aerospace: Achieving the Ideal Balance Between Lightweight and Strength

The aerospace sector imposes stringent requirements on material performance, and aluminum sheets stand out due to their low density paired with high strength, making them the primary choice for aircraft fuselages, wings, and engine casings. Their corrosion resistance enables them to withstand extreme high-altitude conditions, while their thermal conductivity facilitates efficient heat dissipation.

Automotive Manufacturing: The Weight-Reduction Transformation in the Electric Vehicle Era

As the automotive industry transitions toward electrification, aluminum sheets are witnessing a surge in demand for body panels and chassis components. Compared with traditional steel, aluminum reduces vehicle weight by more than 30%, directly boosting the range of electric vehicles. Furthermore, its excellent corrosion resistance prolongs the service life of parts and cuts down on maintenance costs.

Architecture & Decoration: Dual Innovations in Aesthetics and Functionality

Amid the trend of green building, aluminum sheets have become a mainstream material for building facades, roofs, and interior decorations, attributed to their recyclability and weather resistance. Their surfaces can undergo anodization or painting to achieve a variety of colors and textures, satisfying design requirements from commercial complexes to art venues. Easy installation further shortens construction cycles and reduces costs.

Electronics: The Unseen Protector for Thermal Management and Component Safety

The booming development of 5G base stations, data centers, and consumer electronics has deepened the application of aluminum sheets in this industry. Their high thermal conductivity enables efficient heat dissipation, while their EMI (Electromagnetic Interference) shielding capability protects sensitive components. Being lightweight and highly workable, aluminum sheets can be formed into complex shapes for precision designs without adding excessive weight.

Packaging: A Sustainable Option for Eco-Friendly Consumption

In the packaging of food, beverages, and pharmaceuticals, aluminum sheets excel due to their non-toxicity and barrier properties. Aluminum cans block light, oxygen, and moisture, extending the shelf life of products, and boast a recycling rate of over 90%. Their smooth surfaces also allow high-quality printing, enhancing product attractiveness.

Aluminum Sheet,Plain Aluminum Sheets,The Application Industries of Plain Aluminum Sheets

2025-03-17