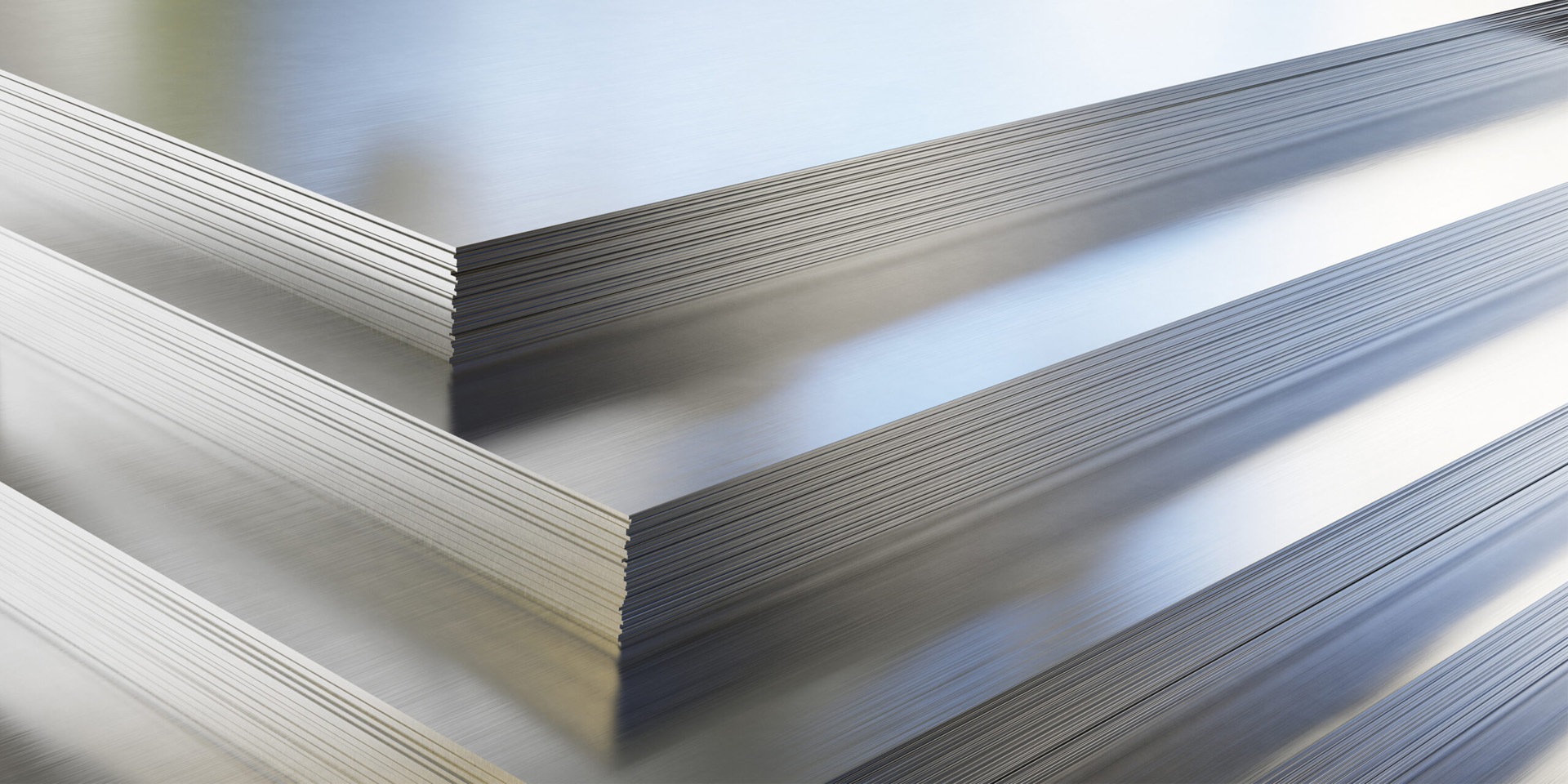

Aluminum Strip

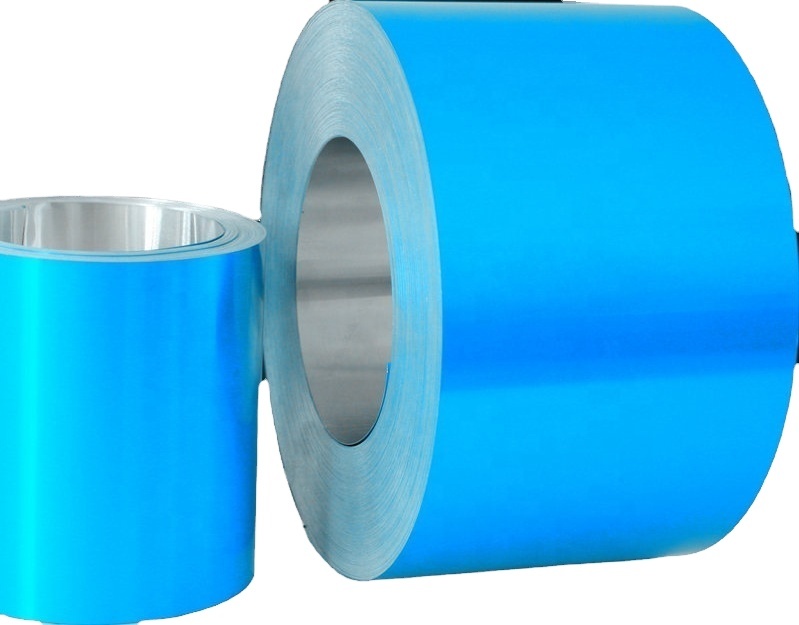

Aluminum strip is a processed aluminum product formed by slicing aluminum coils or sheets longitudinally to specific widths. It is widely used across industries due to its lightweight, corrosion resistance, and excellent formability.

MESSAGE

Overview

As a narrow and elongated aluminum product with a specific width-to-thickness ratio, aluminum strips demonstrate strong adaptability and competitiveness in numerous fields, thanks to their high-quality aluminum alloy material. They not only feature excellent corrosion resistance and durability but also can be flexibly customized in size according to different application scenarios. With characteristics such as high versatility, easy processability, lightweight, and corrosion resistance, aluminum strips have become indispensable basic materials in various industries, including architectural decoration, electronics and electrical engineering, and advertising media. They continuously drive technological progress and product innovation in these sectors, playing a crucial role in modern industrial production and daily life.

| Alloy | 1100,1050,1060,1070,1200,1350,3003,3004,3103,3104,3005,3105,5005,5052,8011 |

| Temper | HO,H12,H14,H16,H18,H19,H22,H24,H26 |

| Thickness | 0.2mm-4mm |

| Width | 10mm-1000mm |

| ID | 76mm,150mm,305mm,405mm,505mm |

Feature

1.Lightweight and High-strength: Aluminum strips have a low density, making them lighter than many other metal materials, which facilitates transportation and installation. Meanwhile, they offer high strength, meeting various structural and functional requirements and enabling lightweight designs.

2.Excellent Corrosion Resistance: Aluminum strips made from aluminum alloys easily form a dense oxide film on the surface, effectively resisting corrosion from rainwater, moisture, acids, alkalis, and other corrosive substances. Even in harsh environments such as humid or industrial-polluted areas, they maintain stable performance over the long term, reducing maintenance costs.

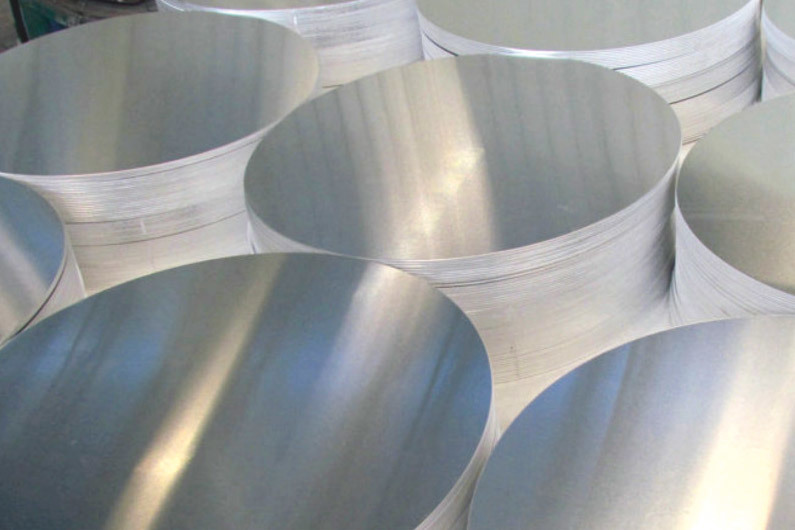

3.Good Workability: Aluminum strips have high plasticity and can be easily bent, stamped, welded, cut, and subjected to other processing operations. They can be quickly formed into complex shapes, improving production efficiency and reducing processing difficulty and costs.

4.Excellent Electrical and Thermal Conductivity: They exhibit good electrical and thermal conductivity, making them suitable for use as wires in electrical equipment, heat dissipation components, etc., meeting the specific requirements of the electronics and electrical fields.

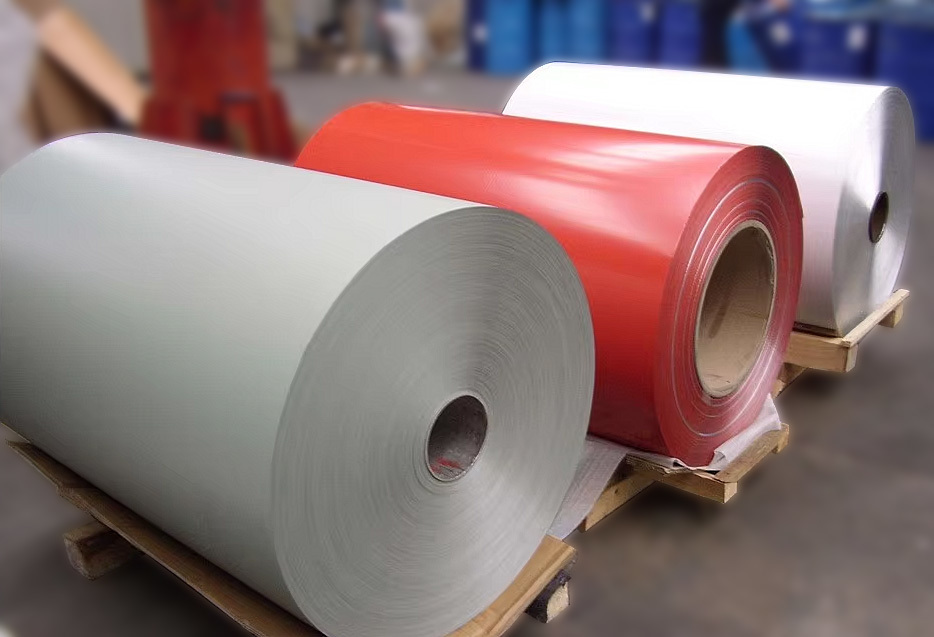

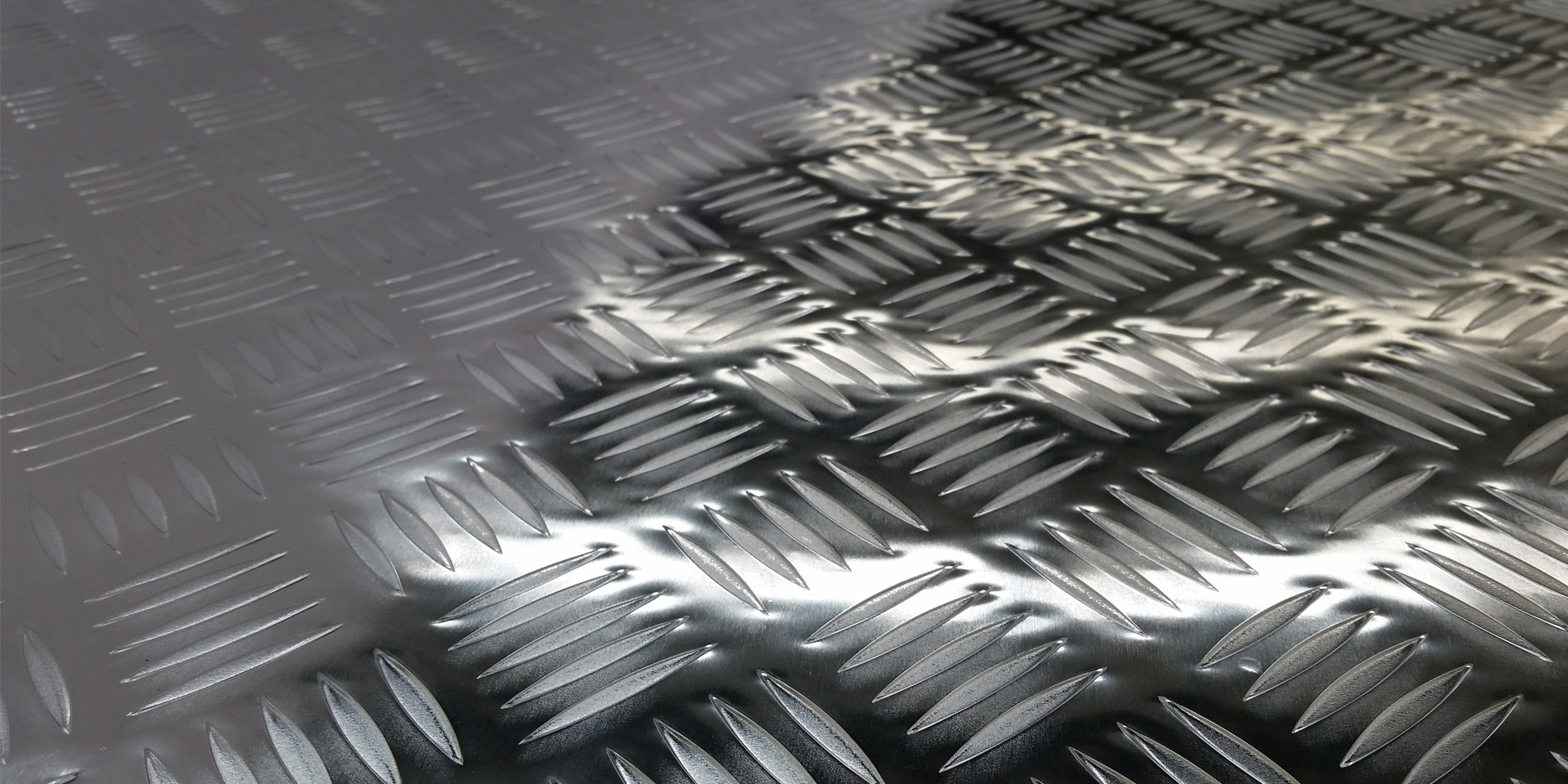

5.Aesthetic and Decorative Qualities: With a smooth and flat surface, aluminum strips can be given a variety of colors and textures through processes such as anodizing, painting, and electroplating. They are widely used in the decorative field to enhance the visual appeal of products.

Application

Aluminum strips are widely used in industrial manufacturing, architectural decoration, and advertising media fields.

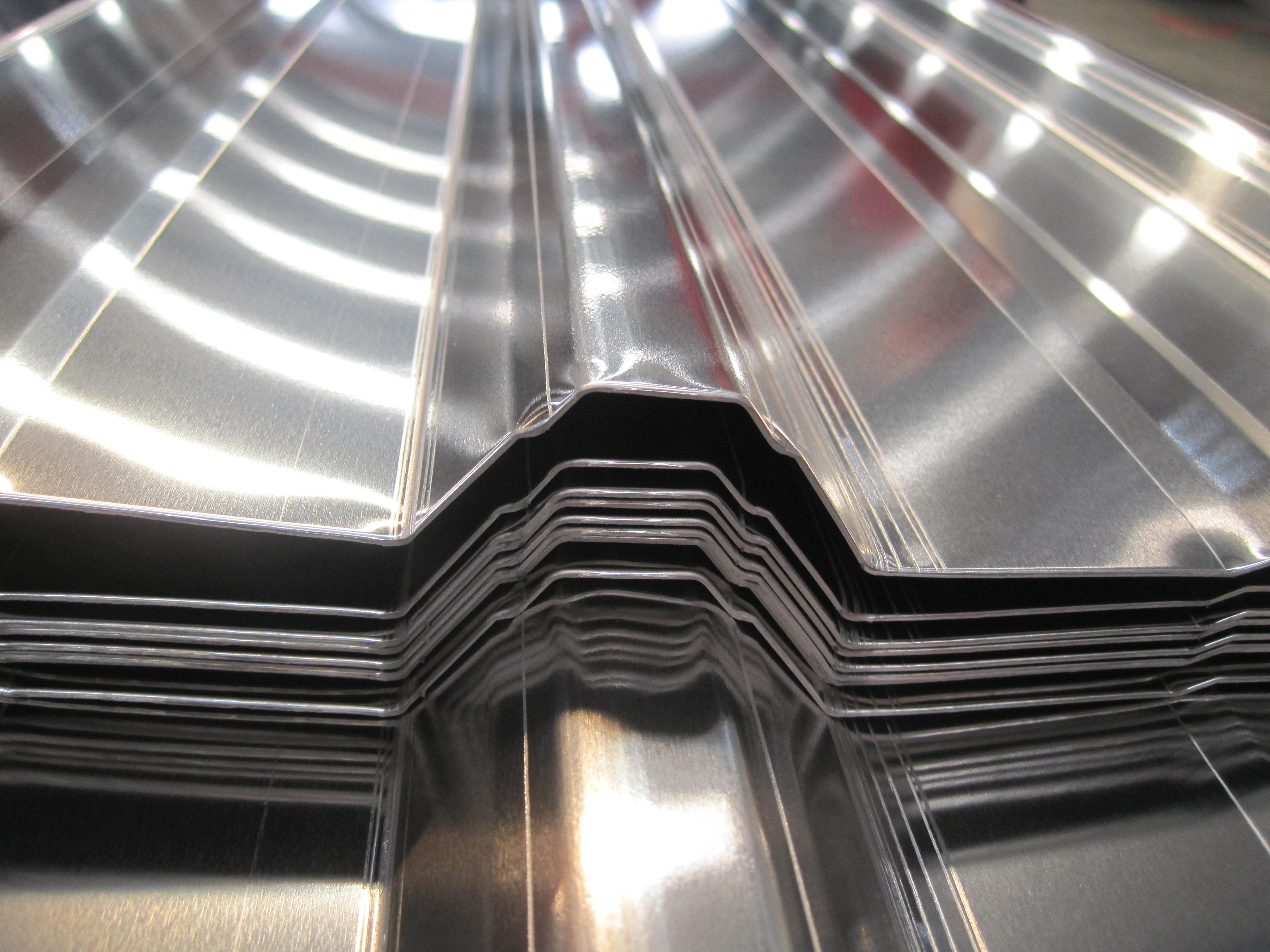

1.In industrial manufacturing, they are applied in various industries such as lighting, printing, and packaging, providing support for different production processes.

2.In the field of architectural decoration, due to their aesthetic and durable properties, they are extensively used in indoor and outdoor decoration projects.

3.In the advertising and media field, through flexible processing and diverse surface treatments, aluminum strips become ideal materials for creating various advertising displays, effectively enhancing the promotional effect.

NEXT

NEXT

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!