keyword:

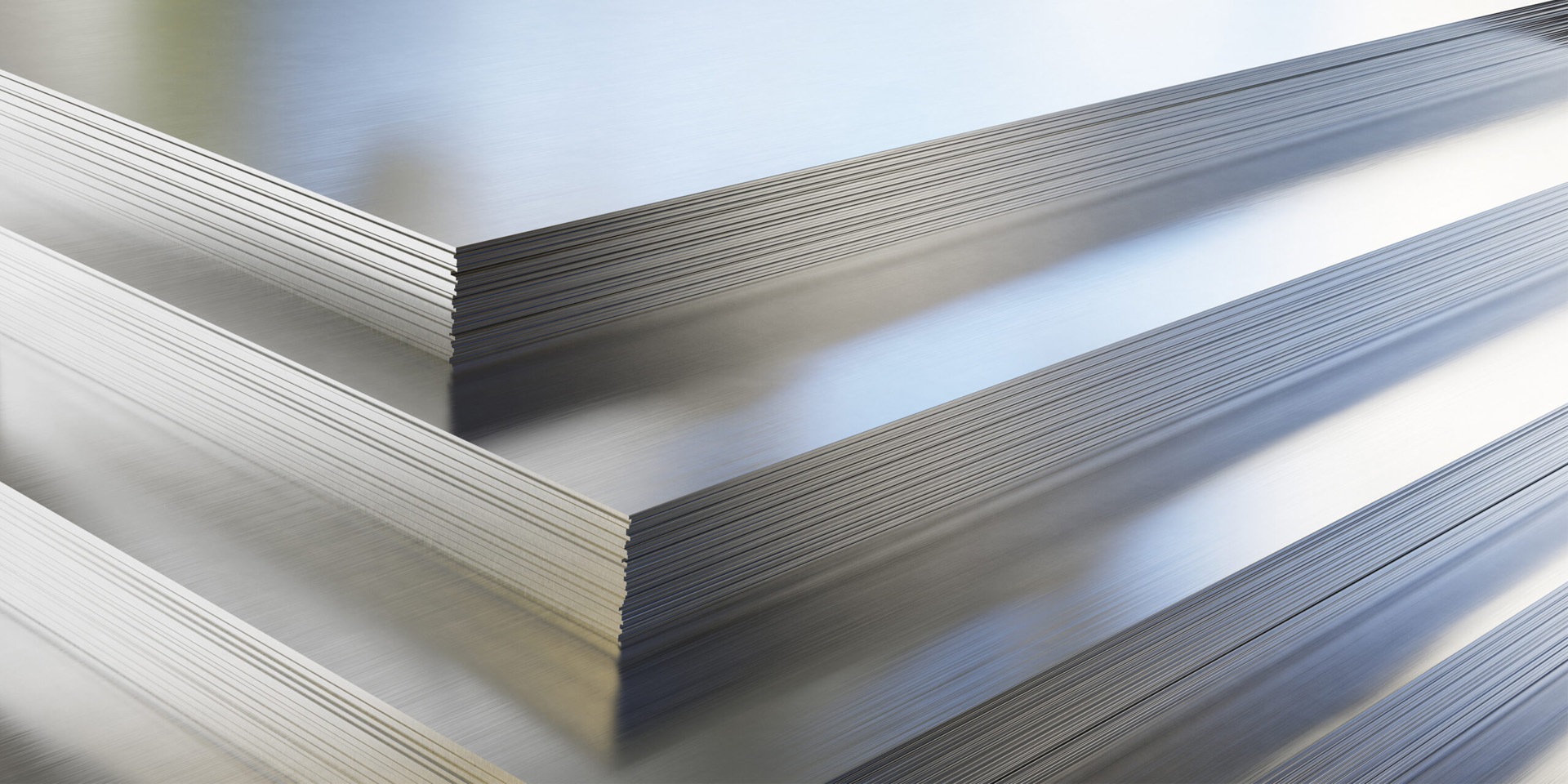

Brushed aluminum plate is manufactured by repeatedly scraping lines onto the aluminum plate with sandpaper. The process mainly consists of three parts: degreasing, sanding machine treatment, and water washing. During the aluminum brushing process, a special film technology applied after anodizing forms a film layer containing metal components on the surface of the aluminum plate, clearly revealing each fine silk mark, thereby creating a fine matte, silky luster on the metal surface. Brushed aluminum sheets and coils are widely used in building curtain walls, roofs, interior and exterior decoration, fine doors and windows, signage, lighting covers, brushed aluminum casings for household appliances, and common electronic product casings.

keyword:

Brushed aluminum sheet are made of aluminum, by laminated and extruded, brushed in silver, champagne, rose and gold colors, with various applications in construction, transportation, advertising production, production of electrical and household appliances, automotive industry and others.

keyword:

The 1050 brushed aluminium sheet is a type of industrial pure aluminum in the 1000 series, with an aluminum content of ≥99.5%, complying with international standards (e.g., GB/T 3880-2006). Its surface is treated with a brushing process to create fine linear textures, combining metallic luster with a matte finish. It is widely used in applications requiring both aesthetics and functionality.

keyword:

The 3003 brushed aluminum sheet is made from Al-Mn alloy (1.0-1.5% manganese), with parallel textures formed by mechanical brushing, combining metallic luster and matte finish.It offers 20% higher strength than pure aluminum (e.g., 1050) while maintaining decorative appeal and processing flexibility, widely used in construction, home appliances, transportation, etc.

keyword:

PRODUCTS

BLOG