28

2025

-

04

Why use the aluminum coil in thermal insulation?

Author:

Introduce the reasons for using aluminum coils in thermal insulation.

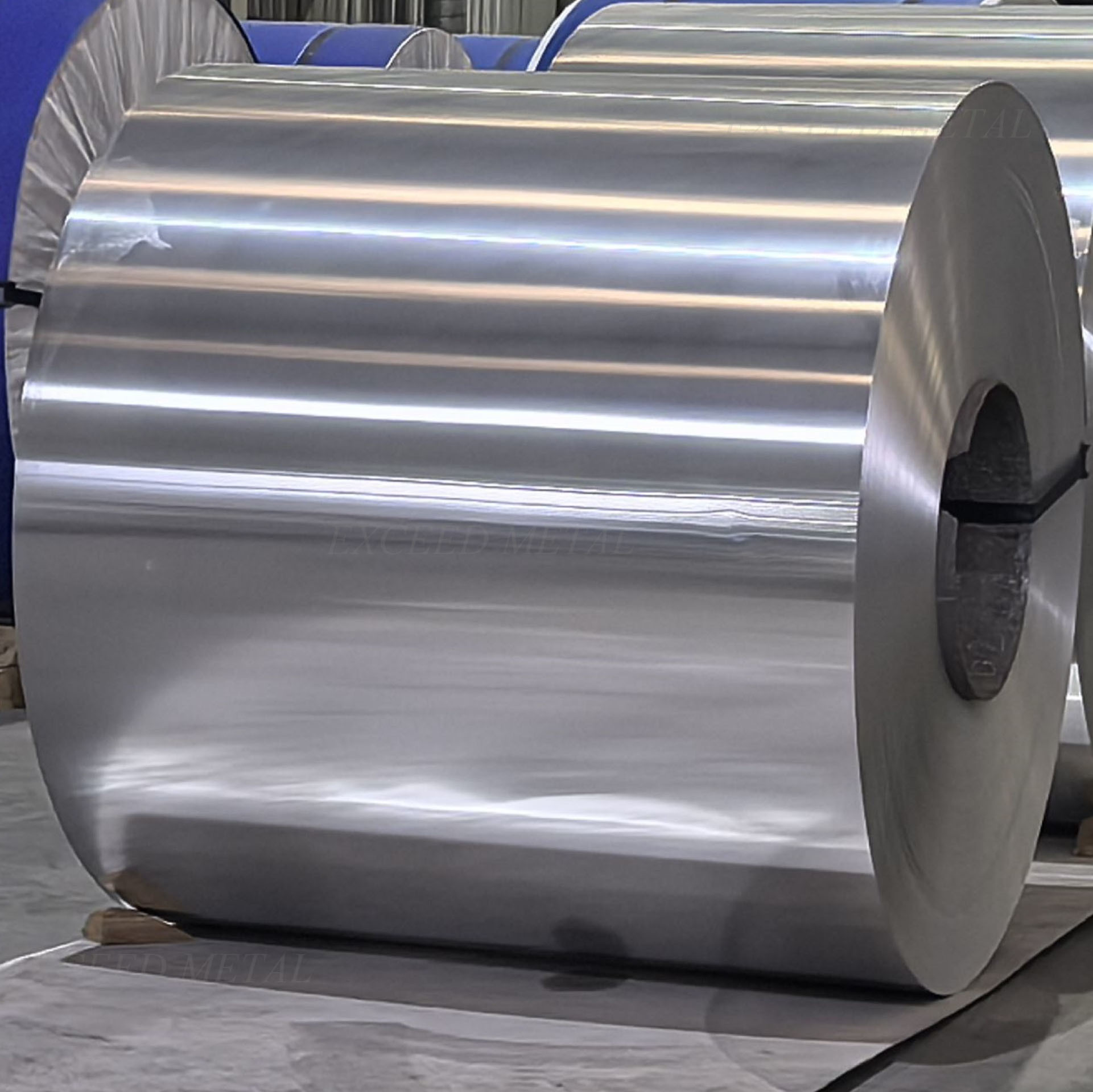

As thermal insulation aluminum coil manufacturers continue to innovate and evolve, production efficiency has increased and costs have decreased, leading to the growing popularity of thermal insulation aluminum rolls. Pipeline corrosion insulation is extensively utilized in thermal insulation projects, not only due to its cost-effectiveness but also because it combines the advantages of traditional metals.

Key Advantages of Thermal Insulation Aluminum Coils:

1.Durability: Thermal insulation aluminum rolls are commonly employed in environments requiring heat preservation and pipeline anti-corrosion, where conditions are often harsh, damp, and corrosive. Unlike iron and zinc, which are susceptible to rust and corrosion, aluminum coils resist erosion and maintain their integrity for extended periods. This eliminates the need for frequent re-insulation, saving enterprises significant time, labor, and resources.

2.Aesthetic Excellence: A company's image is crucial in today's competitive market. Traditional thermal insulation materials like iron and zinc tend to oxidize, becoming dull and unattractive over time. Corrosion and rust further degrade their appearance, negatively impacting the corporate image. In contrast, aluminum coils boast a vibrant, corrosion-resistant finish that remains bright and unoxidized, enhancing the overall aesthetic of the installation and contributing positively to the company's visual identity.

3.Recyclability and Cost Efficiency: When iron, zinc, and other thermal insulation materials corrode, their recyclability diminishes significantly. However, aluminum coil manufacturers have capitalized on the recyclability of aluminum, offering products with a high recycling rate. Recycling scrap aluminum can recover 60-70% of the initial cost, providing substantial economic benefits for enterprises.

Common Alloys of Thermal Insulation Aluminum Coils:

1000 Series Pure Aluminum Coil: Primarily used in municipal pipelines and roof insulation due to its pure aluminum composition.

3000 Series Aluminum-Manganese Alloy Coil: With higher hardness, it is suitable for external packaging components such as tanks, machine parts, refrigerators, and air conditioners.

5000 Series Aluminum-Magnesium Alloy Coil: A corrosion-resistant aluminum alloy used in specialized environments like marine, shipping, chemical, and power industries.

Aluminum Coil for Thermal Insulation

2025-03-17

Why use the aluminum coil in thermal insulation?

2025-04-28