19

2025

-

08

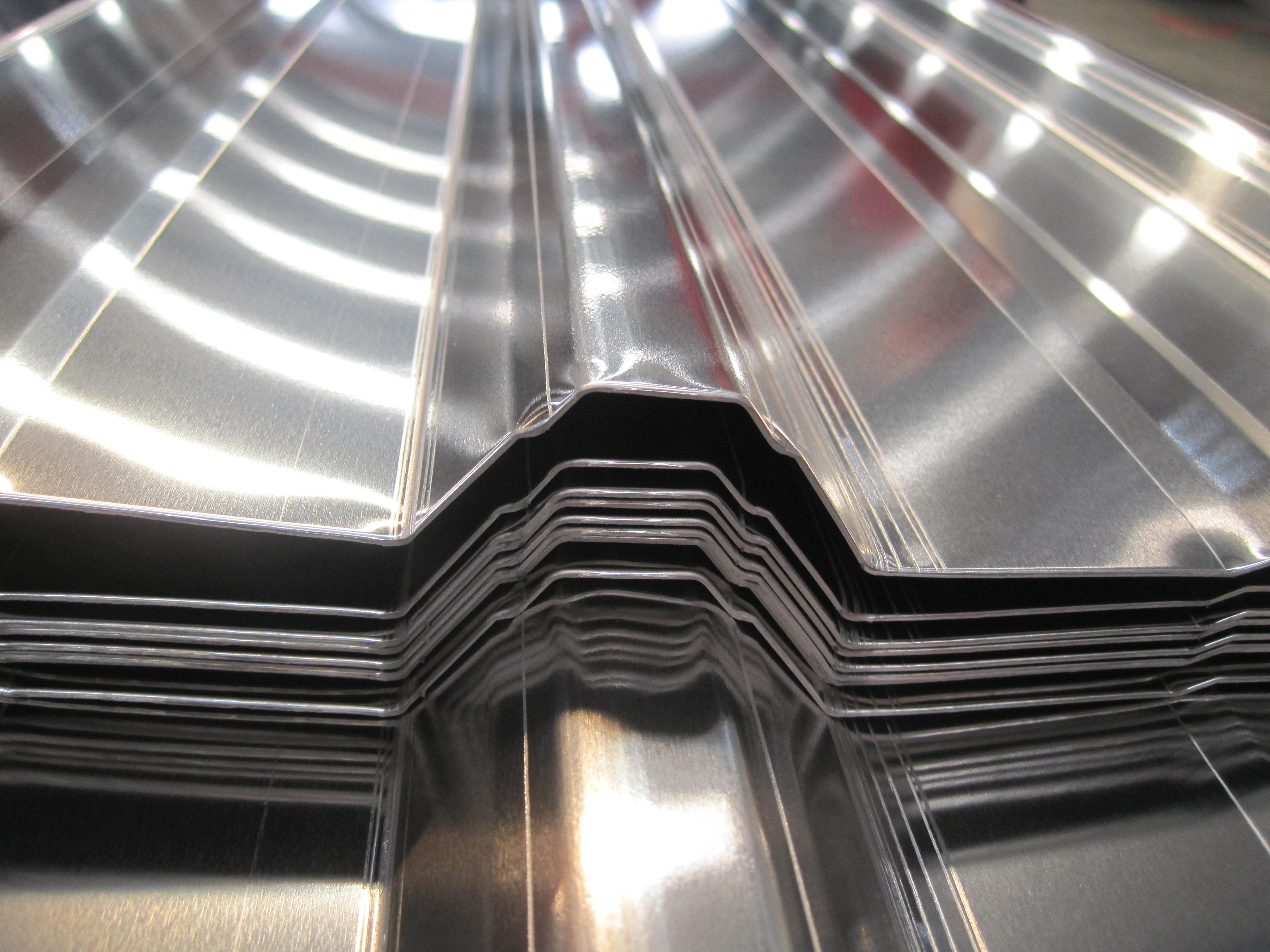

Aluminum Roofing Sheets: The Preferred Choice for Modern Construction Worldwide

Author:

Introducing aluminum roofing sheets for corrosion resistance, light weight and sustainability

In the global construction sector, selecting roofing materials has a direct influence on a building’s service life, maintenance costs, and environmental performance. In recent years, aluminum roofing sheets have become a mainstream substitute for traditional steel roofing, thanks to their lightweight properties, corrosion resistance, and longer lifespan. Whether used in residential, commercial, or industrial projects, these sheets are winning greater market acceptance and have become a key focus for overseas builders and property owners.

Corrosion Resistance

Although steel roofing has high strength, long-term exposure to moisture, acid rain, or coastal conditions can cause rust and corrosion. This means regular anti-rust coatings or replacements are necessary. In contrast, aluminum roofing sheets naturally develop a protective oxide layer that effectively blocks water and oxygen. Even without extra coatings, they can resist salt spray and acid rain. This makes them perfect for areas with changeable climates or high humidity, greatly lowering long-term maintenance costs.

Lightweight Design

With a density only one-third of steel, aluminum roofing sheets reduce the pressure on a building’s structural load—this is especially helpful when retrofitting older buildings or working on designs sensitive to weight. Their lightweight feature also makes transportation and installation easier, cutting down on labor and time costs. In contrast, steel roofing requires more complex support structures and specialized equipment during installation.

Eco-Friendliness and Sustainability

Aluminum is fully recyclable, and the energy needed for recycling is just 5% of that required for primary aluminum production. Choosing aluminum roofing aligns with global green building trends and reduces resource depletion. Moreover, these sheets have a lifespan of over 30 years, which is much longer than the average durability of steel roofing. This further reduces carbon emissions throughout the product’s lifecycle.

Recommended Alloys: 3000 and 5000 Series

For different application scenarios, 3000-series aluminum-manganese alloys (e.g., 3003, 3004) and 5000-series aluminum-magnesium alloys (e.g., 5052) are the best choices. The 3000 series balances strength and corrosion resistance, making it suitable for moderate climates. The 5000 series, which has added magnesium, performs better in impact resistance and weatherability—it is ideal for areas prone to strong winds, heavy rain, or temperature changes. Both alloy series are easy to form, allowing for complex roof designs.

From durability to sustainability, aluminum roofing sheets are setting new standards in the construction industry. For overseas projects that prioritize long-term value and environmental responsibility, adopting aluminum roofing is both a technological upgrade and a forward-looking investment.

aluminum roofing sheets

2025-03-17

Aluminum Roofing Sheets: The Preferred Choice for Modern Construction Worldwide

2025-08-19