16

2025

-

09

Thermal Insulation Solution: Polysurlyn Moisture Barrier Embossed Aluminum Coil

Author:

Why Choose Polysurlyn Moisture Barrier Embossed Aluminum Coil for Insulation?

Polysurlyn moisture barrier embossed aluminum coil is essentially a composite insulating material that merges the high strength of aluminum coil with the outstanding moisture-blocking performance of Surlyn film.

Material Composition of Polysurlyn Moisture Barrier Embossed Aluminum Coil

1. Aluminum Coil Substrate

The commonly adopted materials are 1060 pure aluminum and 3003 aluminum-manganese alloy, with a thickness ranging from 0.2mm to 1.5mm and a width between 20mm and 1600mm. The aluminum coil itself has strong corrosion resistance; among them, 3003 alloy contains manganese, making it especially suitable for high-humidity or corrosive environments (e.g., chemical plants and coastal regions).

2. Polysurlyn (Surlyn Film) Moisture Barrier

Material Features: Surlyn film is an ionomer (ethylene-methyl methacrylate copolymer) manufactured by DuPont. It is bonded to the aluminum coil via a hot-press lamination process, with a thickness of approximately 0.076mm and a weight of 0.08kg per square meter. Its unique structure consists of three layers:

The first layer is a dense film: in 10 moisture-proof test holes, the number of water seepage holes is no more than 5, delivering excellent waterproof performance.

The second layer is a one-way water-absorbing film: it absorbs water vapor around the aluminum material and releases it irreversibly, preventing internal corrosion.

The third layer is an adhesive film: it enhances the bonding strength with the aluminum coil and can withstand harsh conditions like hot water and low temperatures for a long time.

Performance Advantages: It has a temperature resistance range from -40℃ to +360℃, resists chemical corrosion (such as acids and alkalis), and still maintains bonding performance after thermal aging.

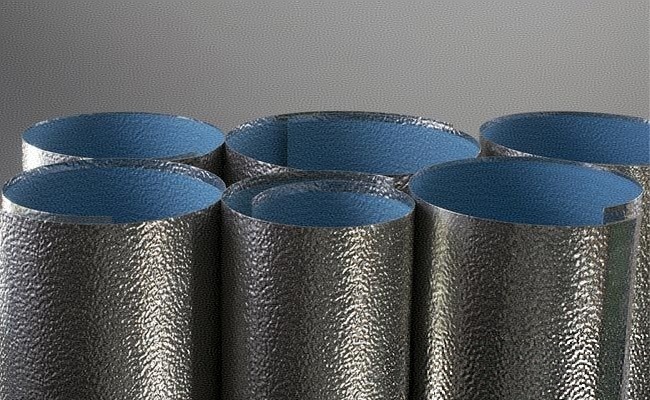

3. Embossing Design

The common embossing type is the orange peel pattern, with an embossing depth of 0.1mm to 0.15mm. Processed by a two-roll mill, it not only improves the surface hardness and wear resistance of the aluminum coil but also enhances its aesthetic appeal. The orange peel-patterned aluminum coil has good thermal conductivity and heat dissipation performance, making it suitable for pipe insulation and refrigeration equipment.

Advantages of Polysurlyn Moisture Barrier Embossed Aluminum Coil in Insulating Materials

1.Excellent Moisture Barrier Performance: The Polysurlyn moisture barrier can effectively block moisture penetration, protect insulating materials from moisture damage, and reduce heat loss and material degradation caused by moisture.

2.Enhanced Corrosion Resistance: Aluminum itself has good corrosion resistance; when combined with the Polysurlyn layer, the overall durability is further improved, extending the service life.

3.Good Heat Reflectivity: The aluminum coil can effectively reflect heat, enhance insulation effects, and reduce energy consumption—this is particularly useful in air conditioning and heating systems.

4.Attractive Surface Finish: The embossed surface of the aluminum coil not only boosts its aesthetic value but also increases the material’s friction, reducing the risk of slipping. It is thus suitable for various construction and decoration scenarios.

5.Lightweight and Easy to Process: Embossed aluminum coils are usually lightweight, easy to cut and install, and suitable for quick on-site construction, saving time and labor costs.

6.Good Mechanical Strength: The embossing process enhances the surface strength of the aluminum coil, enabling it to withstand certain mechanical impacts and pressures, making it applicable in various environments.

7.Environmental Friendliness: Aluminum is recyclable and meets modern environmental protection requirements; using this material helps reduce environmental impact.

8.Versatility: It can be widely used in multiple fields such as construction, pipe insulation, and refrigeration equipment, with strong adaptability.

Applications of Polysurlyn Moisture Barrier Embossed Aluminum Coil

1.Industrial Insulation

Used as the outer sheath for oil and natural gas pipelines, particularly in pipeline projects exported to Middle Eastern countries.

Applied for insulating tanks and equipment in power plants and chemical plants; the 3003 aluminum alloy material is capable of resisting corrosion in desulfurization environments.

2.Construction Engineering

Utilized as the insulation layer and moisture barrier for roofs and walls, which prevents water vapor from penetrating and damaging the insulation materials.

Employed for insulation protection of cold storage facilities and air-conditioning systems; the orange peel pattern design takes both heat dissipation and mechanical strength into consideration.

Thermal Insulation,Polysurlyn Moisture Barrier,Polysurlyn Moisture Barrier Embossed Aluminum Coil

2025-03-17

Thermal Insulation Solution: Polysurlyn Moisture Barrier Embossed Aluminum Coil

2025-09-16