21

2025

-

10

The Lifespan of Aluminum Coils: What You Need to Know

Author:

Introducing The Lifespan of Aluminum Coils

Due to their lightweight nature, resistance to corrosion, and outstanding electrical conductivity, aluminum coils are indispensable in a multitude of industries. From construction and automotive manufacturing to electronics and packaging, these coils serve as crucial components that enhance the efficiency and durability of both products and structures. A common inquiry posed by manufacturers and end-users is: “What is the lifespan of an aluminum coil?” Understanding this factor is essential for ensuring optimal performance, safety, and cost-effectiveness in their applications. Among the diverse varieties of aluminum coils, color-coated aluminum coils are particularly noteworthy for their superior durability and appealing aesthetics.

Factors Influencing the Lifespan of Aluminum Coils

The service life of aluminum coils is affected by numerous factors. Understanding these variables is key to predicting their performance and planning maintenance schedules. The main factors are as follows:

1.Alloy Composition

Aluminum coils are available in different alloy grades, each with unique properties. For example, the 1050 alloy has high electrical conductivity, making it suitable for electrical applications, while the 5052 alloy offers greater strength and corrosion resistance, which is ideal for marine environments. The choice of alloy impacts the coil’s ability to resist environmental factors and mechanical stress, thus affecting its lifespan.

2.Environmental Conditions

Exposure to severe environmental conditions—such as extreme temperatures, high humidity, salt levels, and pollutants—can speed up the deterioration of aluminum coils. For instance, coils used in coastal areas are exposed to saltwater corrosion, which can significantly shorten their service life. Research indicates that aluminum in marine environments may corrode up to ten times faster than in rural areas.

3.Surface Treatments and Coatings

Surface treatments like anodizing, painting, or applying protective coatings can improve the durability of aluminum coils. For example, a color coating not only enhances the aesthetic appeal but also creates a protective barrier against corrosion and wear. Color-coated aluminum coils are a typical example, as they offer a longer service life even in challenging environments.

4.Mechanical Stress

Mechanical stresses such as bending, stretching, and vibration can damage the structural integrity of aluminum coils. Continuous or excessive stress may lead to fatigue cracks or deformation. Engineers must take these factors into account during the design phase to ensure the aluminum coil can withstand operational demands over time.

Common Types of Aluminum Coils & Their Service Lives

Aluminum coils come in various types, each designed for specific applications and with different lifespans. The main types are:

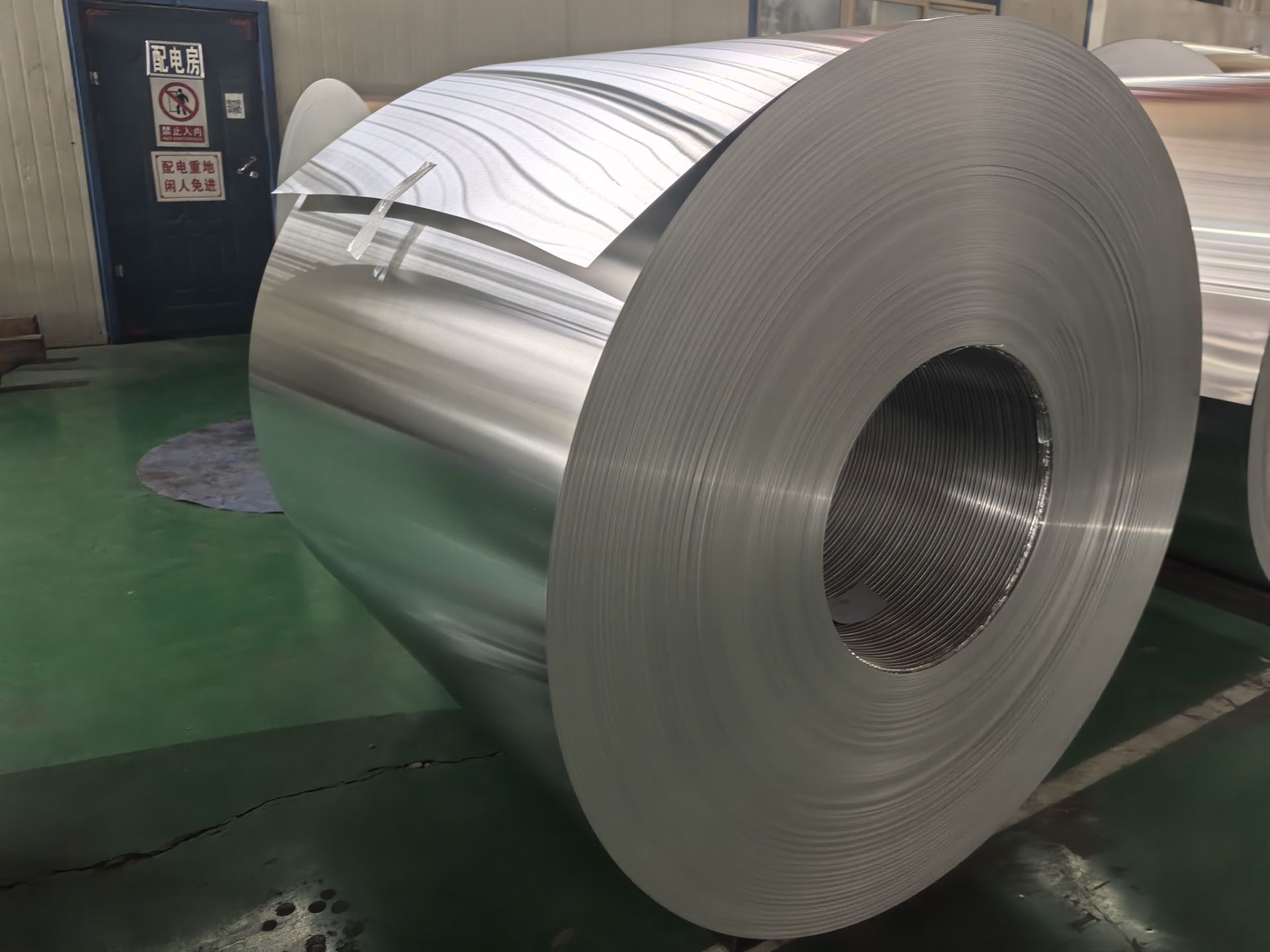

1.Mill Finish Aluminum Coils

These are basic aluminum coils without any surface treatment. They are commonly used in situations where surface appearance is not important. However, they are more prone to corrosion and may have a shorter lifespan in corrosive environments. Proper storage and handling are necessary to prevent early deterioration.

2.Anodized Aluminum Coils

Anodizing strengthens the natural oxide layer on aluminum, improving its corrosion resistance and surface hardness. Anodized coils are suitable for architectural applications and can last for several decades with minimal maintenance. This process also allows for coloring, providing flexibility in terms of appearance.

3.Color Coated Aluminum Coils

These coils are coated with paints or resins (such as PVDF or PE coatings), which offer excellent protection against UV radiation, weathering, and corrosion. Depending on the coating quality and environmental conditions, color-coated aluminum coils can last anywhere from 20 to 50 years. They are widely used in roofing, cladding, and ceiling applications.

The Durability of Color Coated Aluminum Coils

Color coated aluminum coils have gained immense popularity owing to their superior durability and aesthetic charm. The coating functions not only as a decorative layer but also as a protective barrier against environmental hazards. Here, we delve into the various factors that contribute to their extended lifespan:

1.Quality of Coating Material

The longevity of color coated aluminum coils is primarily determined by the quality of the coating material used. For instance, PVDF coatings are renowned for their exceptional resistance to ultraviolet radiation and chemical corrosion, boasting a lifespan that can exceed 30 years. In comparison, PE coatings offer a more moderate lifespan of approximately 15 to 20 years, making them a more cost-effective option. Therefore, selecting the appropriate coating material according to the specific application and environmental conditions is essential for optimal performance.

2.Coating Application Process

The method used to apply the coating affects its adhesion and uniformity. Advanced techniques like continuous coil coating ensure the protective layer is applied evenly, eliminating weak points that could cause early failure. Proper curing of the coating is also essential to achieve the best performance.

3.Environmental Resistance

Color coated aluminum coils are engineered to endure a wide range of environmental conditions. In industrial regions characterized by elevated pollution levels, these coils may encounter acidic or alkaline substances, necessitating coatings that can effectively resist chemical corrosion. In coastal environments, the ability to withstand salt spray is crucial. To ensure their performance in specific settings, these coils undergo rigorous testing and certification in compliance with international standards, such as ASTM or ISO.

Maintenance Practices to Extend Lifespan

To ensure the longevity of aluminum coils, proper maintenance is crucial. Conducting regular inspections and taking prompt action can help avert minor issues from escalating into significant problems. The following best practices are recommended:

1.Routine Inspections

Regular checks for signs of wear, corrosion, or mechanical damage can help identify potential issues early. Inspections should focus on surface integrity, coating condition, and any signs of distortion or fatigue.

2.Cleaning Procedures

Removing contaminants like dirt, debris, and chemical residues helps maintain the protective properties of the coil’s surface. For color-coated coils, mild cleaning agents that do not scratch or chemically damage the coating should be used.

3.Protective Measures

In environments with a high risk of corrosion, additional protective measures—such as applying sealants or barrier coatings—can be beneficial. It is also advisable to store coils in controlled environments to minimize exposure to moisture and pollutants.

Utilization and Anticipated Lifespans Across Various Environments

The anticipated lifespan of aluminum coils can differ based on their specific applications and the environmental conditions in which they are utilized. Below, we present several common applications along with their estimated service lives:

1.Construction Industry

In roofing and facade cladding, color coated aluminum coils can last 20 to 50 years. Their long lifespan is due to the protective coatings and the metal’s inherent corrosion resistance. For example, using high-quality coated sheets ensures durability even in extreme weather conditions.

2.HVAC Systems

Aluminum coils in heating, ventilation, and air conditioning (HVAC) systems are essential for thermal conductivity. With proper maintenance, these coils can operate efficiently for 15 to 20 years. Regular cleaning to prevent debris buildup and the use of corrosion inhibitors can extend their operational lifespan.

3.Automotive Industry

In automotive manufacturing, aluminum coils are used for body panels and heat exchangers. Coated aluminum coils resist corrosion from road salts and environmental pollutants. Their lifespan usually matches the vehicle’s service life, often exceeding 10 years with little deterioration.

Conclusion

The service life of aluminum coils varies significantly based on factors such as alloy composition, environmental exposure, surface treatment, and maintenance practices. While mill-finished aluminum coils may meet specific application requirements, color-coated aluminum coils offer superior long-term performance due to their enhanced durability—particularly in harsh environments. By understanding these variables and implementing appropriate maintenance strategies, manufacturers and end-users can ensure aluminum coils deliver decades of reliable service across diverse applications. The properties of aluminum continue to make it the material of choice across industries seeking durability and sustainability.

Lifespan of Aluminum Coils,Aluminum Coils,Color Coated Aluminum Coils

2025-03-17

The Lifespan of Aluminum Coils: What You Need to Know

2025-10-21