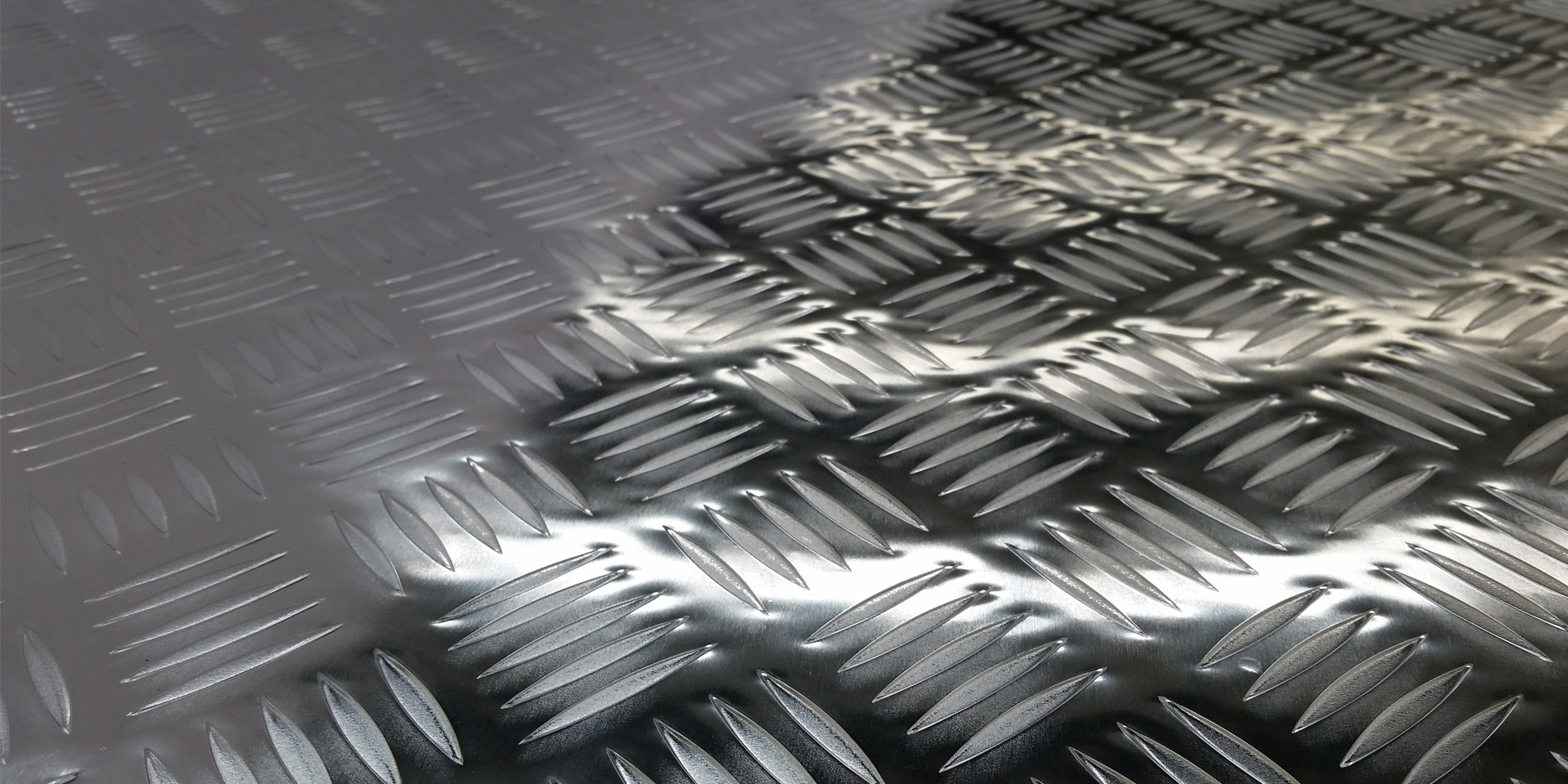

5052 Aluminum Checkered Plate

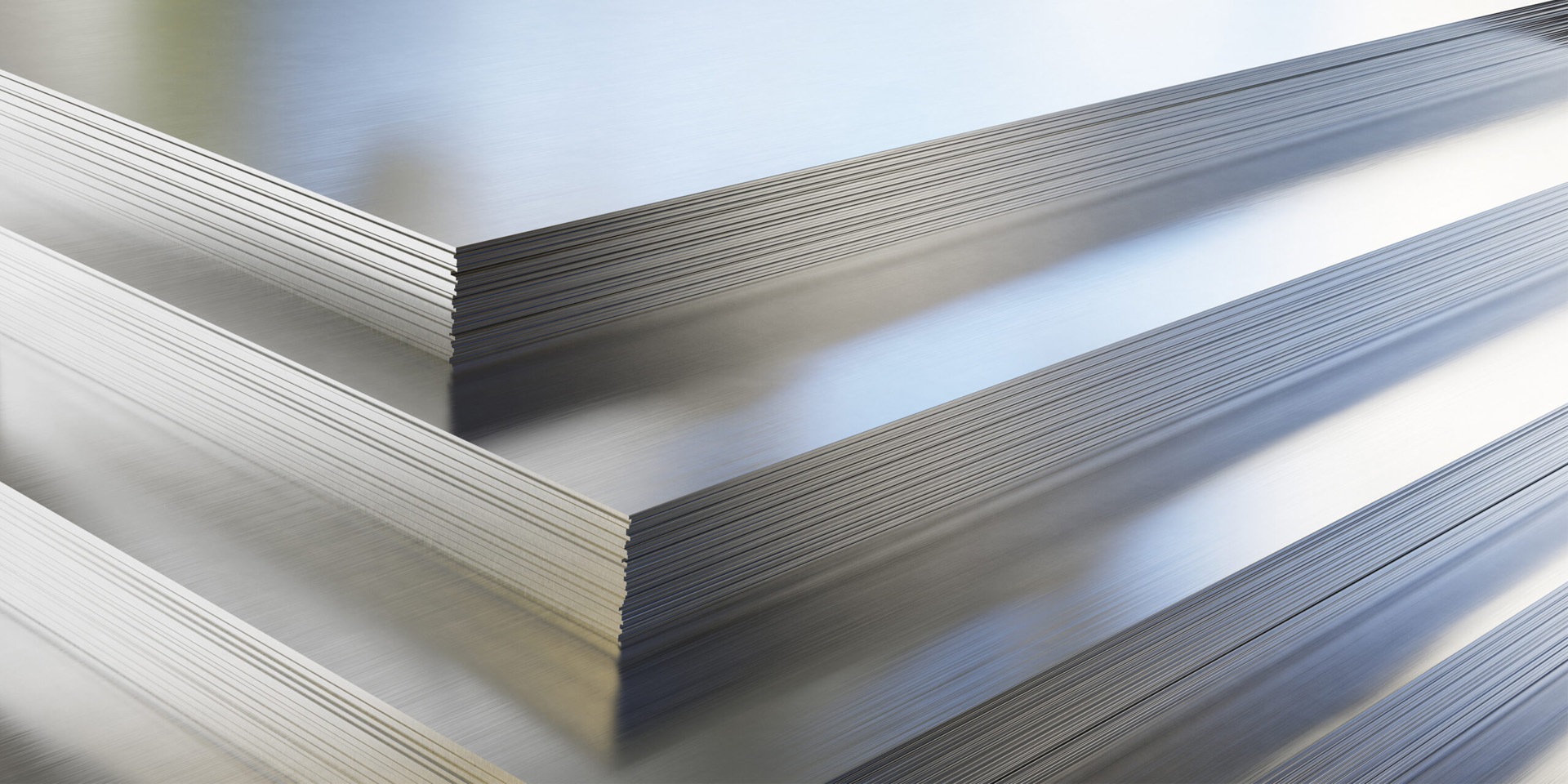

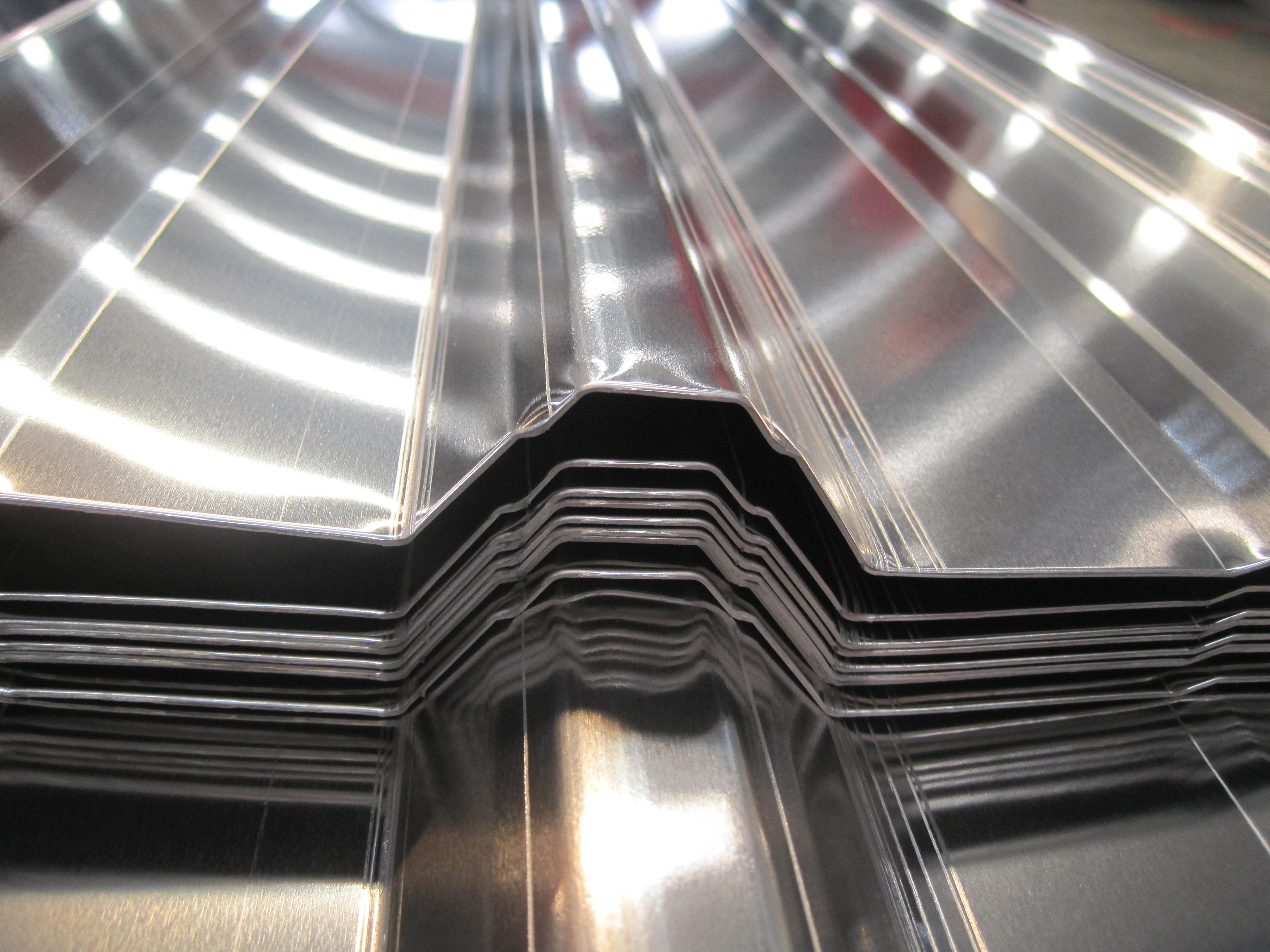

5052 aluminum checkered plate is a high-performance aluminum-magnesium (Al-Mg) alloy tread plate, characterized by a raised pattern (such as diamond, or 5 bars) on its surface. As a 5000 series alloy, it contains approximately 2.5% magnesium as the main alloying element, with trace amounts of chromium to enhance corrosion resistance and strength.

MESSAGE

Overview

The 5052 aluminum checkered plate is an AL-Mg alloy aluminum plate with magnesium as the primary alloying element . It is one of the most widely used rust-resistant aluminum alloys. Its surface is processed to form raised patterns such as five bars, diamonds, or pointers, combining anti-slip, decorative, and functional properties for applications in transportation, construction, and industry.

Specification

Item: 5052 Aluminum Checkered Plate

Temper: O,H22,H32,H114

Thickness: 1mm-6mm

Width: 1000mm-2200mm

Length: 1000mm-6000mm

Surface: Bright/Mirror Surface and Normal etc

Pattern: a. Big five bars aluminum checkered plate

b.Small five bars aluminum tread plate

c.Aluminum diamond plate, also called one bar or pointer aluminum tread plate

d.Two bars aluminum chequered plate

e.Three bars aluminum checkered plate

Feature

1.High Strength & Fatigue Resistance

With a tensile strength of 170-305 MPa and yield strength ≥90 MPa, 5052 is ideal for load-bearing structures like ship decks and vehicle floors.

2.Superior Corrosion Resistance

Magnesium forms a dense oxide layer, providing resistance to seawater, acids, and alkalis—perfect for offshore platforms and chemical plants.

3.Excellent Anti-Slip Performance

The five-bar pattern enhances friction, outperforming flat plates in wet or oily conditions for improved safety.

4.Good Processability

Welding: Suitable for gas, arc, and resistance welding, with seam strength reaching 90%-95% of the base metal.

Forming: Excellent cold stamping in annealed (O) state; H32/H34 states are ideal for bending and deep drawing.

5.Versatile Surface Treatments

Anodizing, painting, and electrophoresis allow matte, glossy, or colored finishes.

Application

1.Marine & Coastal Engineering

Ship decks, gangways, and offshore platform walkways: Resists saltwater corrosion and provides secure footing for crew.

Coastal building facades or railings: Withstands high humidity and salt spray.

2.Transportation Industry

Truck/trailer flooring and side steps: Handles heavy cargo loads and frequent impact; anti-slip for loading/unloading.

Bus/metro interior floors: Resists wear from passenger traffic and easy to clean.

3.Construction & Architecture

Stair treads, ramps, and industrial platforms: Ensures safety in factories, warehouses, or public buildings.

Decorative wall panels or ceiling cladding: Combines functionality with a modern metallic aesthetic.

4.Industrial & Commercial Use

Factory floors and equipment covers: Resists oil, chemical spills, and mechanical wear.

Cold storage or freezer flooring: Withstands low temperatures without embrittlement.

5.Outdoor & Recreational Applications

Camping trailer floors or RV steps: Lightweight, corrosion-resistant, and anti-slip for outdoor use.

Poolside decks or marina walkways: Resists water damage and provides safe traction around water.

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!