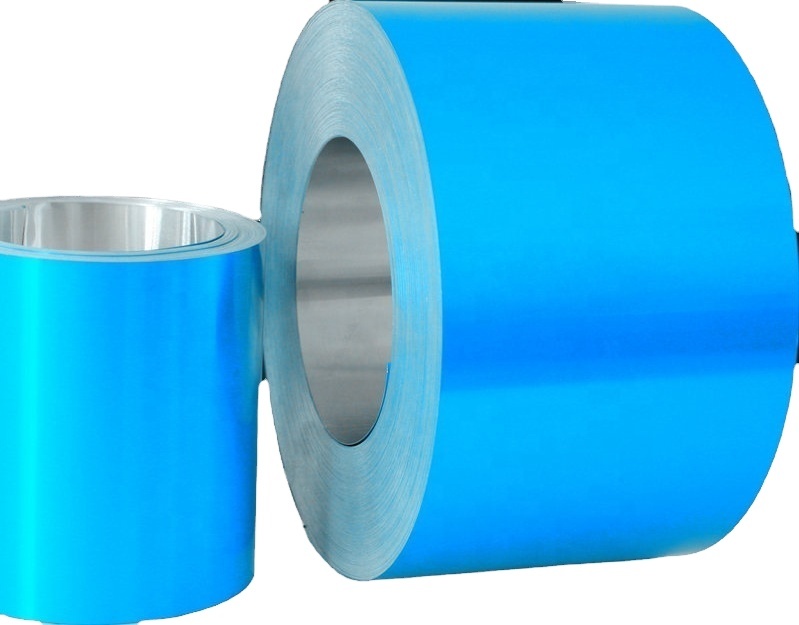

3003 Stucco Embossed Aluminium Coil

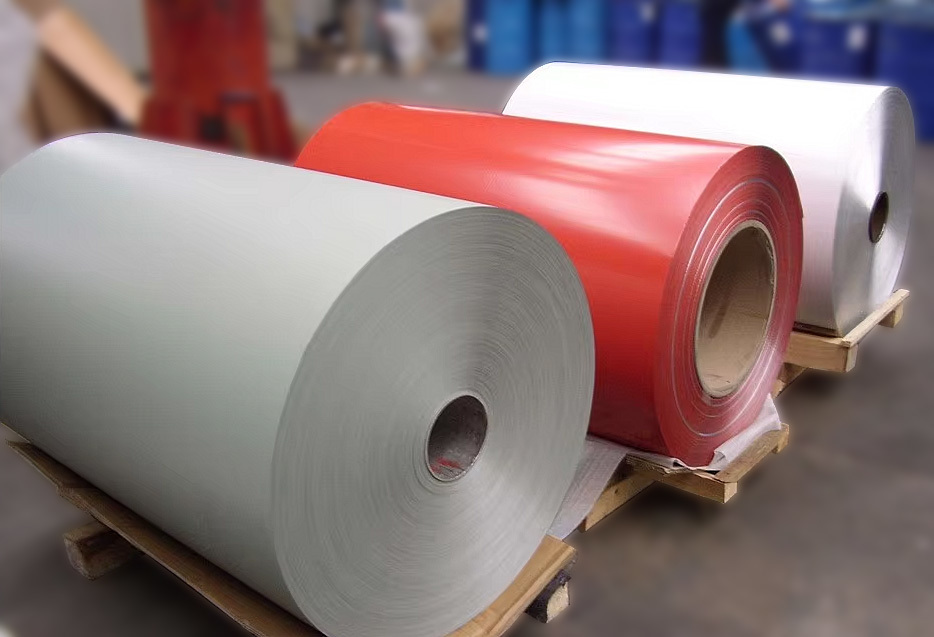

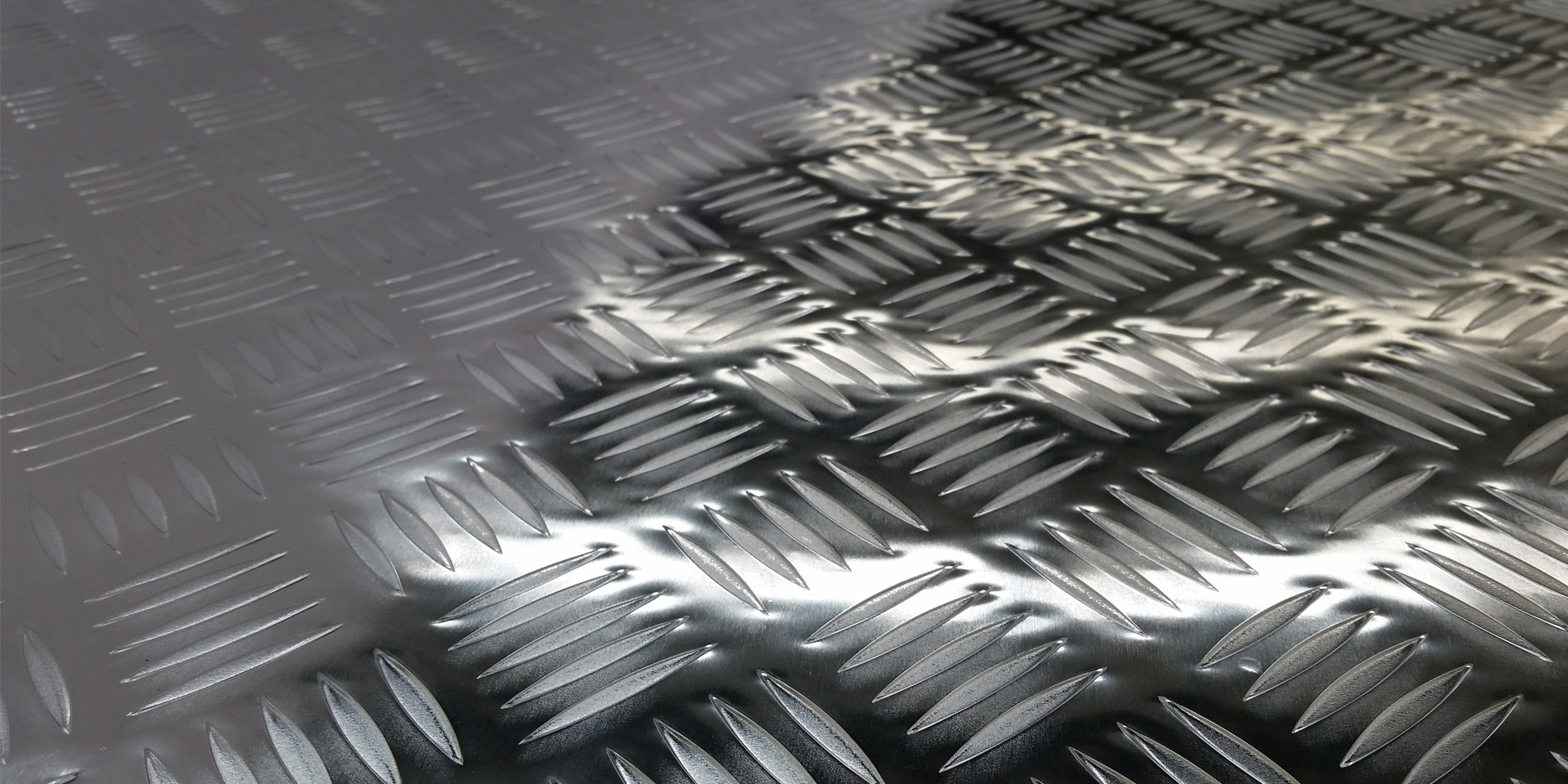

The 3003 stucco embossed aluminum coil is made of 3003 aluminum alloy (Al-Mn series with a manganese content of about 1.0 - 1.5%). Unique embossed patterns, such as orange peel and diamond patterns, are formed on the surface through processes like roll embossing. This aluminum coil combines the good properties of 3003 alloy with the special advantages brought by embossing.

MESSAGE

Overview

3003 stucco embossed aluminium coil is a non-heat-treatable Al-Mn alloy (3000 series) with manganese (Mn) as the primary alloying element (content: 1.0–1.5%). It combines the excellent corrosion resistance of pure aluminum (similar to 1000 series) with higher strength and better formability than industrial pure aluminum (e.g., 1060). The stucco embossing process creates a textured surface (e.g., orange peel, diamond) to enhance aesthetics, reduce reflectivity, and improve anti-slip properties. Widely used in decorative, industrial, and functional applications, it is a cost-effective solution for projects requiring medium strength, corrosion resistance, and easy processing.

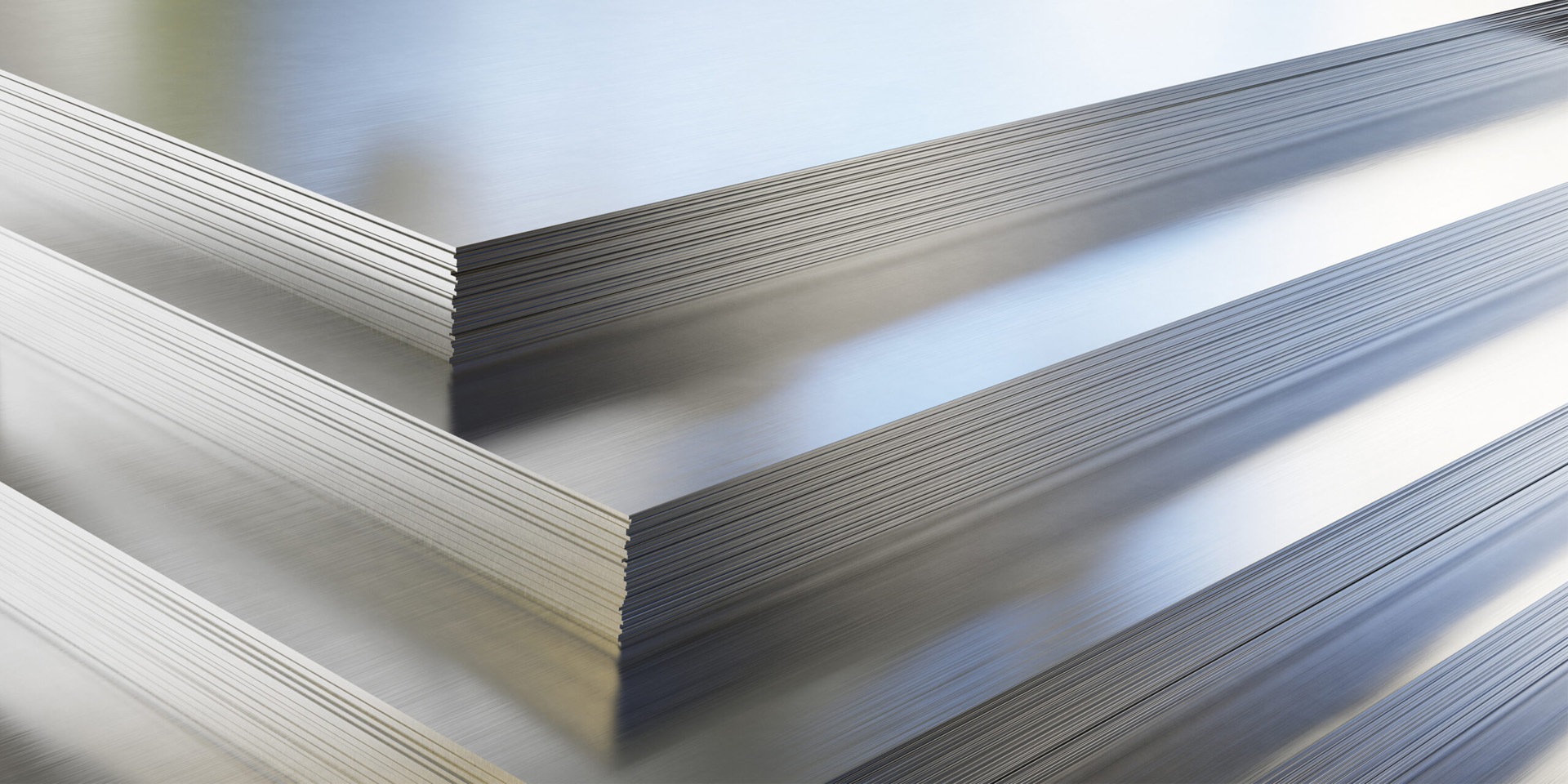

Specification

Alloy: 3003 Stucco Embossed Aluminium Coil

Temper: H12,H14,H16,H18,H22 ,H24,H26,H28

Thickness: 0.2mm-1.5mm

Width: 20mm-1600mm

Surface Types: orange peel,variant orange peel,mirror finish orange peel patterns,diamond,hammered,etc

Feature

1.Moderate Strength: Compared with pure aluminum, the strength of 3003 alloy is increased by about 20%, with a tensile strength of up to 140 - 180MPa. It can withstand certain external forces, ensuring the structural stability of products.

2.Good Corrosion Resistance: The manganese element in the alloy enhances corrosion resistance. It can be used for a long time without rusting in ordinary environments and some non - highly corrosive scenarios, with an outdoor service life of 10 - 15 years.

3.Outstanding Decorative Property: The embossed patterns endow the aluminum coil with unique textures and visual effects, improving the aesthetics of products and adding an artistic atmosphere to various applications.

4.Excellent Workability: It is easy to bend, stamp, cut and perform other processing operations, and can be made into various complex shapes and specifications to meet different design requirements.

Application

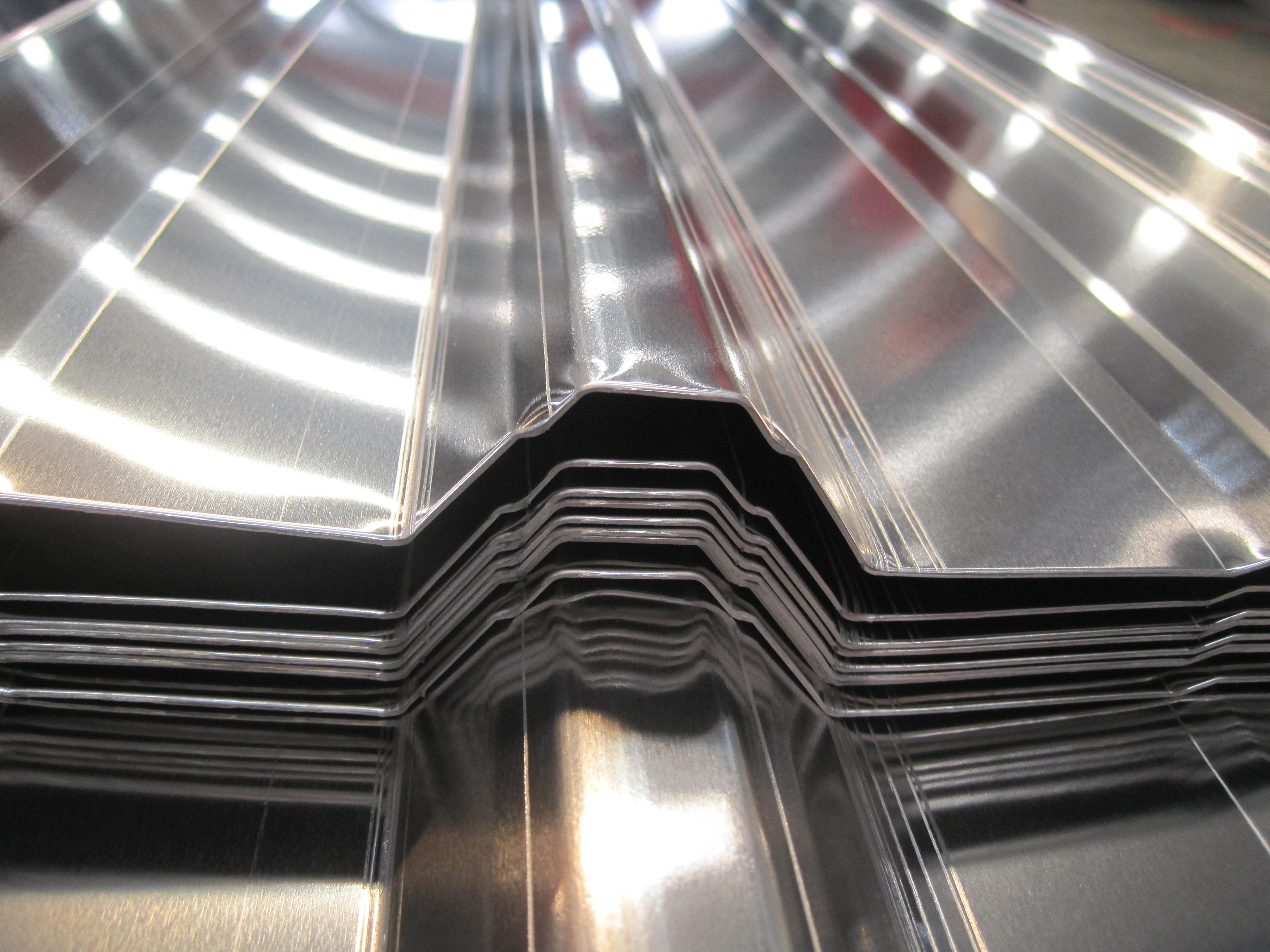

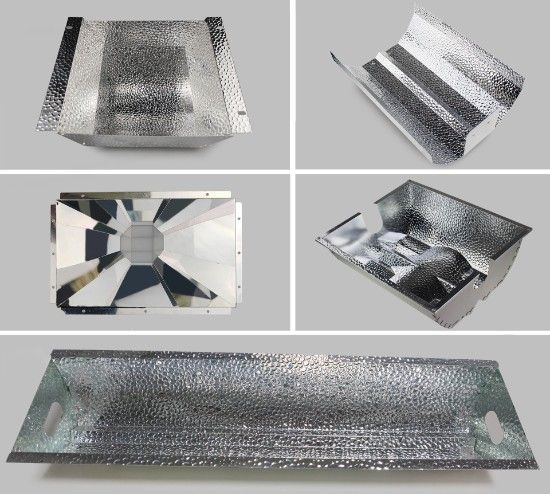

1.Construction Field: Used for exterior wall decorative panels and ceiling suspended ceilings to enhance the three - dimensional and modern look of buildings; it can also be used in ventilation ducts to improve durability and aesthetics.

2.Home Appliance Industry: The inner linings and outer shells of refrigerators and freezers are both beautiful and scratch - resistant; the protective panels of air conditioner outdoor units use its corrosion resistance to extend the service life.

3.Transportation: Automotive interior parts (such as door interior panels) enhance the interior texture of vehicles; the body side panels of trucks and trailers reduce weight while ensuring strength.

4.Industrial Manufacturing: The outer protective sleeves of chemical pipelines resist slight corrosion; the decorative panels of industrial equipment improve the overall image of the equipment.

MESSAGE

Please tell us what you need and we will get in touch with you as soon as possible!

Note: Items marked with * are mandatory, thank you!